Underground communication optical cable trench

An underground communication and optical cable technology, applied in optical fiber/cable installation, optics, light guide, etc., can solve problems such as difficulty in meeting the laying requirements of large-capacity communication cables and narrow inner diameter of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The core of the present invention is to provide an underground communication optical cable trench, which can accommodate more communication cables, is convenient for operators to enter and exit, and can meet the requirements of later reconstruction and expansion.

[0030] In order to enable those skilled in the art to better understand the technical solution of the present invention, the underground communication optical cable trench of the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

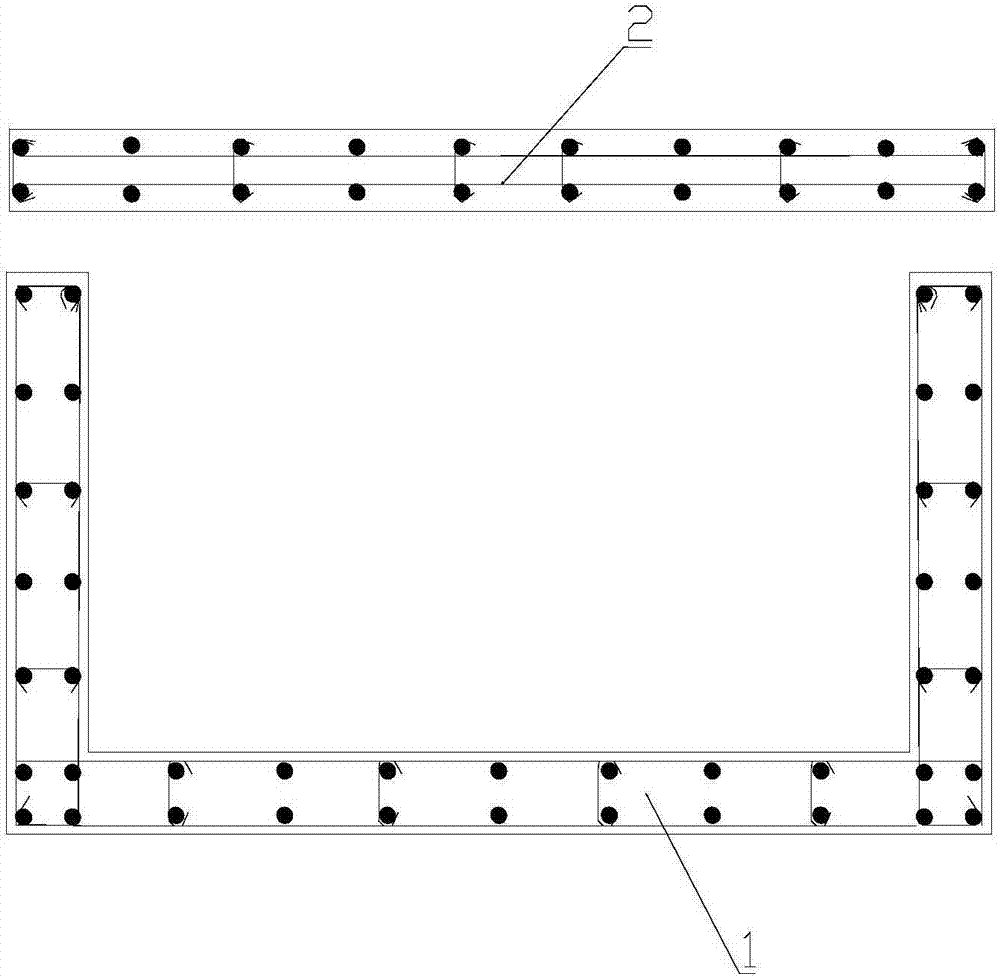

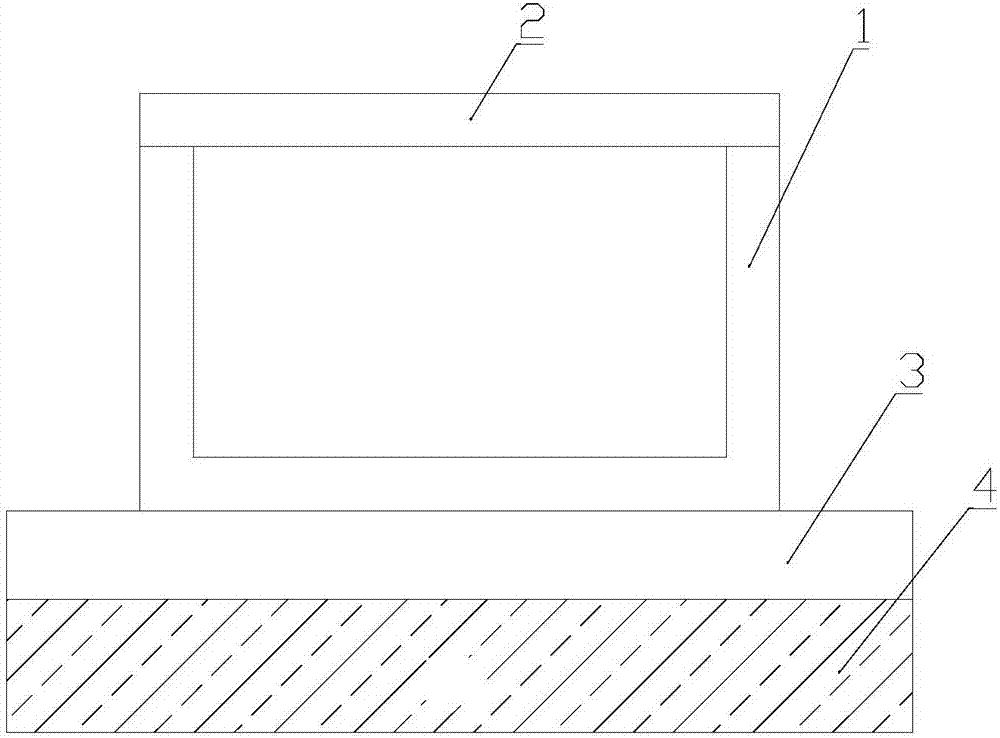

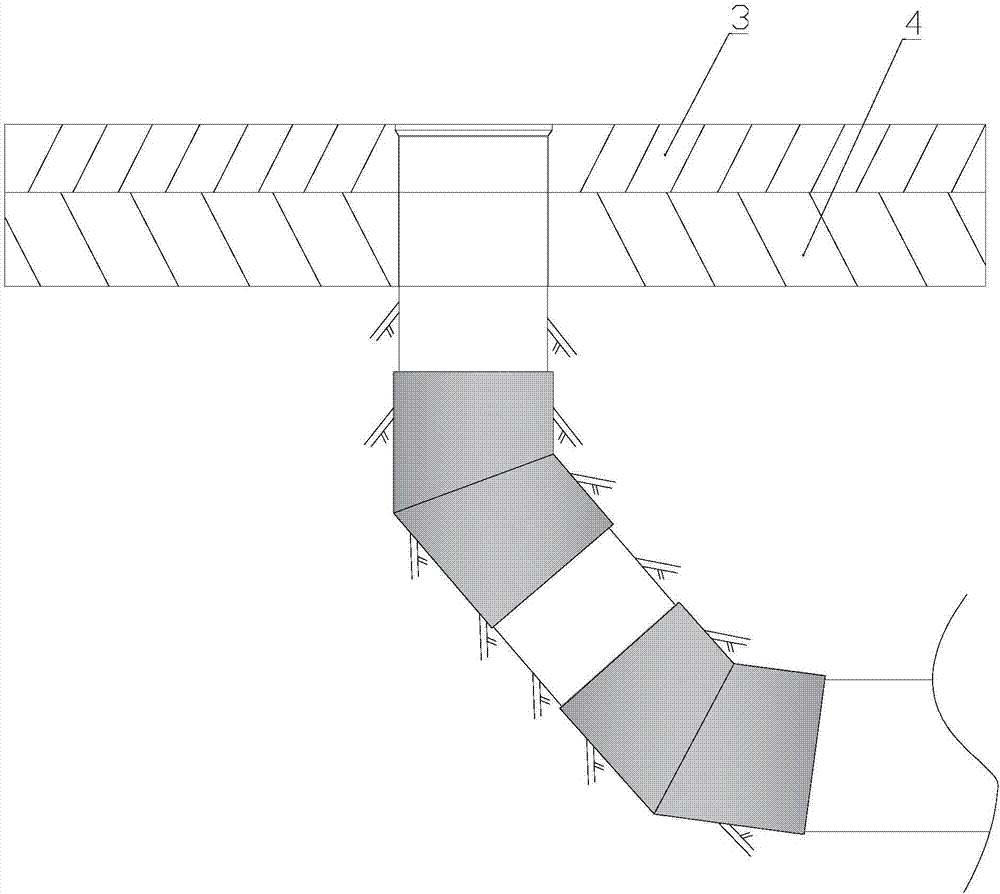

[0031] The invention discloses an underground communication optical cable trench, which is buried underground and is an underground channel for accommodating and distributing communication optical cables, including a reinforced concrete prefabricated pipe groove 1 and a cover plate 2, such as figure 1 As shown, it is a relative position relationship diagram of reinforced concrete prefabricated pipe g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com