A skeleton type hybrid optical cable

A skeleton type, skeleton technology, applied in the field of optical communication transmission, can solve the problems of the production equipment skeleton retracting and unwinding rack being bulky and bulky, affecting the stress state of the optical fiber ribbon matrix edge fiber, affecting the optical cable production efficiency, etc., and achieving flexible and convenient branch connection. , to ensure the effect of optical fiber transmission performance, production process and equipment simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

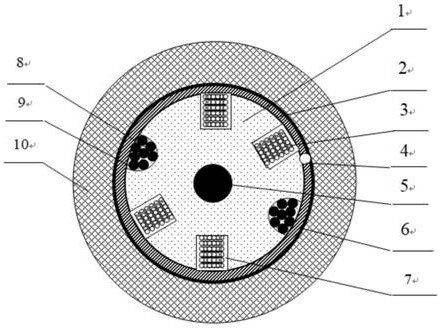

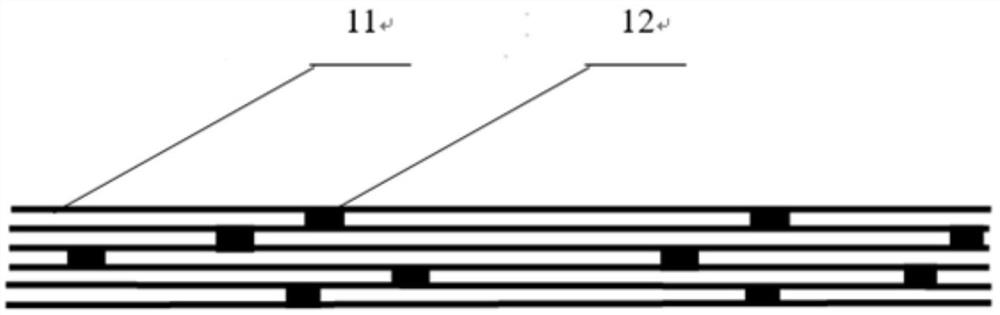

[0018] An example of the present invention is Figure 1-3 As shown, it includes a skeletal cable core and an outer sheath 10, the skeletal cable core includes a skeleton 1, and a reinforcing member 5 is installed in the middle of the skeleton, and the reinforcing member is steel wire or aramid yarn There are 6 skeleton grooves extending in the axial direction at intervals in the circumferential direction of the skeleton, of which 4 skeleton grooves have a rectangular radial cross-section, and the optical fiber ribbon is laid in the rectangular skeleton groove 7, and the radial cross-section of the 2 skeleton grooves is a superior arc Optical fiber is laid in the superior arc-shaped skeleton groove 9; the rectangular skeleton groove and the superior arc-shaped skeleton groove are distributed symmetrically along the circumference; The optical f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com