A method of improving sealing performance of butterfly valve and structure of high-sealing butterfly valve

A high-sealing, butterfly valve technology, applied in shaft seals, lift valves, valve details, etc., can solve problems affecting the normal use of butterfly valves, poor sealing performance, and reduced sealing performance of butterfly valves, so as to ensure sealing performance, improve sealing performance, and improve Effect of Shaft End Sealing Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

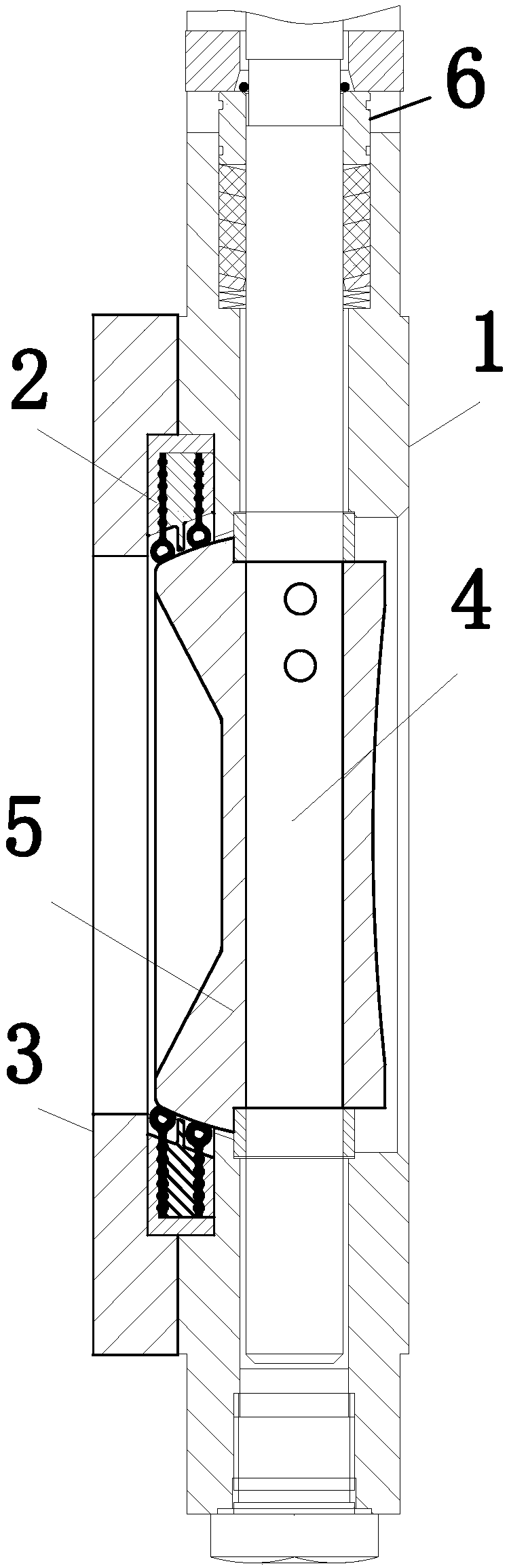

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for limiting the present invention.

[0025] Example. A method for improving the sealing performance of a butterfly valve. A butterfly valve sealing device is arranged between a valve seat and a valve body to seal and cooperate with a valve clack; a shaft sealing device is arranged on the valve body to seal with a valve stem.

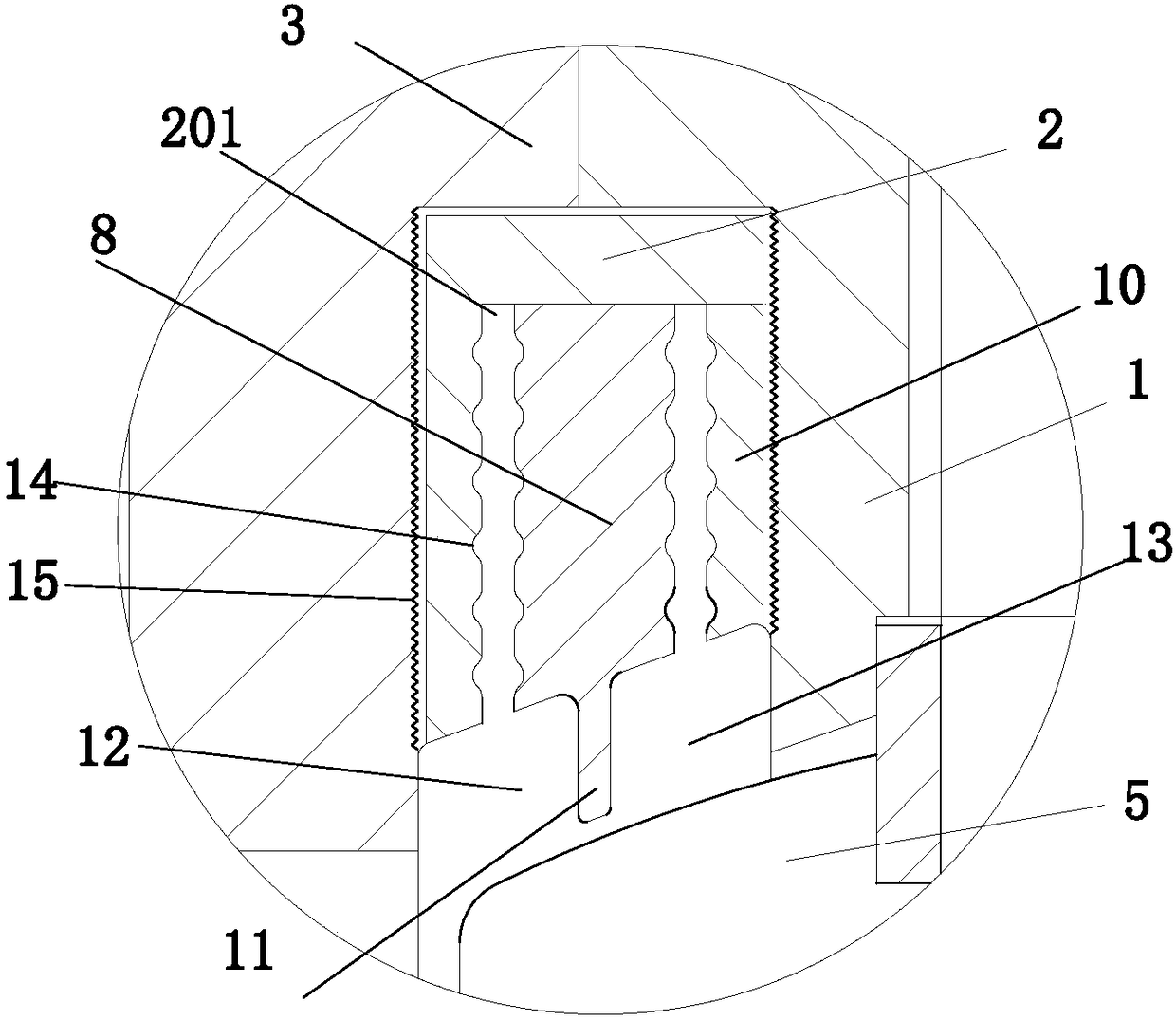

[0026] The butterfly valve sealing device divides the valve cover and the valve body into two mutually independent first sealing chambers and second sealing chambers through the partition plate, and sets the first sealing chamber between the valve cover and the valve body respectively. The first sealing ring and the second sealing ring corresponding to the chamber and the second sealing chamber serve the purpose of double sealing.

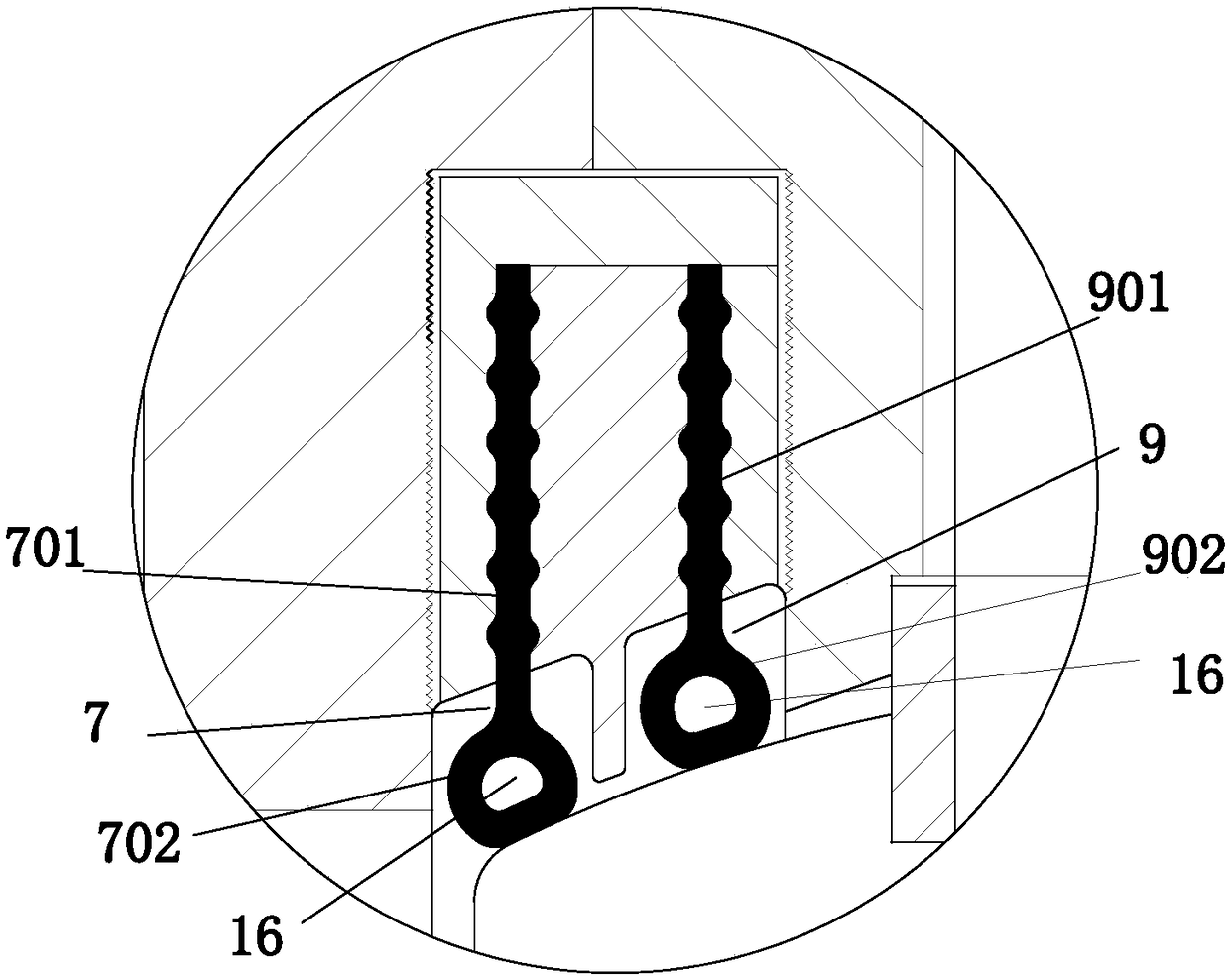

[0027] The shaft sealing device squeezes the sealing packing into a V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com