Laser weakening process for seamless airbag

A laser and airbag technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting the appearance, weakening traces of the appearance of the instrument panel, etc., and achieve the effect of beautifying the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

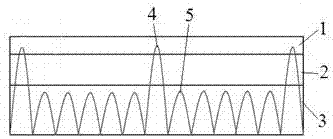

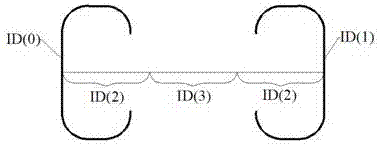

[0023] see figure 1 and figure 2 , the embodiment of the present invention includes: a seamless airbag laser weakening process, the specific steps include:

[0024] Step 1: Spray glue on one surface of body skeleton 1 on the dashboard and one surface on 3D-mesh2 respectively.

[0025] Step 2: Paste the glue-sprayed surface of body frame 1 on the dashboard and the glue-sprayed surface of 3D-mesh2.

[0026] Step 3: Put the body frame 1 on the instrument panel that has been glued with 3D-mesh in step 2 into an oven and heat at a temperature of 75~85°C.

[0027] Step 4: Spray glue on the other side of the body frame 1 on the instrument panel with 3D-mesh2 in step 3 and the surface of the skin 3 opposite to the leather side.

[0028] Step 5: Paste the glue-sprayed surface of the body frame 1 on the instrument panel with 3D-mesh2 and the glue-sprayed surface of the epidermis 3 with each other.

[0029] Step 6: Carry out vacuum adsorption on the body frame 1 on the instrument pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com