Monomer overlarge-capacity polymer lithium ion battery and manufacturing method thereof

A lithium-ion battery and manufacturing method technology, applied in the field of lithium-ion batteries, can solve the problems of limited battery capacity, difficult to achieve high battery capacity, difficult to exceed battery capacity, etc., to achieve the effect of meeting the demand for electricity and increasing the voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

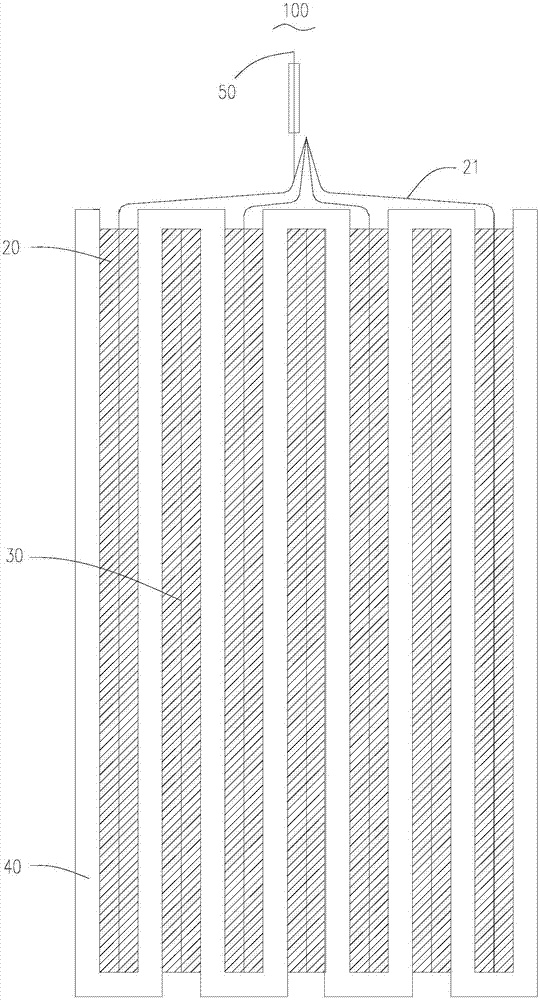

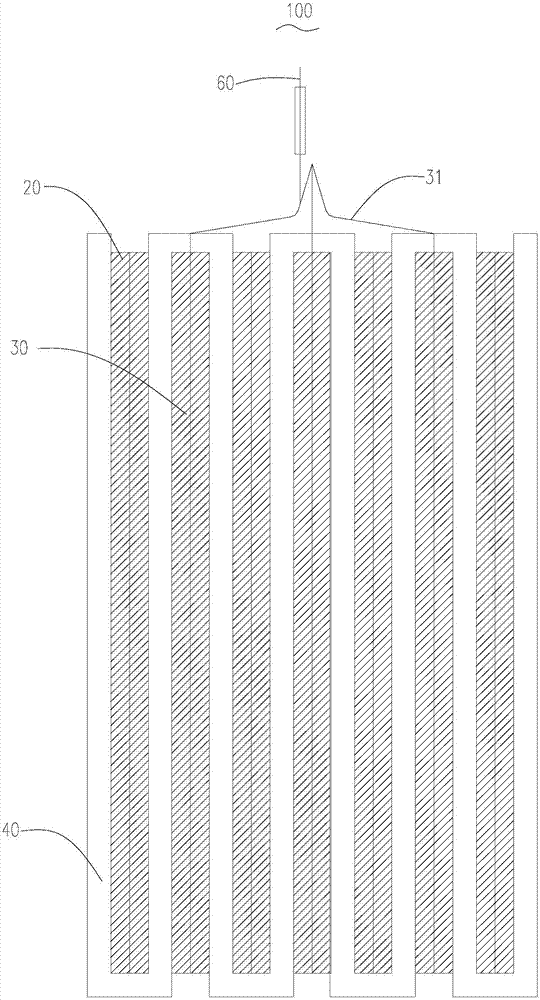

[0093] The manufacturing method of 500Ah high-capacity battery is as follows:

[0094] Step 1: Selection of the total positive tab 50 and the total negative tab 60 of the battery. Calculated according to the maximum battery output current of 1C, which is 500A, the width of the total positive tab 50 is aluminum strip, the thickness a1 is 280mm, the thickness t1 is 0.4mm, the total negative tab 60 is copper strip, the width a2 is 280mm, and the thickness t2 is 0.3mm, the conduction capacity of the aluminum strip is 6A / mm 2 , the conduction capacity of the copper strip is 8A / mm 2 , the current that the total positive tab 50 can pass is 280×0.4×6=672A, the current that the total negative tab 60 can pass is 280×0.3×8=672A, and the total positive and total negative tabs 60 of the battery meet the overcurrent requirements.

[0095] Step 2. Selection of battery size. According to the equipment processing capacity of the factory, the battery length b is set to 430mm, and the width a...

Embodiment 2

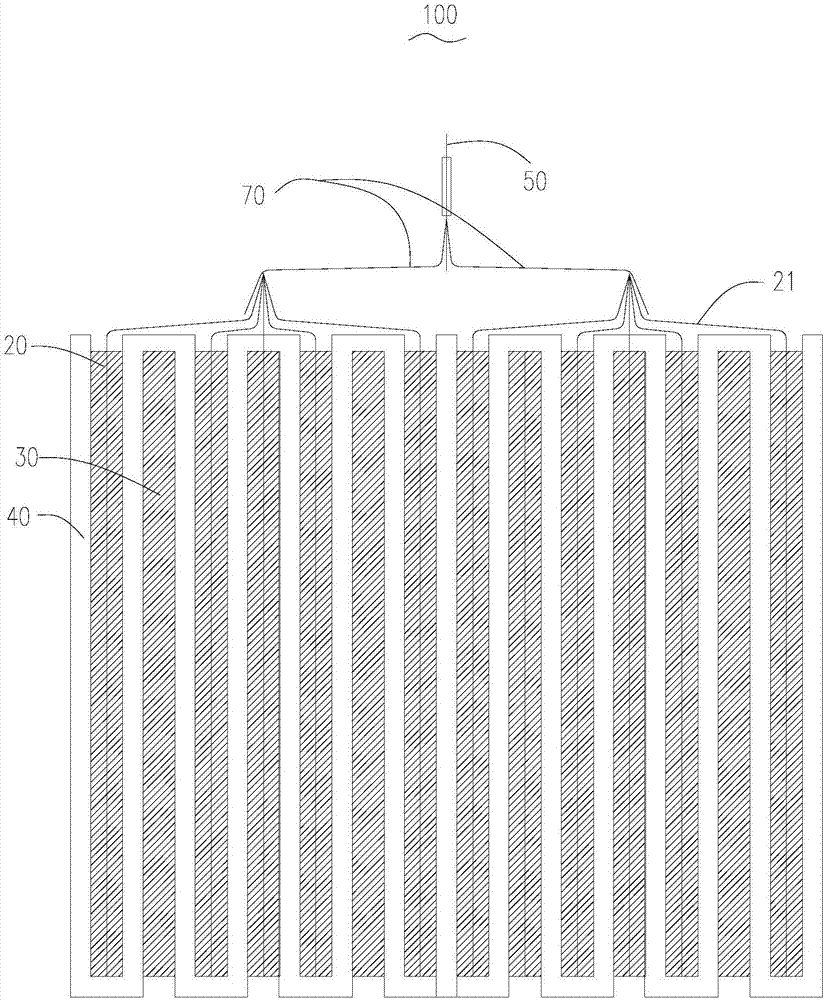

[0100] 1000Ah high-capacity battery manufacturing details are as follows:

[0101] Step 1: Selection of the total positive tab 50 and the total negative tab 60 of the battery. Calculated according to the maximum battery output current of 1C, which is 1000A, the width of the total positive tab 50 is aluminum strip, the thickness a1 is 280mm, the thickness t1 is 0.4mm, the total negative tab 60 is copper strip, the width a2 is 280mm, and the thickness t2 is 0.3mm, the conduction capacity of the aluminum strip is 6A / mm 2 , the conduction capacity of the copper strip is 8A / mm 2 , the current that can pass through the total positive tab 50 is 280×0.4×6=672A, the current that can pass through the total negative tab 60 is 280×0.3×8=672A, and the total positive and total negative tabs of the battery need two to meet the overcurrent Require.

[0102] Step 2. Selection of battery size. According to the equipment processing capacity of the factory, the battery length b is set to 430m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com