Cold-rolled super-thin CVC plate shape control method

A shape control and ultra-thin technology, applied in metal rolling, profile control, metal rolling, etc., can solve the problems of frequent broken belt accidents, hard to control the shape of the shape, and large wave shape, etc., to achieve good shape and improve The qualified rate of plate shape and the effect of plate shape improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

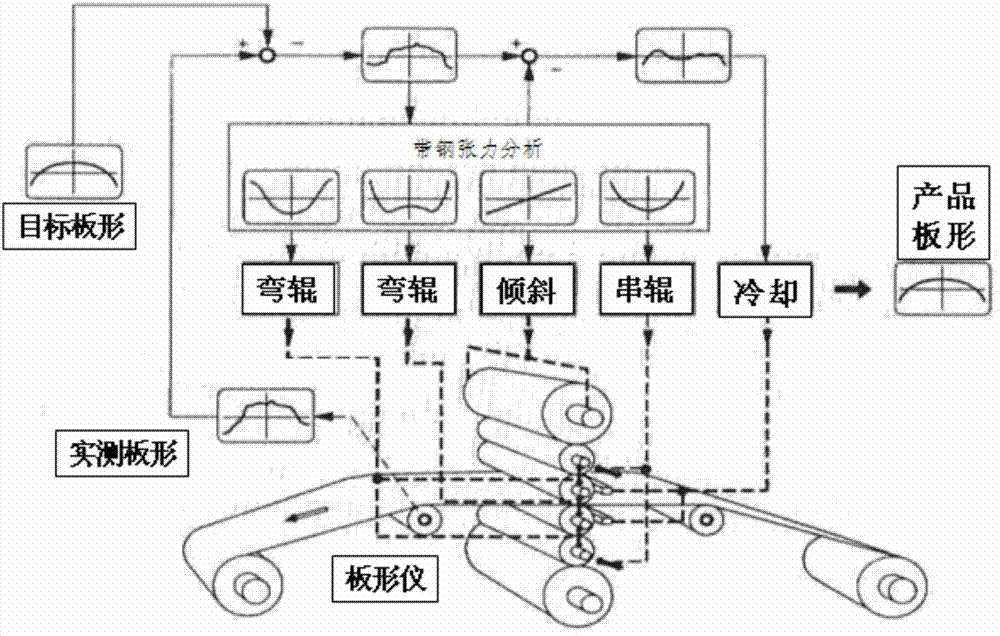

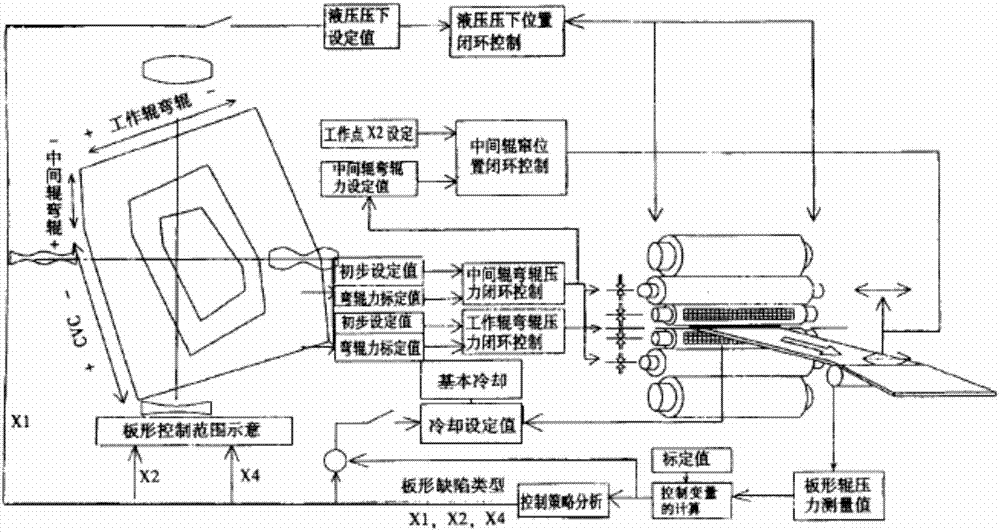

Method used

Image

Examples

Embodiment Construction

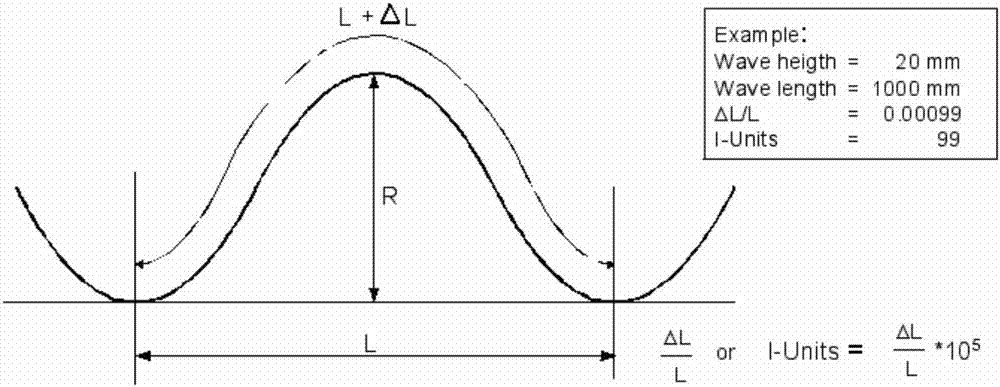

[0021] In the present invention, relevant terms are explained as follows:

[0022] Plate shape: Intuitively speaking, it refers to the degree of warpage of the plate, and its essence refers to the distribution of internal residual stress. The plate shape includes the vertical and horizontal dimensions of the strip. Longitudinal usually refers to straightness (wave shape), that is, the degree of flatness along the length of the strip. The transverse direction refers to the cross-sectional shape of the plate, that is, the thickness distribution in the width direction of the plate, including the convexity of the plate, thinning of the edge, etc. Among them, the convexity of the plate is the representative index of the transverse plate shape.

[0023] Flatness of plate: The straightness of plate and strip refers to the distribution of internal residual stress. During the deformation process of plate and strip rolling, each narrow part of the good plate shape along the width of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com