Method for judging generation of edge waves of over-temper mill roller

A technology for tempering mills and rolls, which is applied in the field of edge wave generation control of the tempering mill rolls. It can solve the problems that the edge waves cannot be improved or eliminated, and the leveling quality is reduced, so as to improve production efficiency and reduce edge waves. Produce and guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

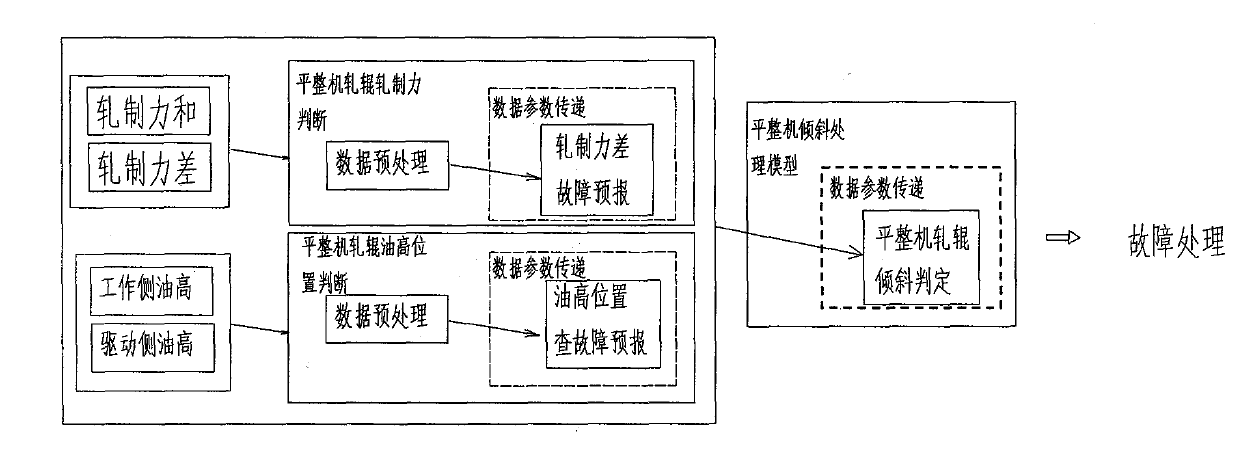

[0026] Such as figure 1 As shown, the present invention provides a method that can accurately calculate the inclination of the temper mill rolls to judge the generation of side waves, including the following steps:

[0027] Step 1: Data collection and preprocessing

[0028] Real-time collection of rolling force F on the driving side and the operating side of the roll WS * , F DS * And the oil height position on the driving side and the operating side of the roll is Y WS * , Y DS * .

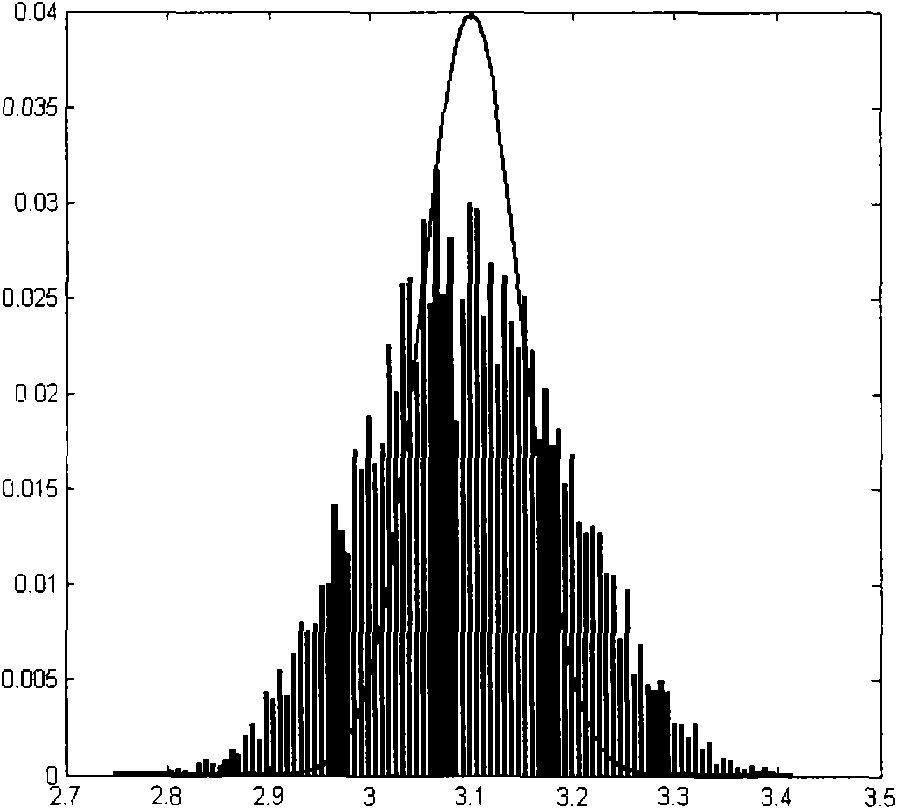

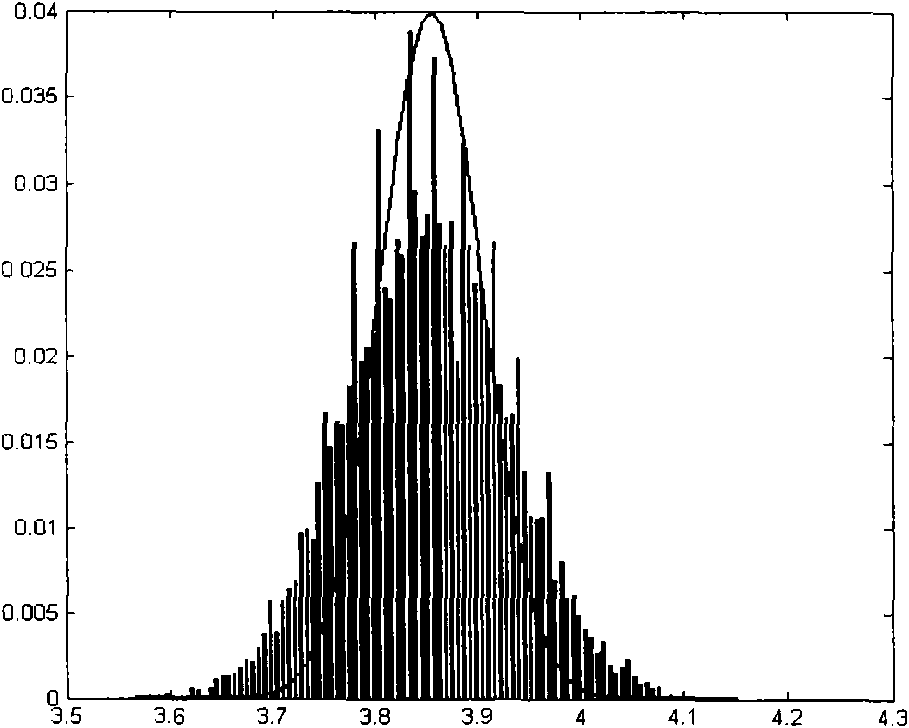

[0029] In order to remove the influence of roller eccentricity and bearing vibration, the above data is processed by the following moving average filter:

[0030] F ws ( k ) = Σ j = 0 N - 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com