A Directional High Gain Microstrip Antenna

A microstrip antenna and high-gain technology, which is applied in the direction of antenna, antenna grounding device, antenna grounding switch structure connection, etc., can solve the problems of small gain and poor directivity, and achieve increased gain, good symmetry, and suppression of backward radiation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

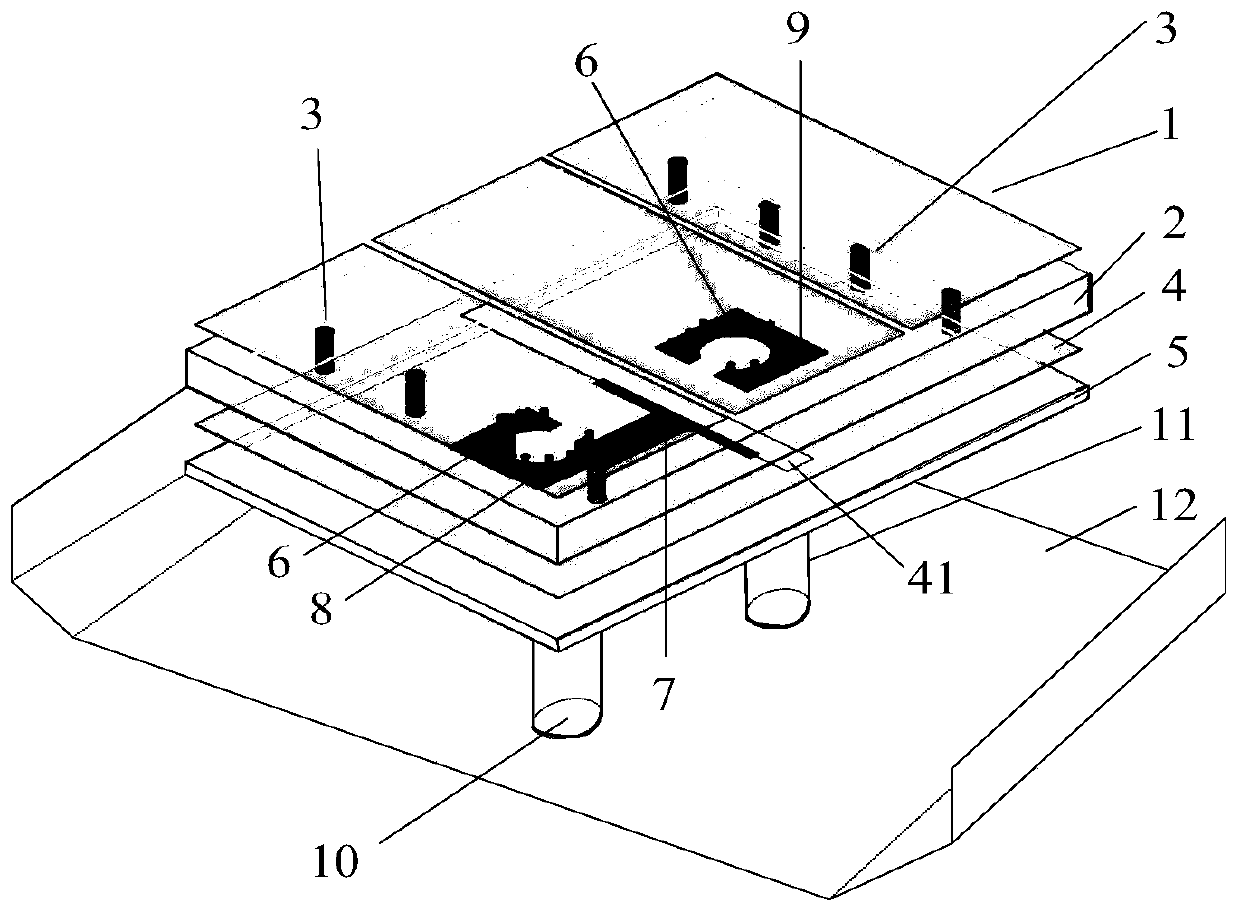

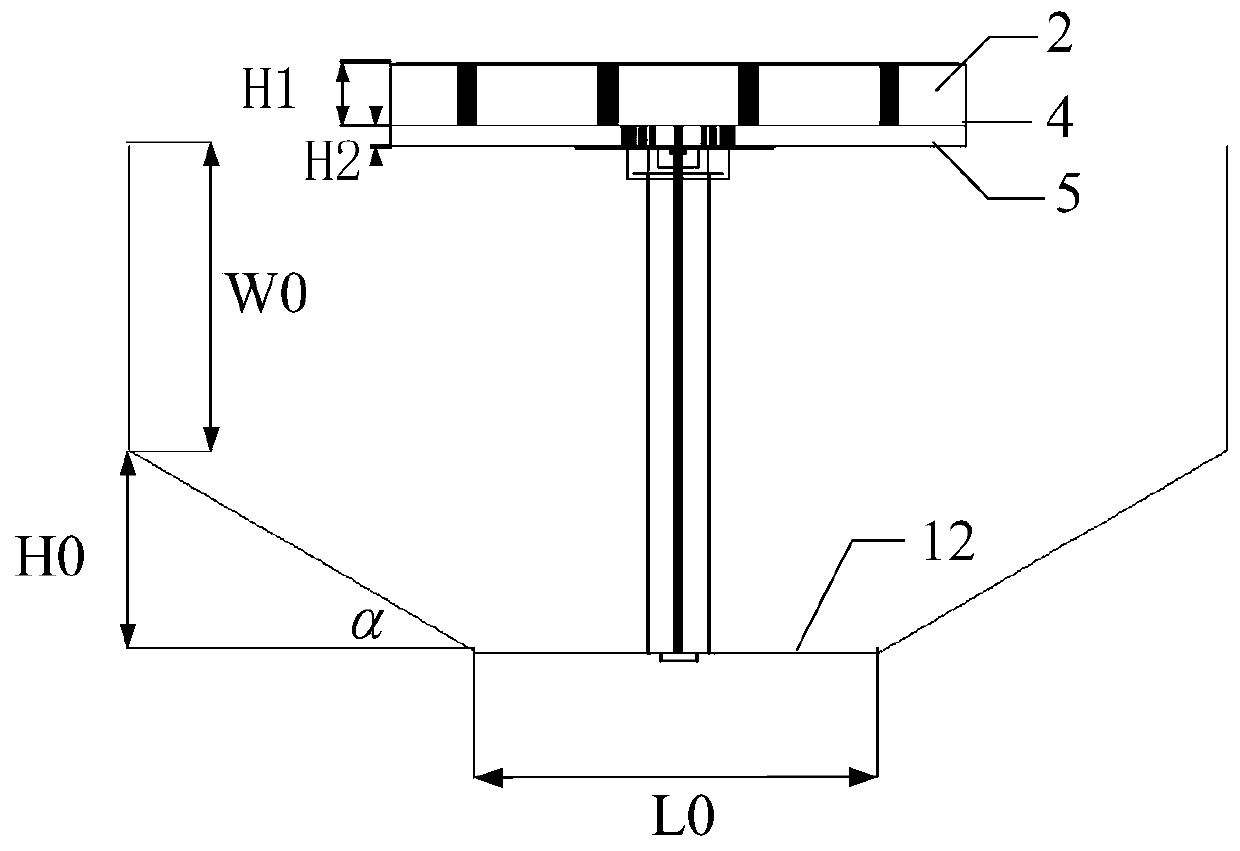

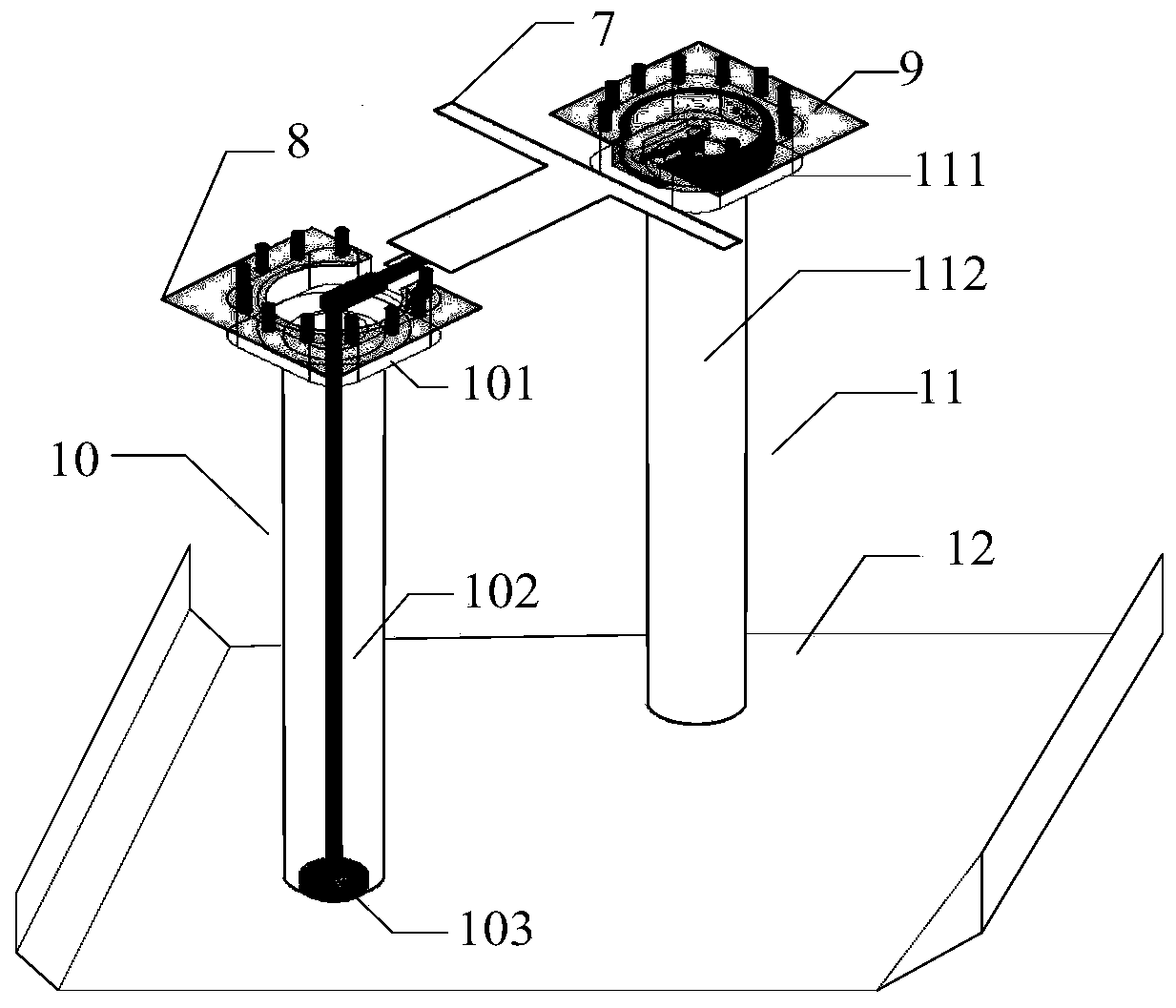

[0031] refer to figure 1: A directional high-gain microstrip antenna, comprising a radiation unit 1, an upper dielectric substrate 2, a first metallized via hole 3, a floor 4, a lower dielectric substrate 5, a second metallized via hole 6, and a T-shaped microstrip line 7 , the first metal pad 8 and the second metal pad 9; the upper dielectric substrate 2 and the lower dielectric substrate 5 form an up and down stacked structure, and the radiation unit 1 is composed of three rectangular patches arranged in sequence, printed on the upper dielectric substrate 2 The floor 4 is printed on the upper surface of the lower dielectric substrate 5, the center of which is provided with a rectangular slit 41, and the T-shaped microstrip line 7 is printed on the center of the lower surface of the lower dielectric substrate 5 for transmitting radio frequency signals , and radiate electromagnetic energy outward through the rectangular slit 41, and simultaneously excite the radiation unit 1 a...

Embodiment 2

[0038] Embodiment 2, the structure of this embodiment is identical with the structure of embodiment 1, and following parameter has been adjusted:

[0039] Three rectangular patches arranged in sequence, the distance between the adjacent patches is S1=0.2mm, the size of each rectangular patch is the same, the long side size L1=15mm, the wide side size W1=7.2mm; floor 4 Long side size L2=22mm, wide side size W2=15mm, rectangular slit 41, its long side size L3=11mm, wide side size W3=0.75mm; T-type microstrip line 7, the width W4= of small impedance microstrip line 2.2mm, length L4=3.7mm, L5=1.85mm; the width of the high-impedance microstrip line is W5=0.58mm, and the length is L6=8mm.

Embodiment 3

[0040] The structure of embodiment 3 is identical with the structure of embodiment 1, and following parameter has been adjusted:

[0041] Three rectangular patches arranged in sequence, the distance between the adjacent patches is S1=0.75mm, the size of each rectangular patch is the same, the long side dimension L1=60mm, the wide side dimension W1=24.5mm floor 4 length Side size L2=75mm, wide side size W2=60mm, rectangular slit 41, its long side size L3=42mm, wide side size W3=4.5mm; T-shaped microstrip line 7, the width of small impedance microstrip line W4=3mm , length L4=6.65mm, L5=2.85mm; the width of the high-impedance microstrip line is W5=0.75mm, and the length is L6=16mm.

[0042] Effect of the present invention can be further explained in conjunction with simulation result:

[0043] 1. Simulation content:

[0044] 1.1 Utilize the commercial simulation software HFSS_15.0 to simulate the return loss parameters of the above-mentioned embodiment 1, the results are as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com