Rubber sheath for automotive wiring harness

A technology for automotive wiring harnesses and rubber sheaths, which is applied to vehicle components, electrical components, circuits or fluid pipelines, etc., can solve problems such as sheaths pulling out, and achieve the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

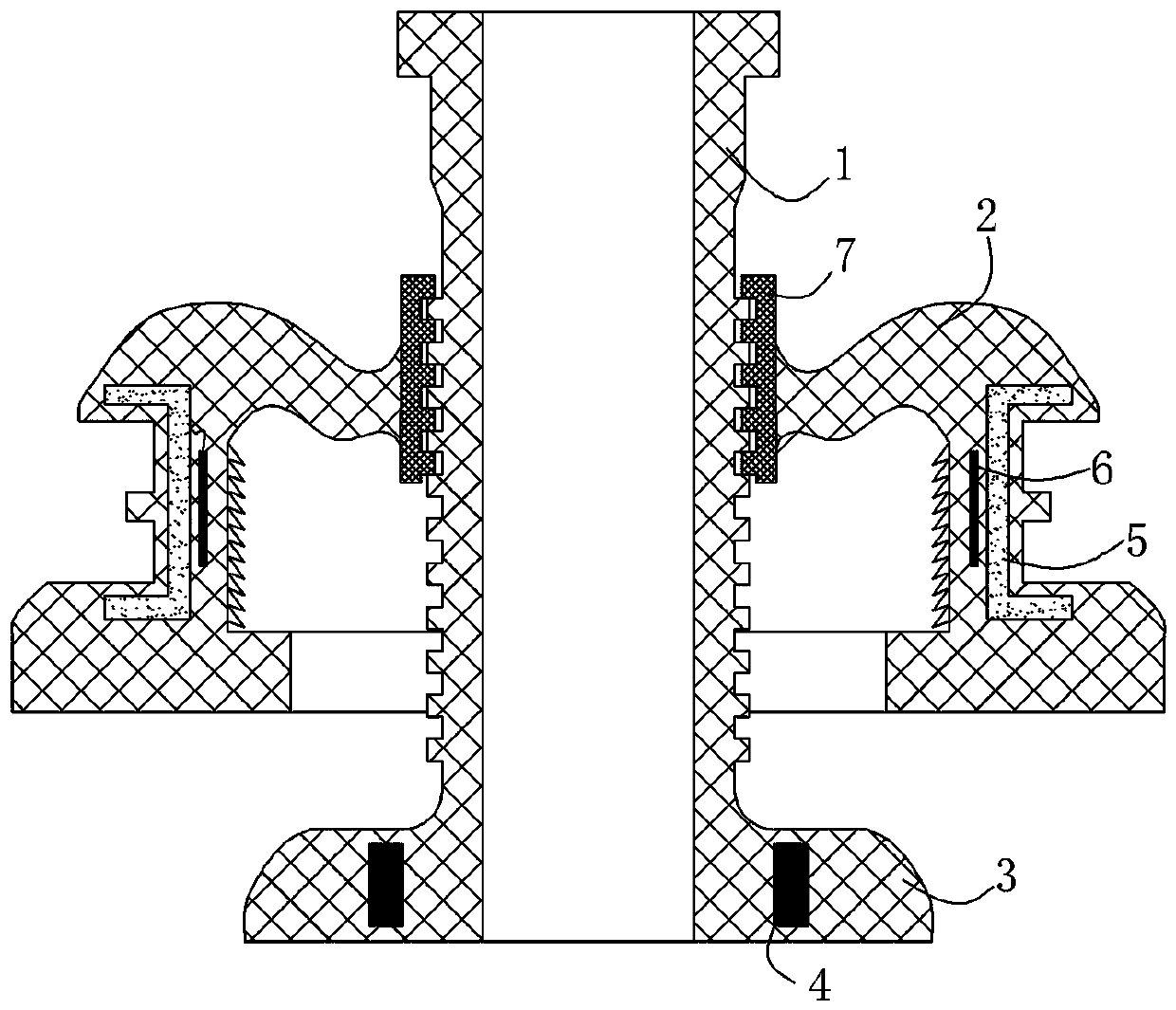

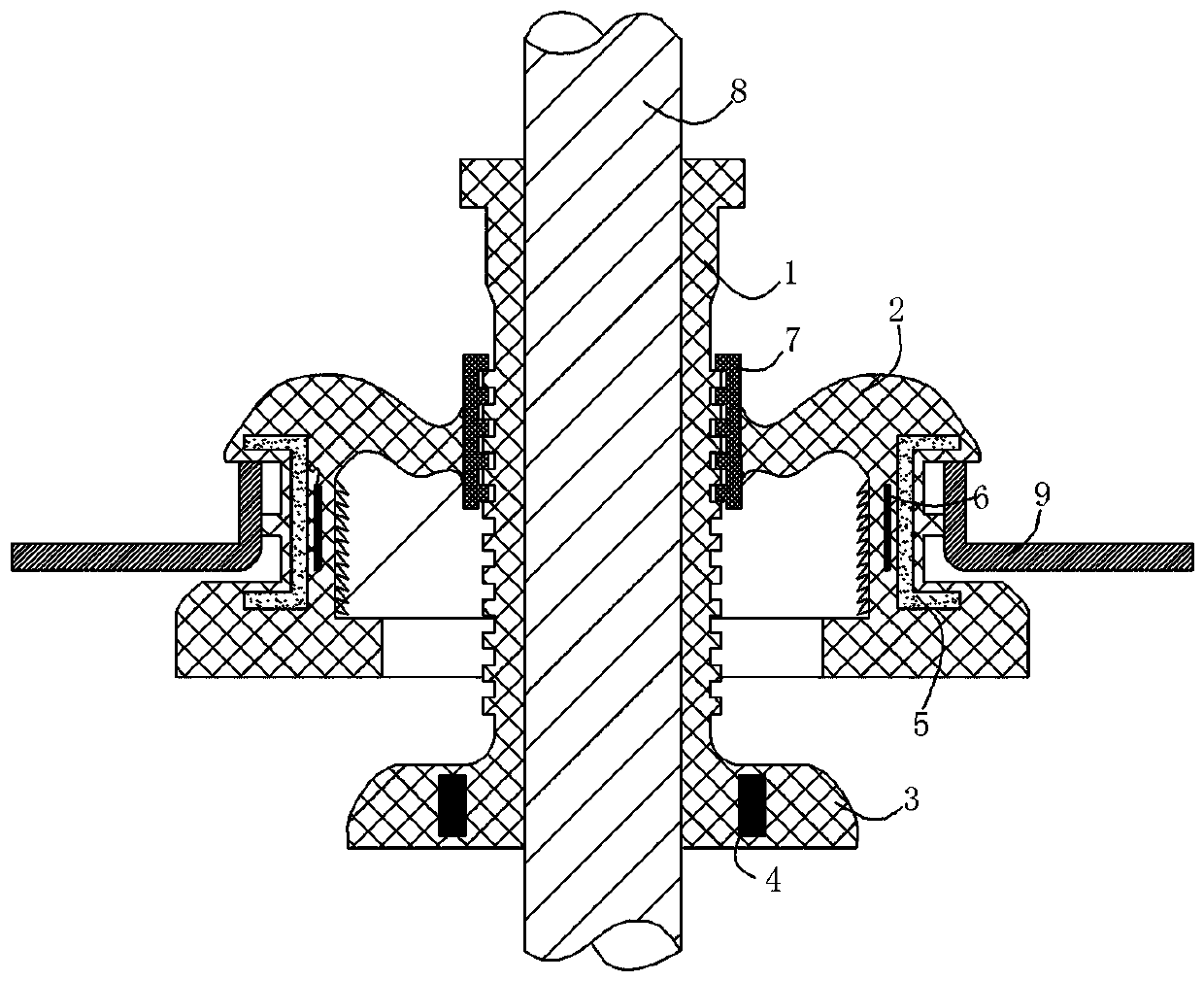

[0021] The embodiment of rubber sheath for automobile wiring harness of the present invention: as figure 1 and figure 2 As shown, the rubber sheath includes a central sheath 1 for the wiring harness 8 to pass through and a protective ring 2 connected to the sheet metal hole 9. Both the protective ring 2 and the central sheath 1 are made of rubber, and the protective ring The strength of 2 is not higher than that of the central sheath 1; the protective ring 2 is cap-shaped with a closed front end and an open rear end, and the rear section of the protective ring 2 and the outer wall of the central sheath 1 form an annular cavity. The outer wall of the rear section of the sleeve 1 is protruded with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com