Fuel gas cock valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

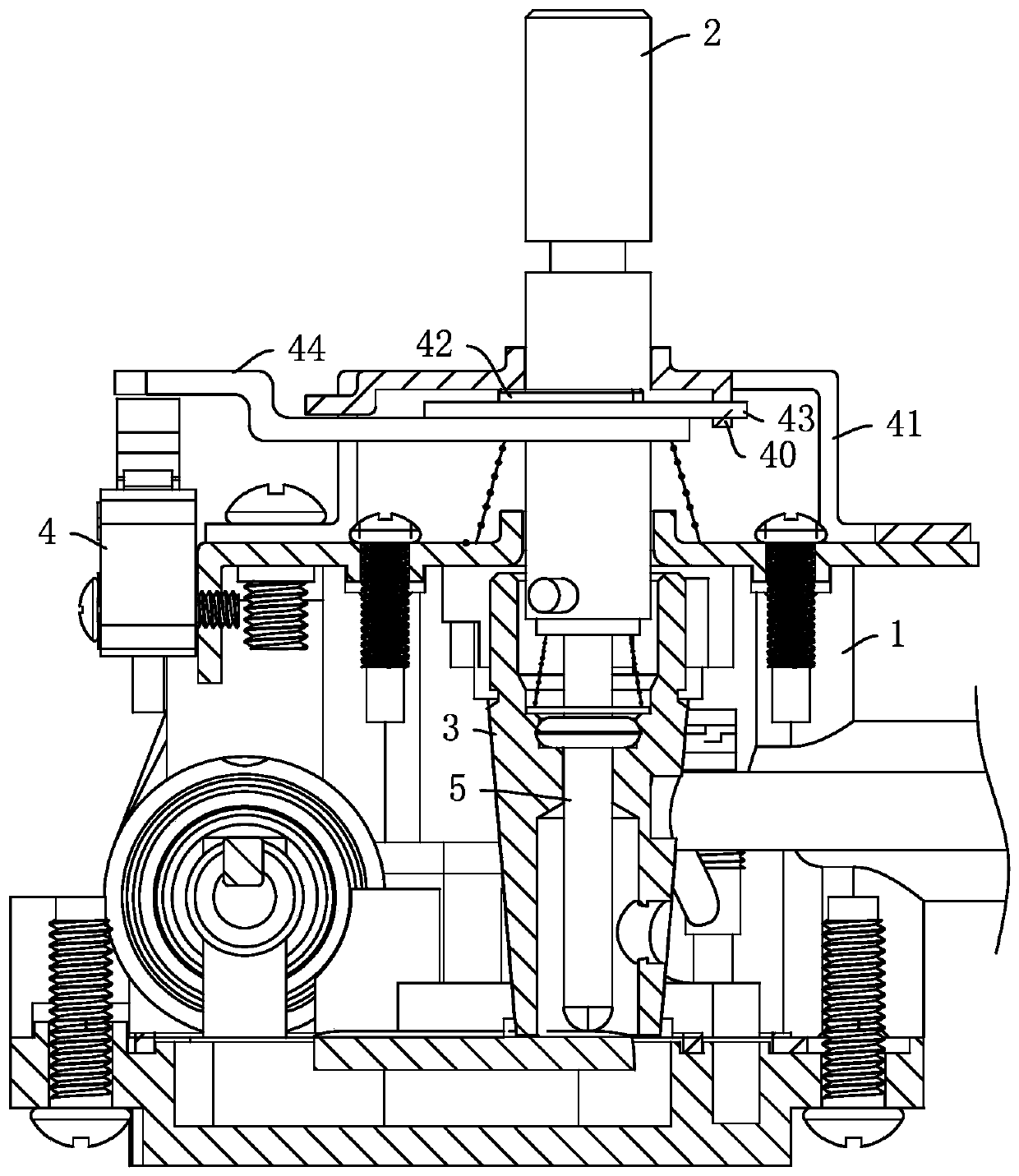

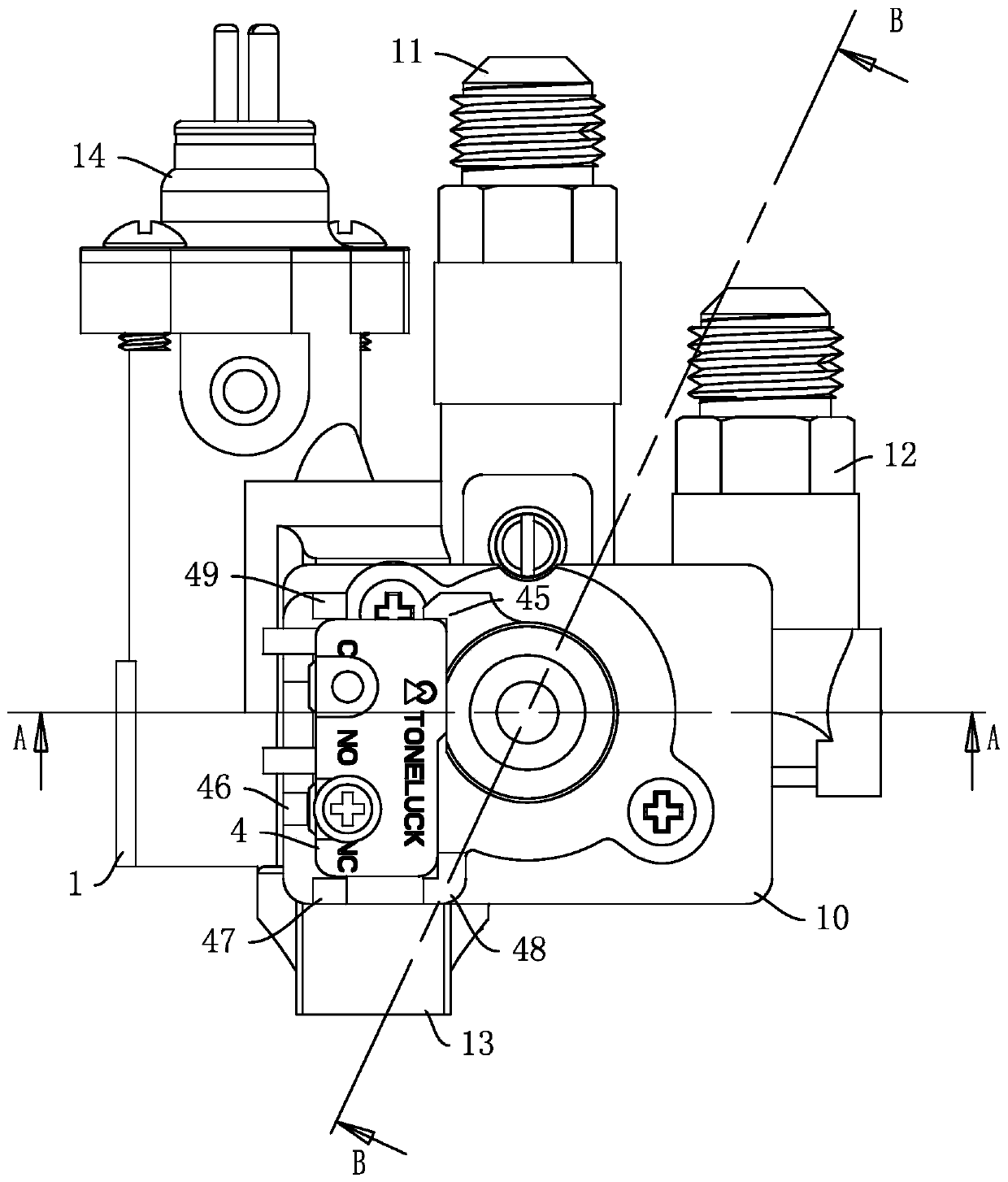

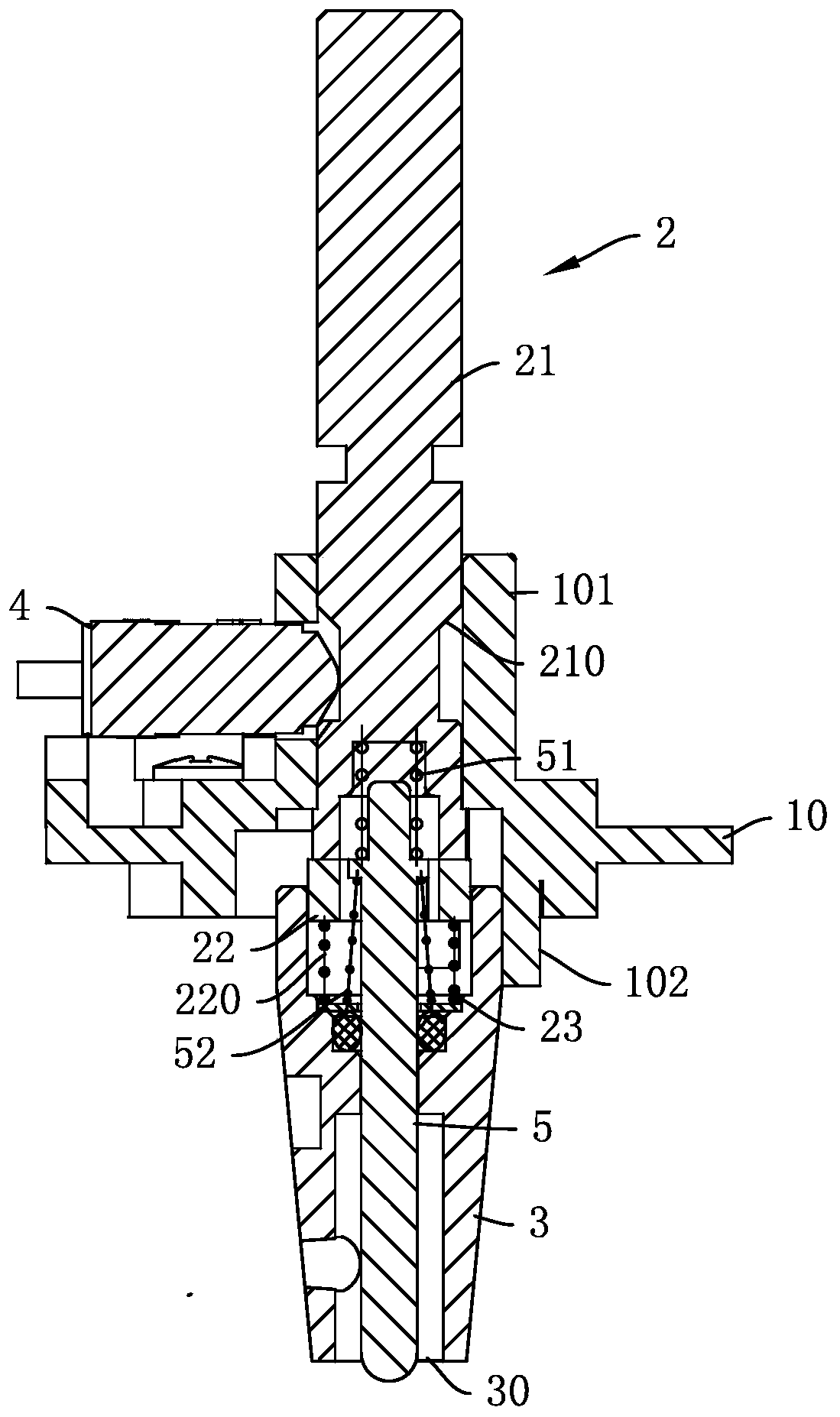

[0027] Such as Figure 2-4 As shown, a gas cock valve includes a valve body 1, a valve stem 2, a valve core 3 and a thimble 5 passing through the valve core 3. The valve body 1 has a valve core hole for assembling the valve core 3 (for simplified structure, image 3 with Figure 4 The valve body part is omitted, so the spool hole is not shown) and the cover plate 10 sealing the spool hole. The valve stem 2 extends to the position of the valve core 3 through the cover plate 10 and is connected with the thimble 5 .

[0028] Such as figure 2 As shown, the valve body 1 is provided with an air inlet 13, an inner ring air outlet 11 and an outer ring air outlet 12, and the inner ring air outlet 11, the outer ring air outlet 12 meet the side wall of the valve core hole to form an inner ring air intake mouth and outer ring air inlet (not shown in the figure). When the air inlet of the inner ring and the air inlet of the outer ring are aligned with the gas distribution hole on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com