Garment steamer nozzle capable of controlling air outlet range

A technology of a garment steamer and a spray head, which is applied in the field of garment steamers, can solve the problems of small steam volume, time-consuming and laborious, and unsatisfactory effects of the steamer, and achieve the effect of stable movement direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

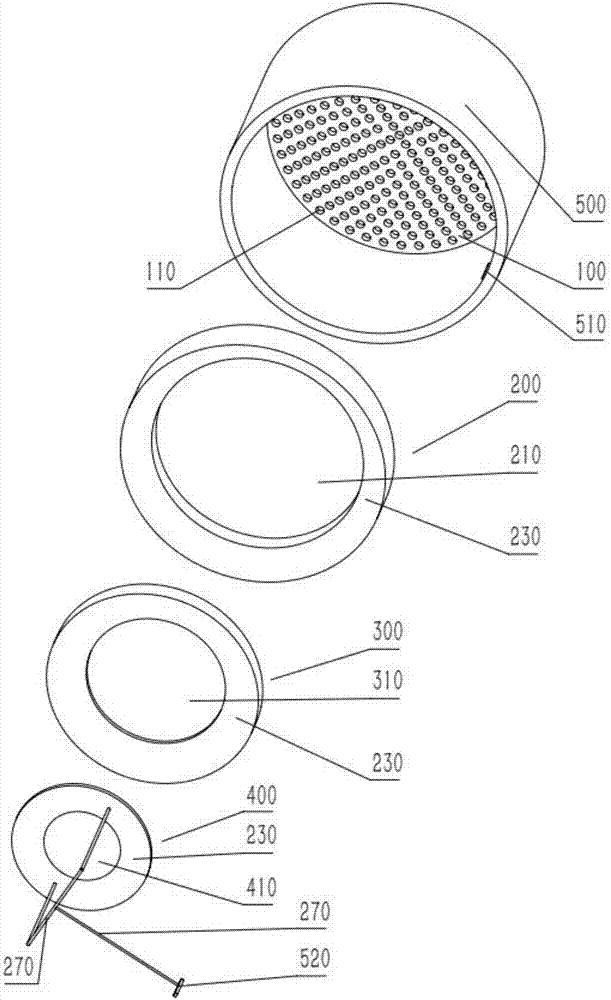

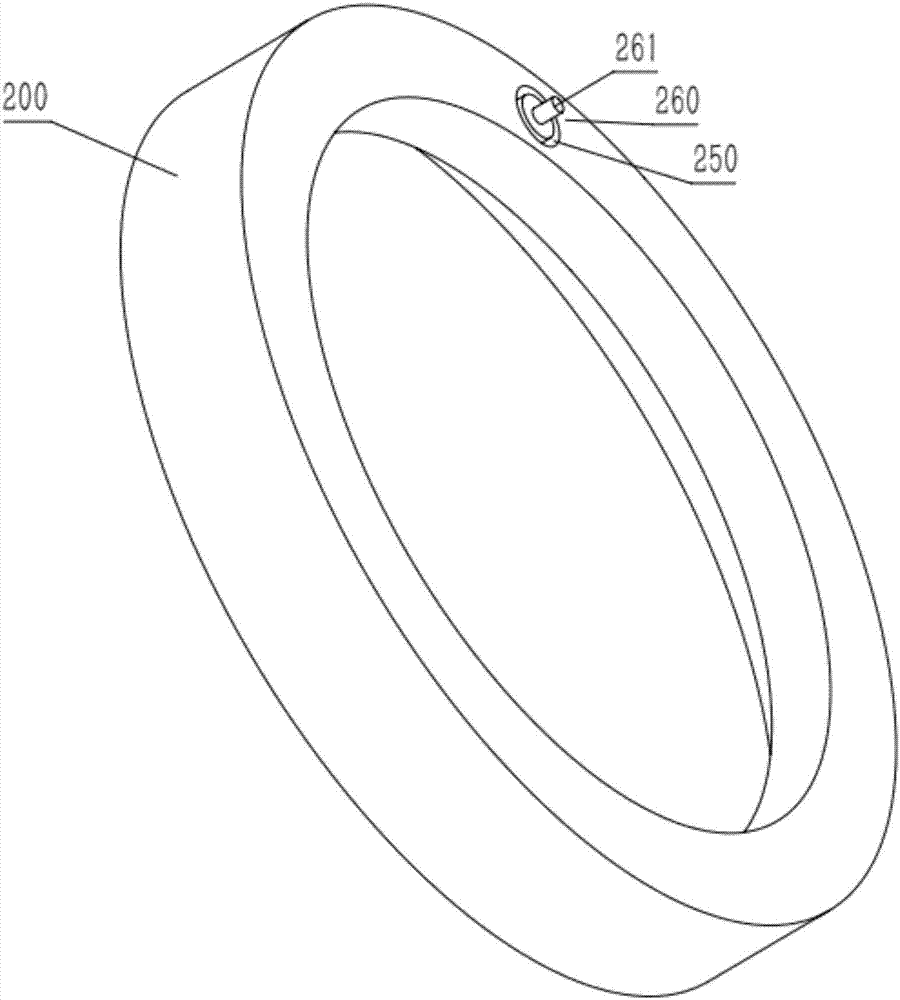

[0034] A spray head of a garment steamer capable of controlling the air outlet range, comprising: an air outlet plate 100, on which air outlet holes 110 are uniformly arranged; Plate 300 and the third moving plate 400, the diameter of the first moving plate 200 is equal to the gas outlet plate 100, the center of the first moving plate 200 is provided with a first through hole 210, the second moving plate 300 The diameter is equal to the first through hole 210, the second through hole 310 is opened in the center of the second moving plate 300, the diameter of the third moving plate 400 is equal to the second through hole 310, and the second through hole 310 is opened in the center of the second moving plate 300. The center of the three movable plates 400 is provided with a third through hole 410; the housing 500, one end of which accommodates the air outlet plate 100, and the control panel is arranged on the side of the air outlet plate 100 inside the housing 500;

[0035] Wher...

Embodiment 2

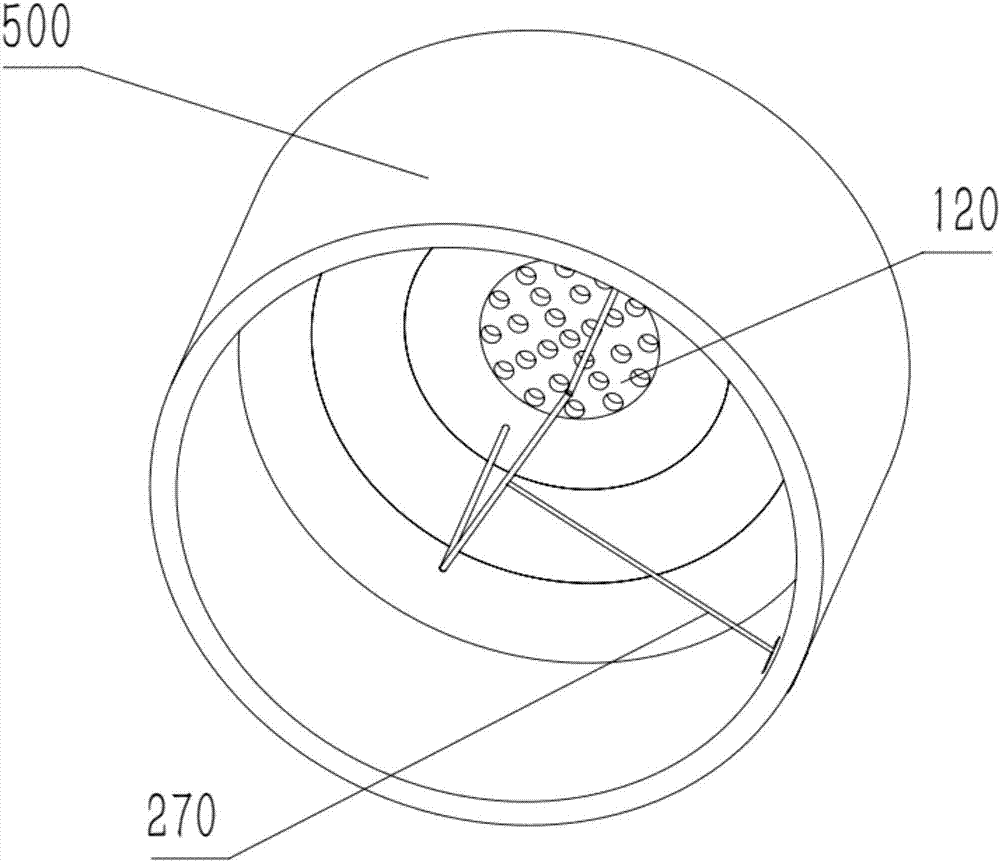

[0039] In this embodiment, the control of the moving plate is directly through manual switching, and the second ends 230 of the first moving plate, the second moving plate and the third moving plate are provided with a connecting rod 270 . The shell 500 is provided with a long hole 510 , a sliding switch 520 is slidably disposed on the long hole 510 , and the sliding switch 520 is fixedly connected with the connecting rod 270 . The sliding switch 520 has an interference fit with the elongated hole 510 , and the covered area of the sliding switch 520 is larger than the elongated through hole, so as to prevent steam from escaping through the sliding switch 520 . The position of the moving plate can be changed by manually manually toggling the slide switch 520 .

[0040] The center of the air outlet plate 100 is a detachable sub-plate 120 , and the diameter of the sub-plate 120 is equal to that of the third through hole 410 . The diameter of the third through hole 410 is 0.2-0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com