A kind of logistics conveying separation system

A separation system and logistics technology, applied in the field of logistics, can solve the problems of insufficient mobility and low work efficiency, and achieve the effects of initial speed and interval time, simple structure and strong adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following specific examples illustrate the implementation of the present invention. Those familiar with the technology can easily understand the other advantages and effects of the present invention from the content disclosed in this specification.

[0023] The present invention will be further explained below in conjunction with the drawings and embodiments:

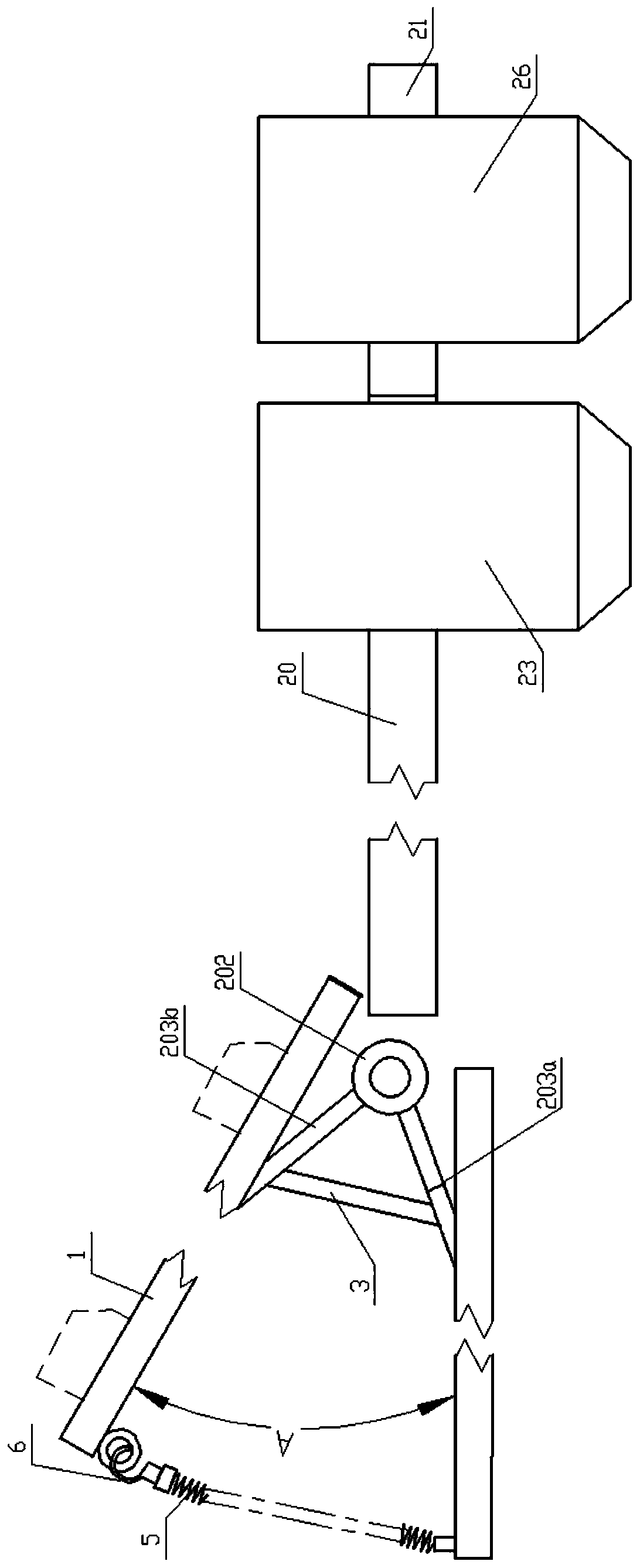

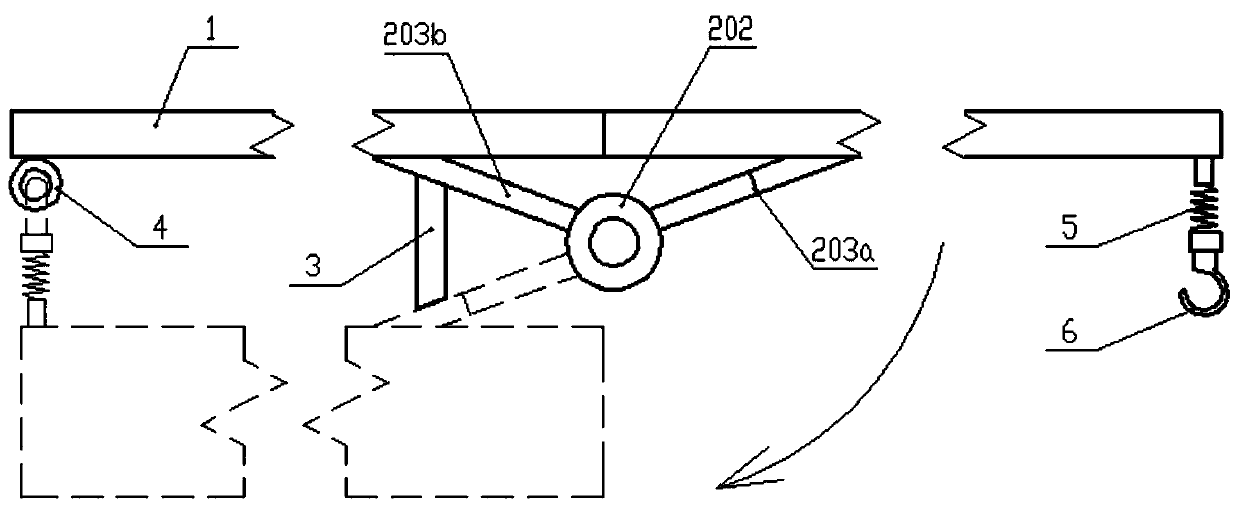

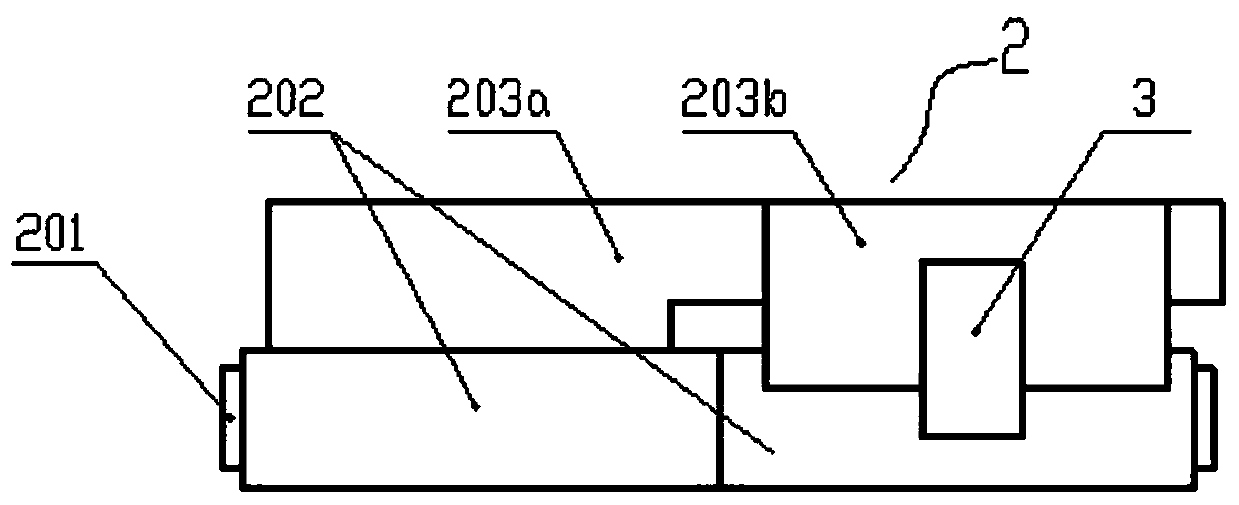

[0024] Such as figure 1 As shown in —4, a logistics conveying and separating system includes a conveying device and an automatic screening device; the conveying device includes two plates 1, and the two plates 1 are connected by a loose leaf 2; the loose leaf 2 includes a hinge shaft 201, the hinge pipe 202 and the connecting piece 203 (including the first connecting piece 203a and the second connecting piece 203b), the hinge pipe 202 is sleeved on the hinge shaft 201 in series, and each section of the hinge pipe 202 is fixedly connected with a connection Sheet 203, wherein the first connecting sheet 203a includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com