Uniform stirring apparatus for decoration materials

A decorative material, italic technology, applied in mixers with rotary stirring devices, transportation and packaging, mixer accessories, etc., can solve problems such as difficulty in pouring out the mixed raw materials, uneven stirring strength, and influence on the painting effect, etc., to reduce The effect of manual labor, not easy to splash, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

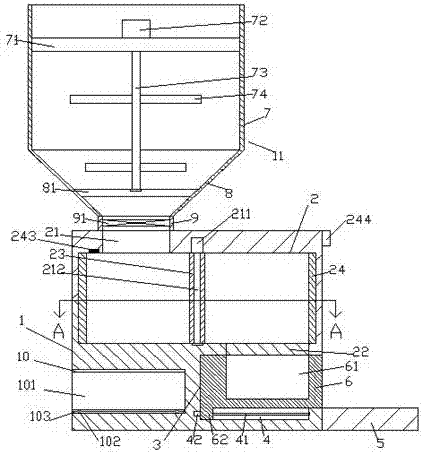

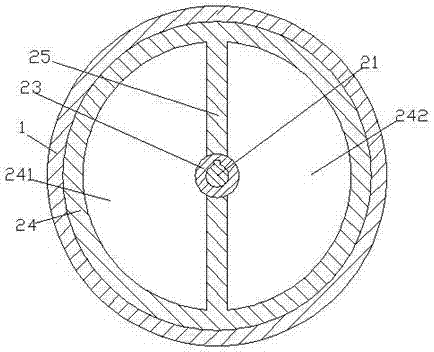

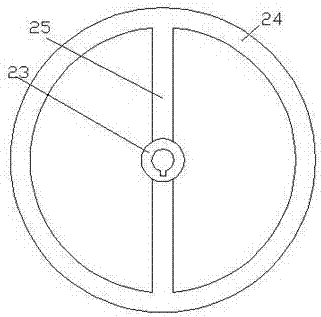

[0021] Such as Figure 1-Figure 6 As shown, a decorative material stirring device of the present invention includes a cylinder 1 and a container 11 arranged above the cylinder 1, the container 11 includes a first oblique body 7, and is arranged on the first oblique body 7 at the bottom of the second oblique body 8 and the third oblique body 9 arranged at the bottom of the second oblique body 8, the cylinder body 1 is provided with a first sliding chamber 2, and the left top of the first sliding chamber 2 is provided with a The third oblique body 9 communicates with the first port 21, the bottom of the right side of the first slide chamber 2 is provided with a second port 22, and the cylinder body 1 at the bottom of the second port 22 is provided with The second sliding chamber 3, the cylinder body 1 at the bottom of the second sliding chamber 3 is provided with a sliding connection groove 4, and the first sliding chamber 2 is provided with a sleeve 24 for steering fit connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com