A rotatable electromagnetic railgun shell

A technology for electromagnetic railguns and shells, applied in the field of electromagnetic launch, can solve the problems of swinging or flipping, affecting the range, and large air resistance, and achieve the effects of high shooting accuracy, stable movement direction, and long range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

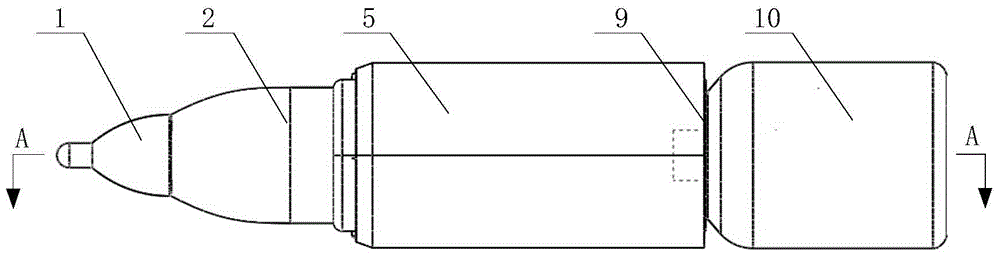

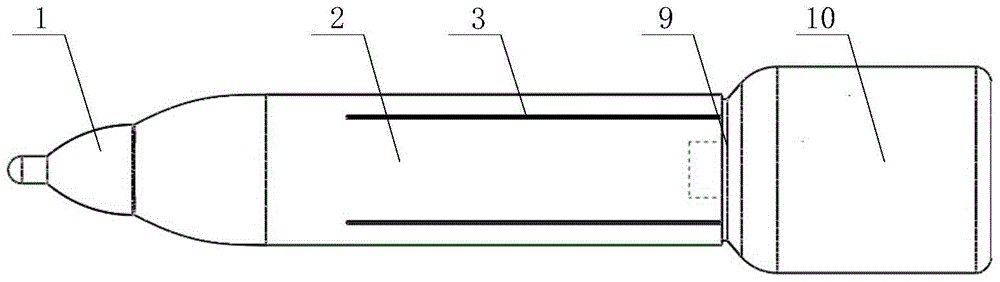

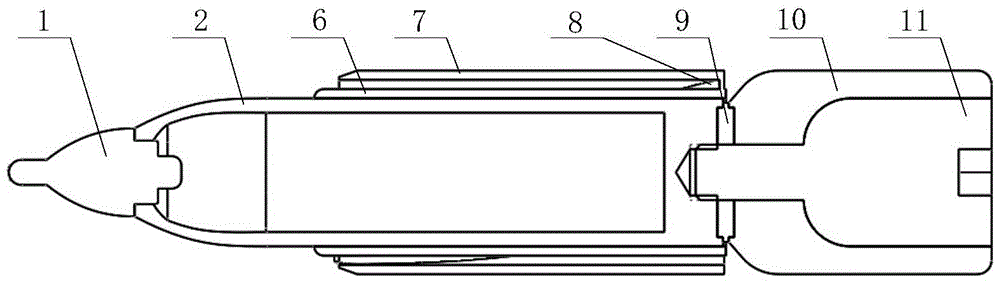

[0013] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 In the schematic diagram of the present invention shown, the outer surface of the fuze 1 rear portion is provided with threads, and the front end of the projectile body 2 is provided with a groove, and an internal thread is provided in the groove, and the fuze and the projectile body are connected by threads. The exterior of the fuze and projectile are streamlined. A T-shaped groove 3 is arranged on the outer wall of the body, and a T-shaped plate 4 is inserted into the T-shaped groove on the outer wall of the body. The T-shaped plate is fixed on the inner wall of the inner plate 6 of the rotating power shell 5 . The rotating power shell is sleeved on the outside of the projectile. The rotating power shell includes an inner plate 6, an outer plate 7 and blades 8. The inner plate and the outer plate of the rotating power shell are both cylindrical shells with openings at both ends. The inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com