Bucket tooth used for high-frequency breaking hammer

A technology of breaking hammer and bucket teeth, which is applied in the field of construction machinery, can solve the problems of easy generation of gaps, long time consumption, and easy displacement of tooth seats, etc., to achieve the effects of reducing contact area, improving work efficiency, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

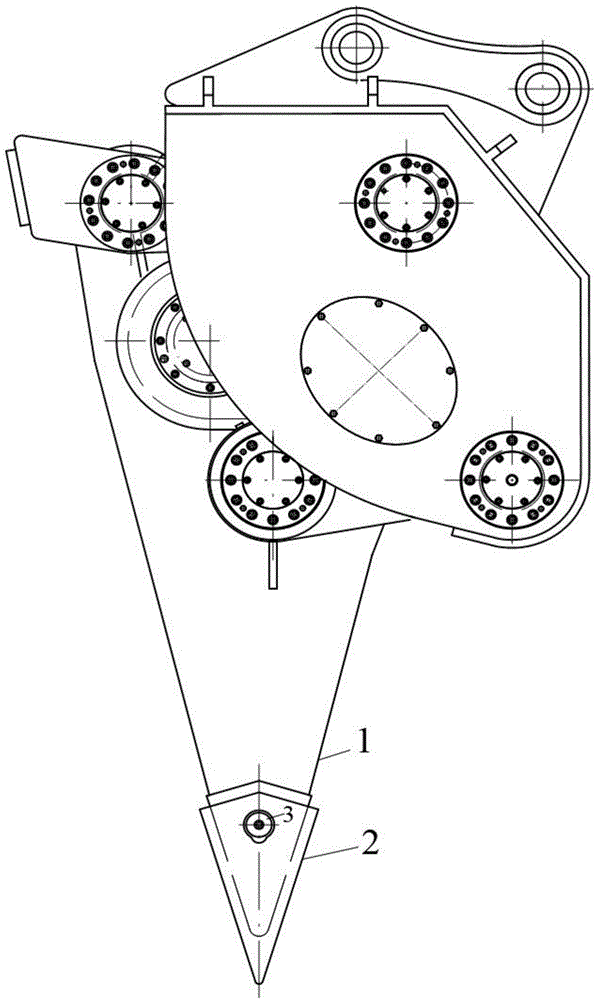

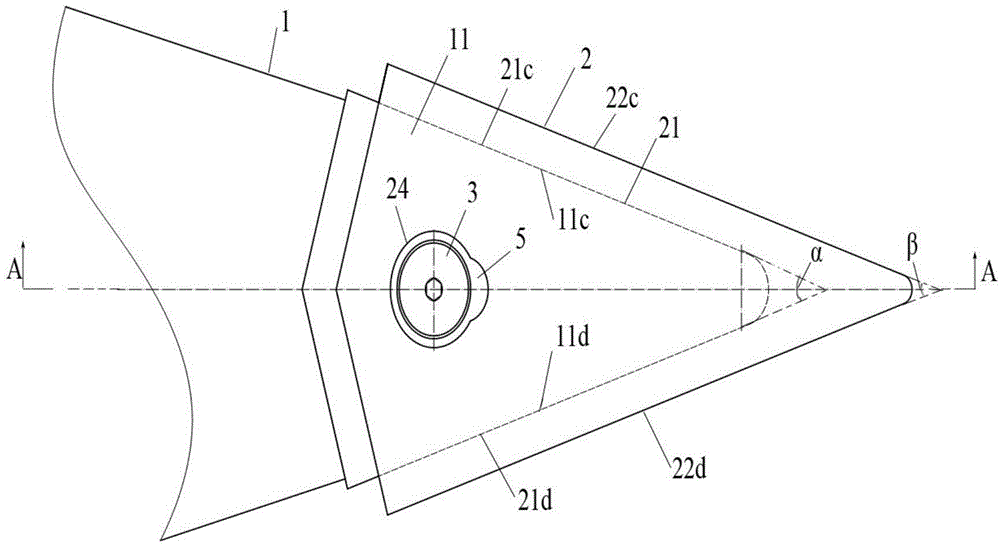

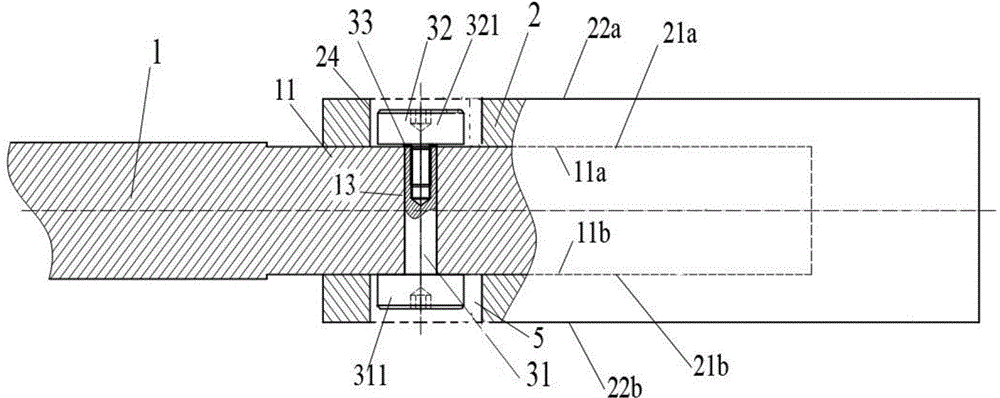

[0029] figure 1 It is a schematic diagram showing the structure of bucket teeth installed in a high-frequency breaker according to the present invention. figure 2 A schematic diagram showing the structure of a bucket tooth for a high-frequency breaker according to an embodiment of the present invention. image 3 for figure 2 The sectional view of the bucket teeth along the line A-A.

[0030] Such as Figure 1 to Figure 3 As shown, in this embodiment, the bucket tooth used for the high-frequency breaker includes a tooth seat 1, a tooth body 2, and a connecting piece 3 for connecting the tooth seat and the tooth body. The tooth holder 1 has an insertion portion 11 that can be inserted into the tooth body. The insertion portion 11 is plate-shaped, has two plate surfaces 11a, 11b parallel to each other, and two load-bearing slopes 11c, 11d that intersect at an acute angle α. The intersection of the slopes 11c and 11d is a smooth transition, and the acute angle α of the inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com