Asphalt barrel taking equipment with automatic start-stop device and asphalt barrel taking method

An automatic start-stop, asphalt technology, applied in packaging, packaging recycling, transportation and packaging, etc., can solve the problems of slow efficiency and high labor intensity, and achieve the effect of ensuring no damage, reducing labor intensity and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

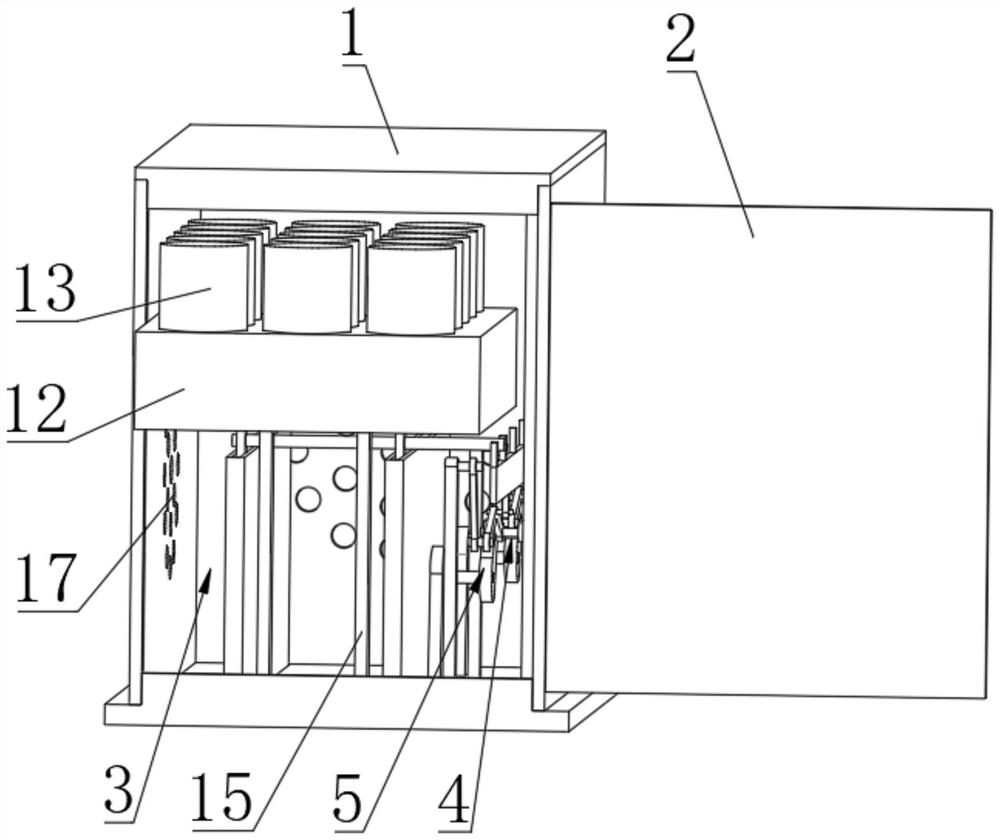

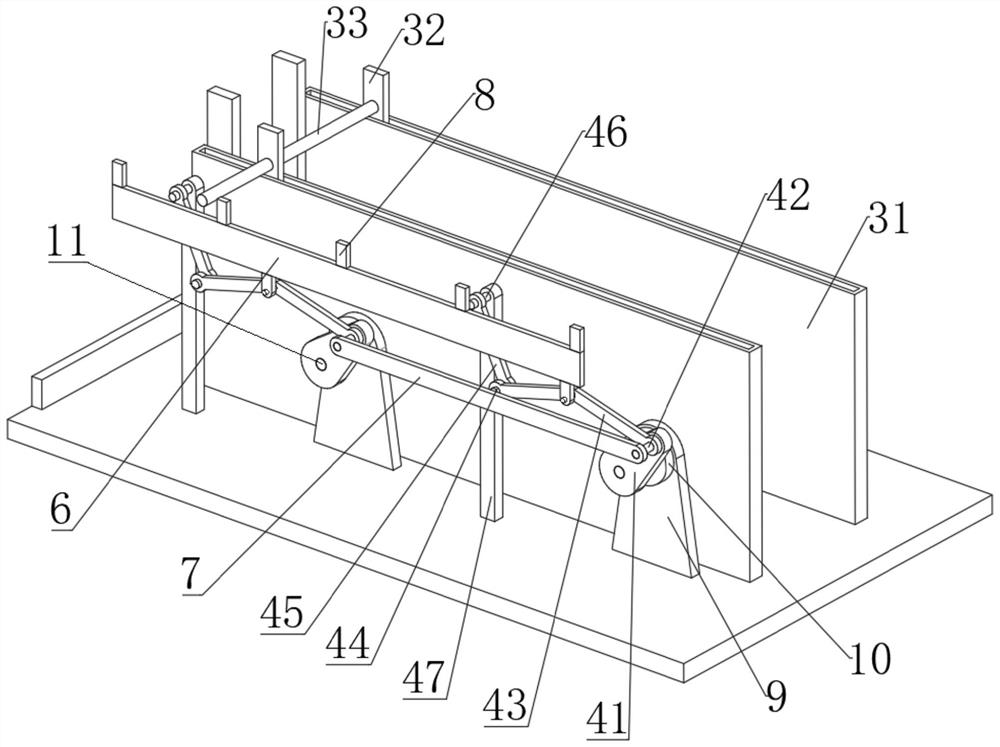

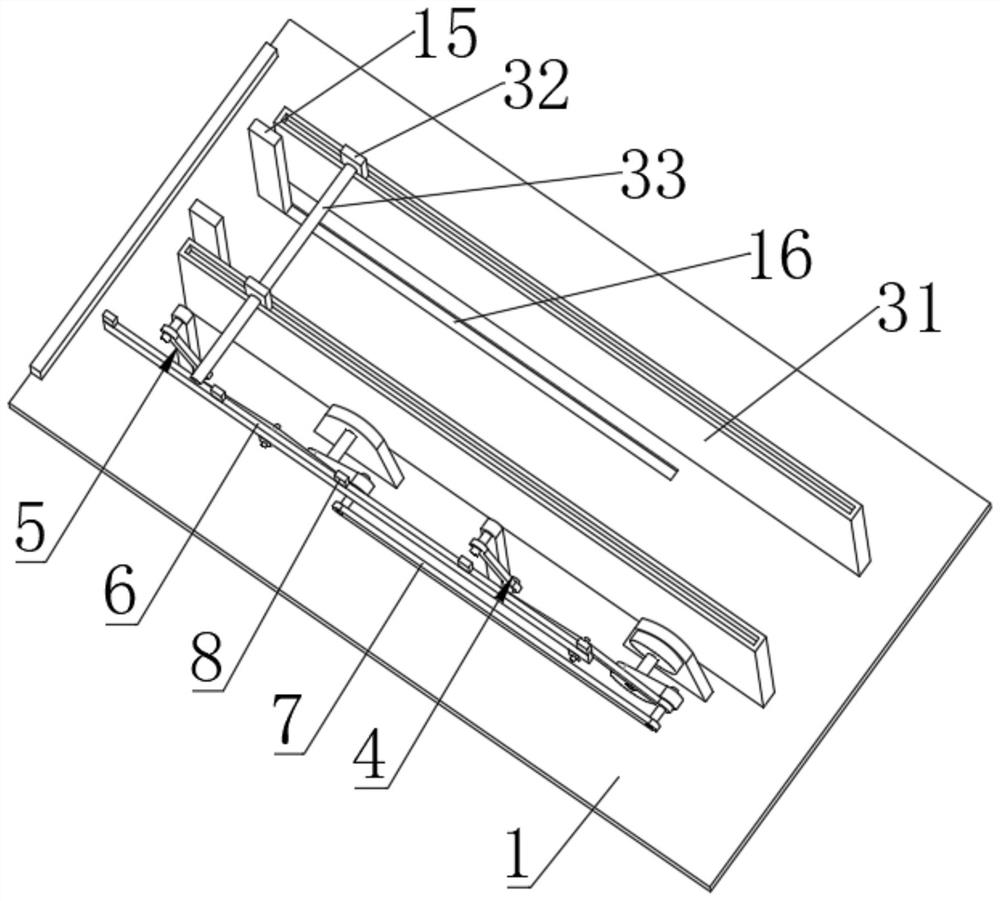

[0030] Such as figure 1 As shown, the present invention provides a kind of asphalt debarrel equipment with an automatic start-stop device, including an outer box 1, through which the internal components and the asphalt cylinder 13 placed later can be protected, and the outer box 1 is provided with a door body 2 on one side, preferably the door body 2 should be easily disassembled for subsequent work. In order to facilitate the removal of the asphalt cylinder 13 inside the outer layer box body 1, a sliding mechanism 3 is provided in the outer layer box body 1 One side of the sliding mechanism 3 is provided with a first driving mechanism 4 and a second driving mechanism 5, so that the outer casing 1 provides support for the sliding mechanism 3, the first driving mechanism 4 and the second drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com