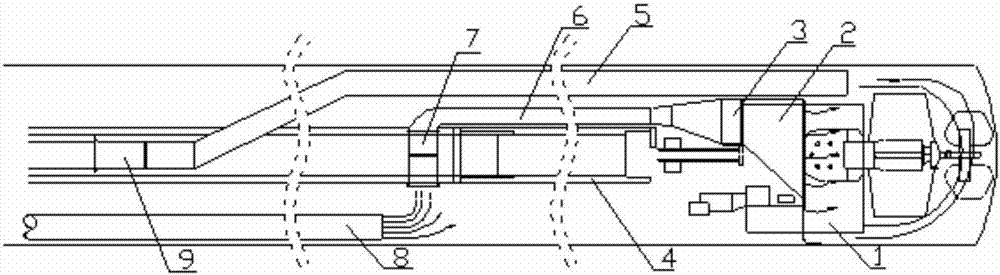

Dust collecting and dust removing system for wind curtain in fully mechanized excavation face

A dust removal system and working face technology, applied in the field of coal mines, can solve problems such as adjusting the wind speed and volume of the flow field, and extracting dust-laden air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0047] The present invention uses N 3 The seven-story belt middle roadway excavation face is the research object, and the roadway face is located in the northwest of Xiaoming minefield. The south is adjacent to the industrial square protection coal pillar line and the North No. 1 Mining Area and the South No. 1 Mining Area, the north is adjacent to the Daming Coal Mine, and the west is N 3 The middle lane of the seven-story track, and the east is the unmined area. The western part of the surface of the mining area is Daxiaojiangtun. The surface is mostly covered by farmland and woods, and the average surface elevation is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com