Electric control box

A technology for electric control boxes and boxes, which is applied in the field of electric control boxes, can solve the problems of low assembly efficiency, poor assembly, and additional locks, etc., and achieve the effect of simple structure and convenient and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Combine below Figure 1 to Figure 8 The technical solution provided by the present invention is described in more detail.

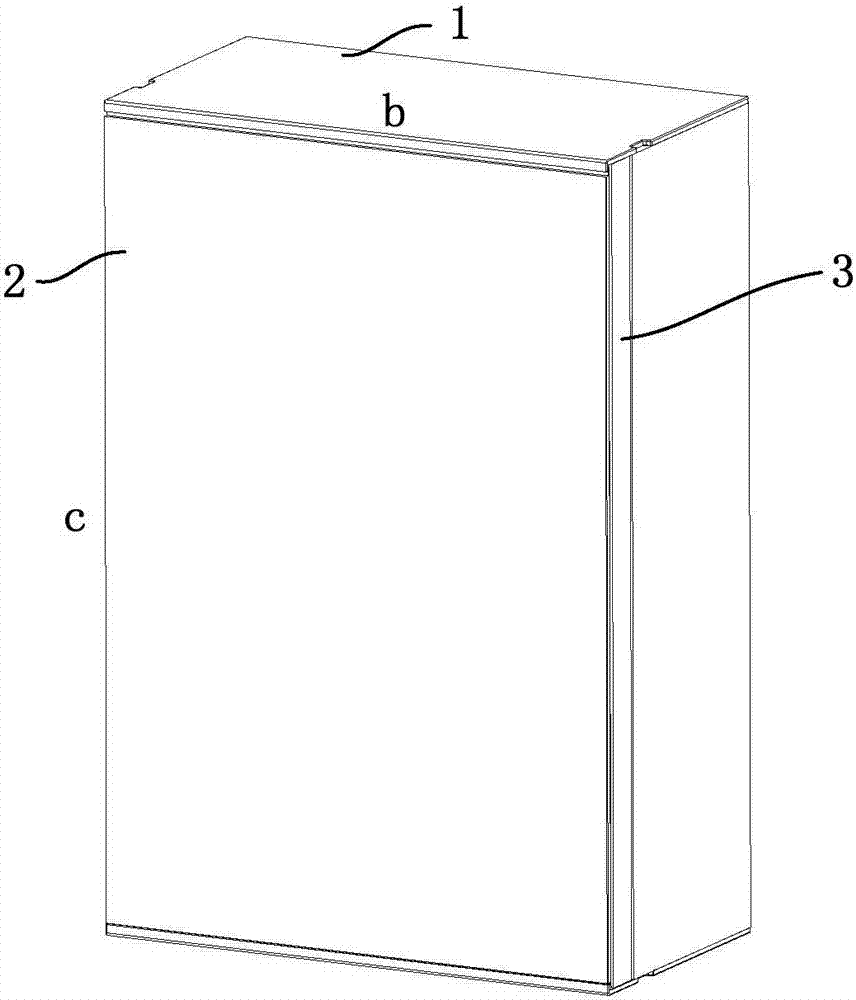

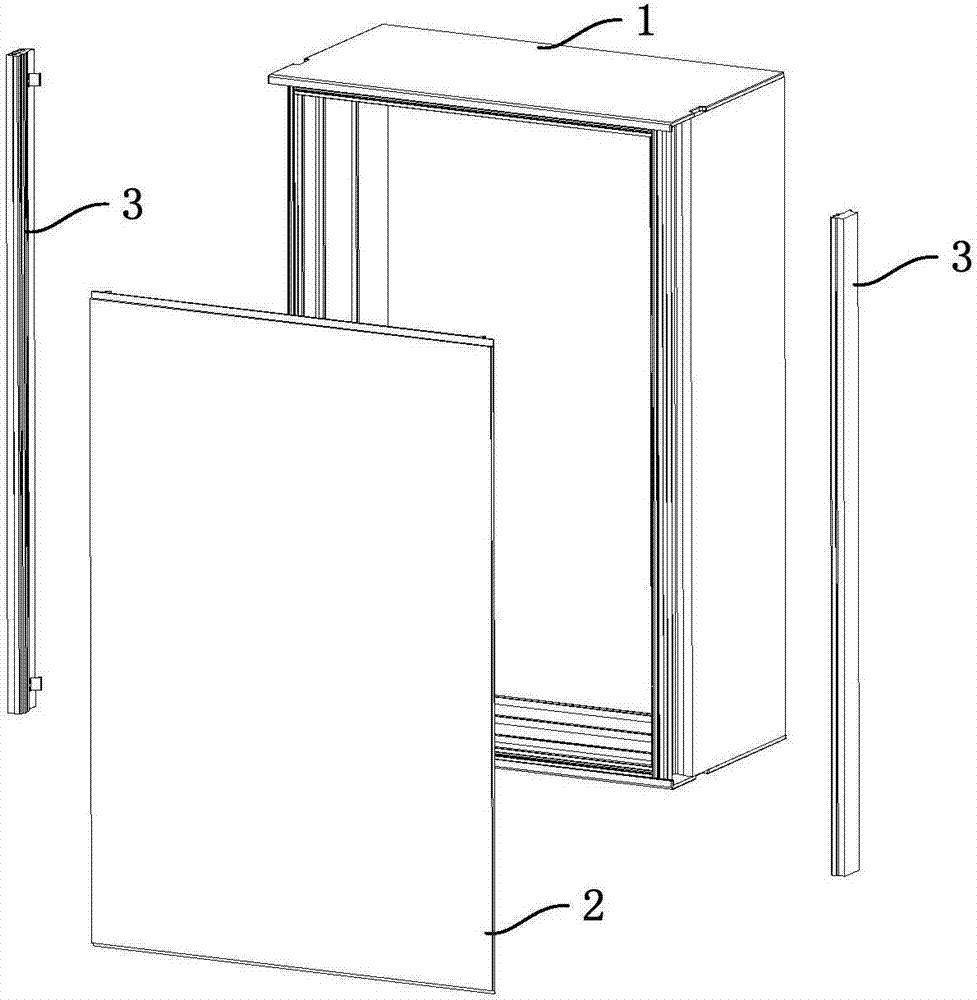

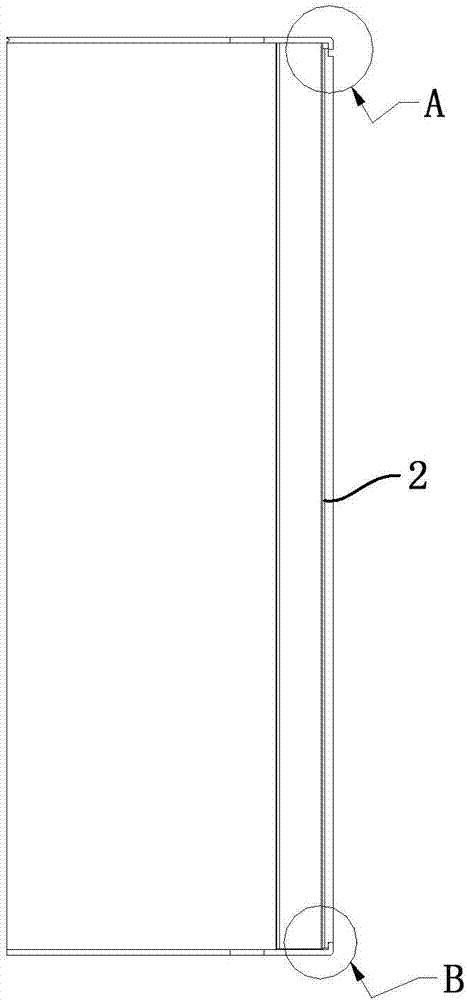

[0035] see Figure 1 to Figure 5 , The embodiment of the present invention provides an electric control box, including a box body 1 and a box cover 2, and the two opposite edges of the box body 1 and the box cover 2 are plugged and connected. in image 3 The shown upper and lower edges form the plug-in structure as an example. The box body 1 and the box body 2 are formed with mutually matched plug-in structures on the upper edges, for example, one of them is provided with a protrusion, and the other is provided with a groove. The box body 1 and the box body 2 are also formed with interfitting plug-in structures on the lower edge, for example, one of them is provided with a protrusion, and the other is provided with a groove.

[0036] After adopting the above connection method, there are two positions between the box body 1 and the box cover 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com