Method for reducing the regenerative chatter of chip-removal machines

A technology of cutting machine and chatter, which is applied in the direction of turning equipment, turning equipment, toolholder accessories, etc., to achieve the effect of avoiding wave irregularity and counteracting regenerative chatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

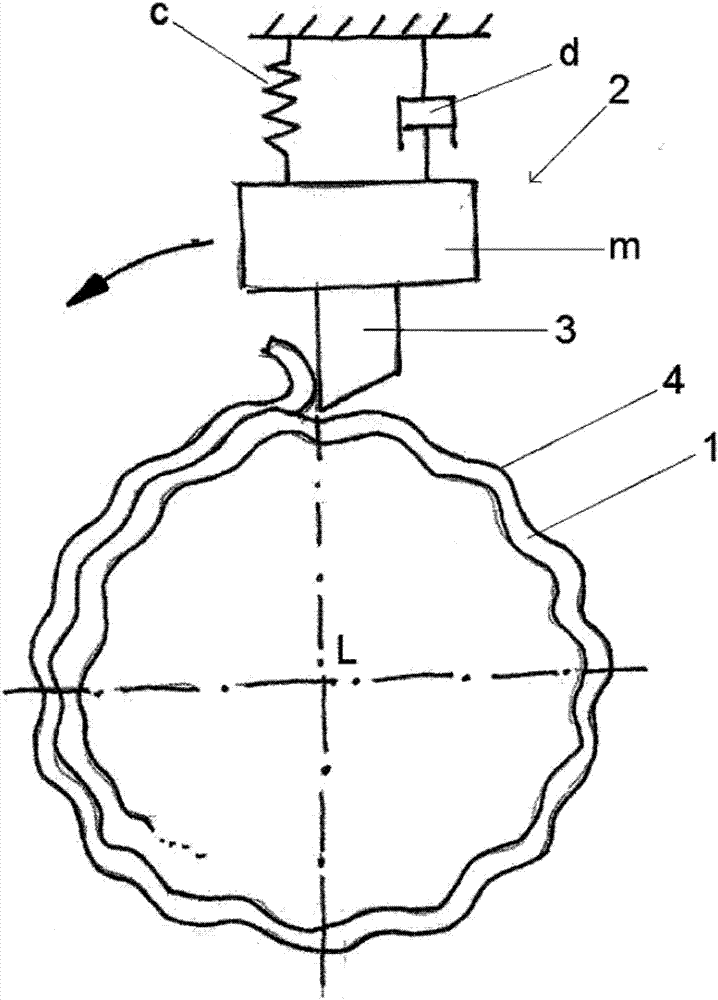

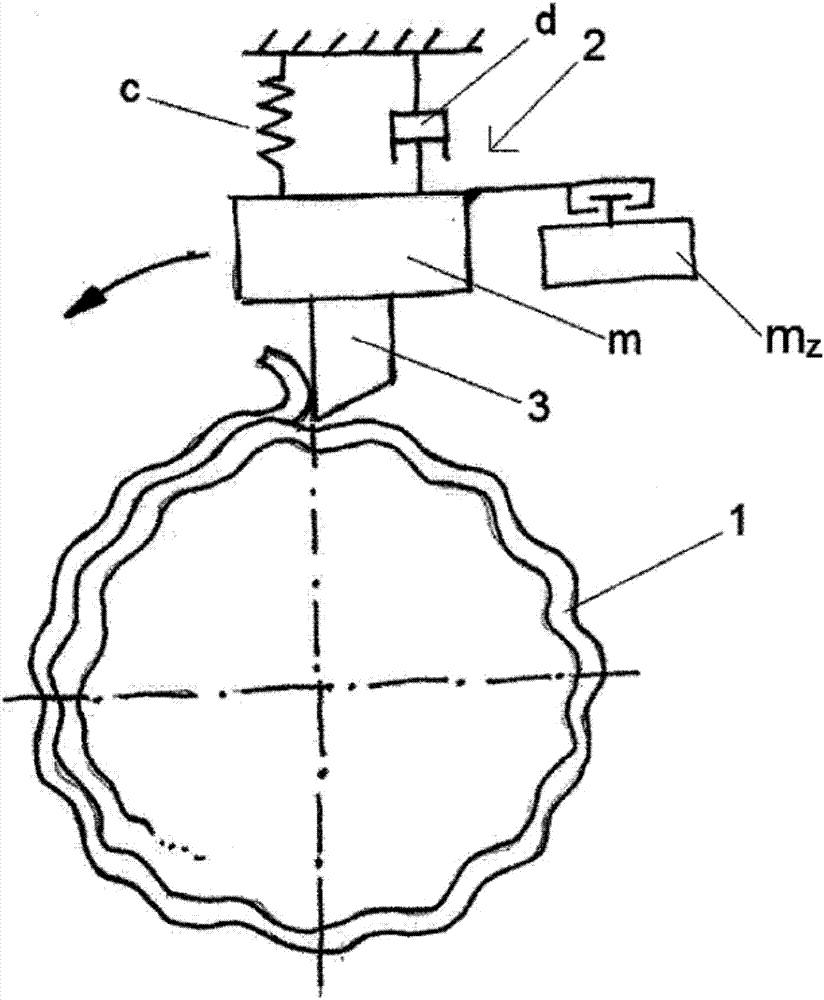

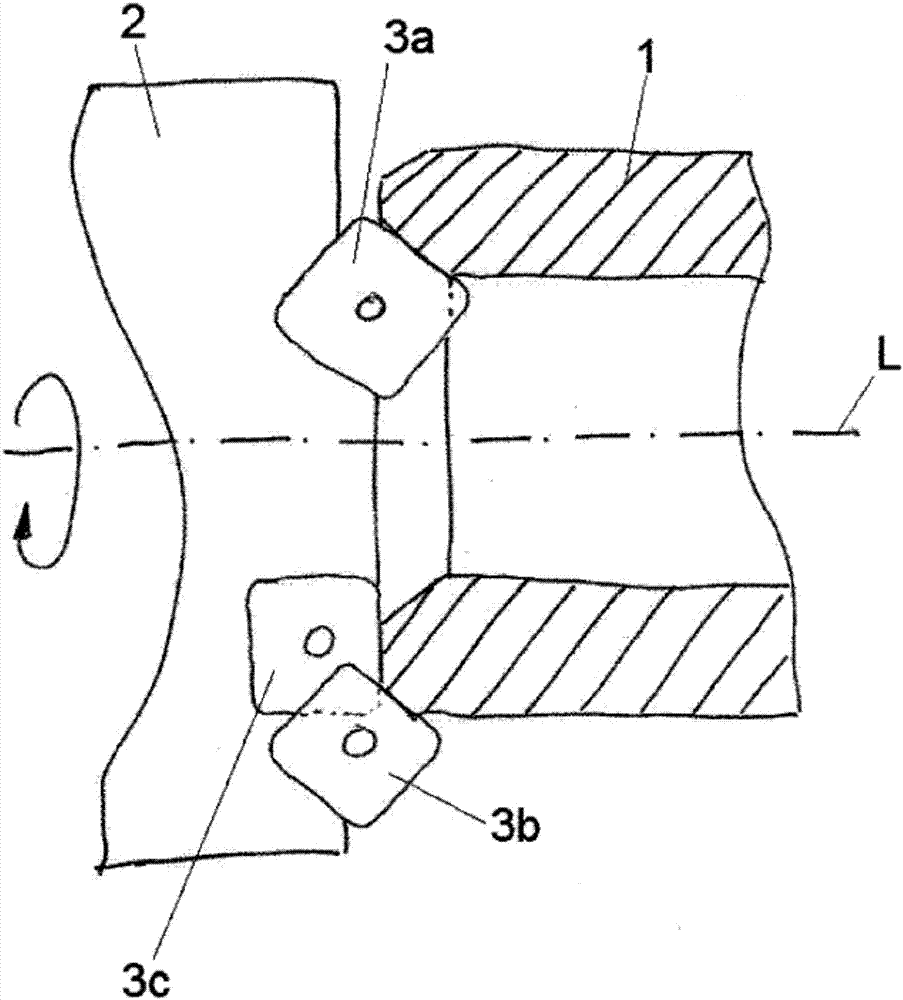

[0041] figure 1 A workpiece of substantially circular cross-section is schematically shown, for example a pipe section 1 which is substantially circular in outer cross-section. However, the workpiece can also be a solid profile or a solid and hollow profile in some parts. The workpiece is preferably made of metal, particularly preferably of steel; however, other materials are also conceivable. The pipe section 1 is processed by a tool head 2 which, in the schematic illustration, has exactly one single blade 3 . Naturally, the tool head 2 can also have two, three or a higher number of blades 3 . The tool head 2 and the pipe section 1 rotate relative to each other. In this case, the tool head 2 can be fixed in space relative to the cutting machine (not shown) and the tube can be rotated about a longitudinal axis oriented in the longitudinal direction L, or the tube section 1 can be fixed in space relative to the cutting machine , and the cutter head 2 is rotatable about the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap