CF(color filter) substrate and manufacturing method thereof and alignment film alignment angle measuring method

A production method and technology of alignment film, which are applied in the fields of instruments, nonlinear optics, optics, etc., can solve the problems of inability to realize real-time monitoring of products, inaccurate measurement results, and defective batch products, etc., to simplify the alignment angle measurement method, realize Real-time monitoring and effect of simplified alignment angle measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical means adopted by the present invention and its effects, the following describes in detail the preferred embodiments of the present invention and the accompanying drawings.

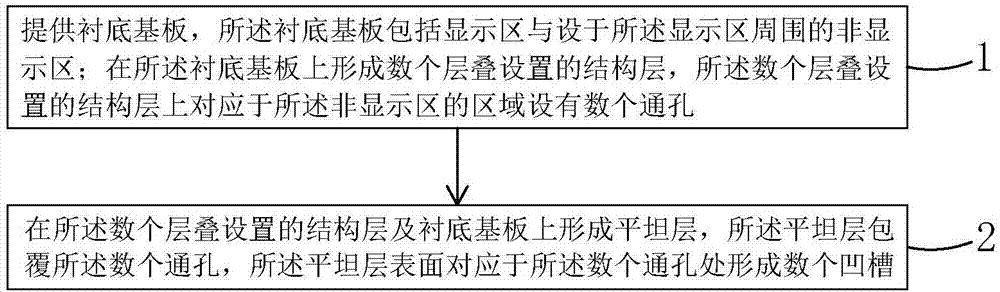

[0035] See figure 2 , The present invention first provides a method for manufacturing a CF substrate, including the following steps:

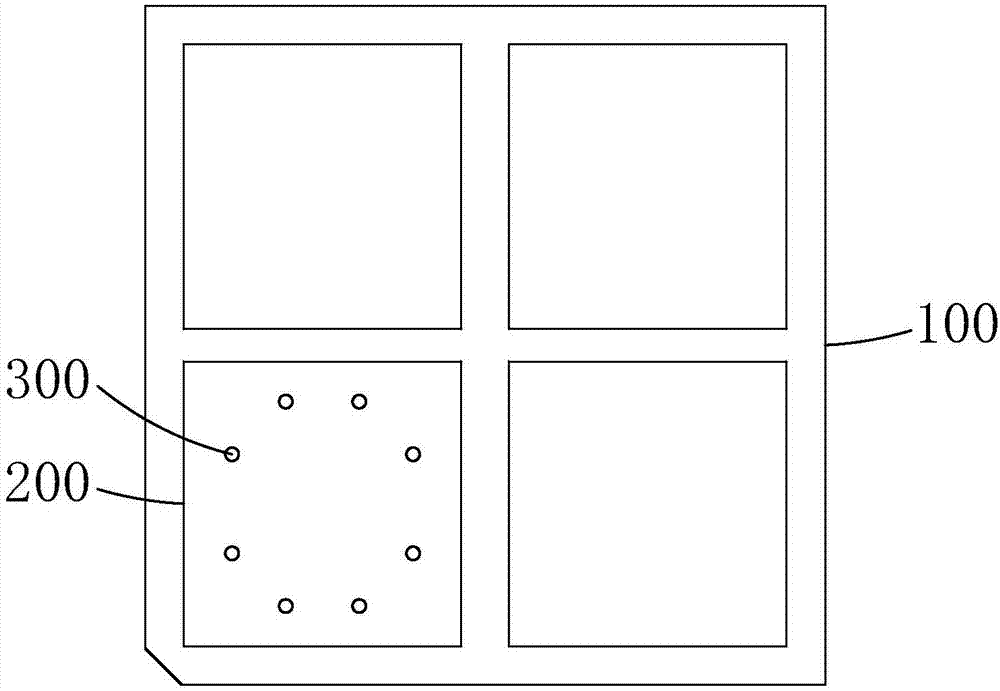

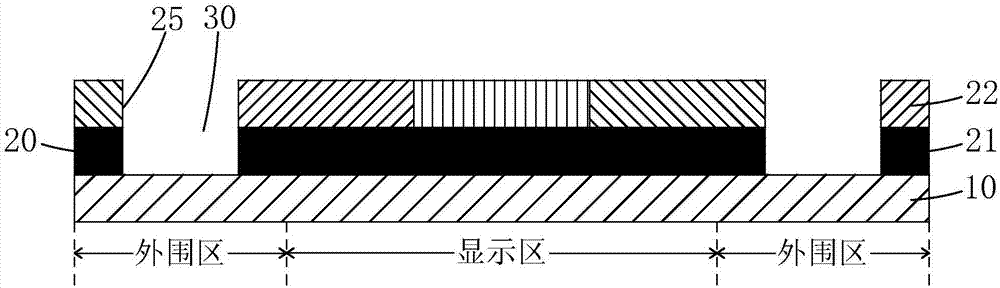

[0036] Step 1, such as image 3 As shown, a base substrate 10 is provided, and the base substrate 10 includes a display area and a non-display area provided around the display area;

[0037] A plurality of stacked structural layers 20 are formed on the base substrate 10, and a plurality of through holes 30 are provided on the plurality of stacked structural layers 20 corresponding to the non-display area.

[0038] Specifically, in the step 1, the method for manufacturing the plurality of through holes 30 is as follows: in the manufacturing process of the plurality of stacked structural layers 20, each structural layer 20 is formed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com