A Wellhead Attitude Monitoring System and Method Suitable for the Whole Process of Deep Water Jet Downpipe

A monitoring system and whole-process technology, applied in surveying, earthwork drilling, wellbore/well components, etc., can solve problems such as inability to carry out construction, visual reading errors, instability of conduit pipe strings, etc., to achieve the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing, the present invention is described in further detail:

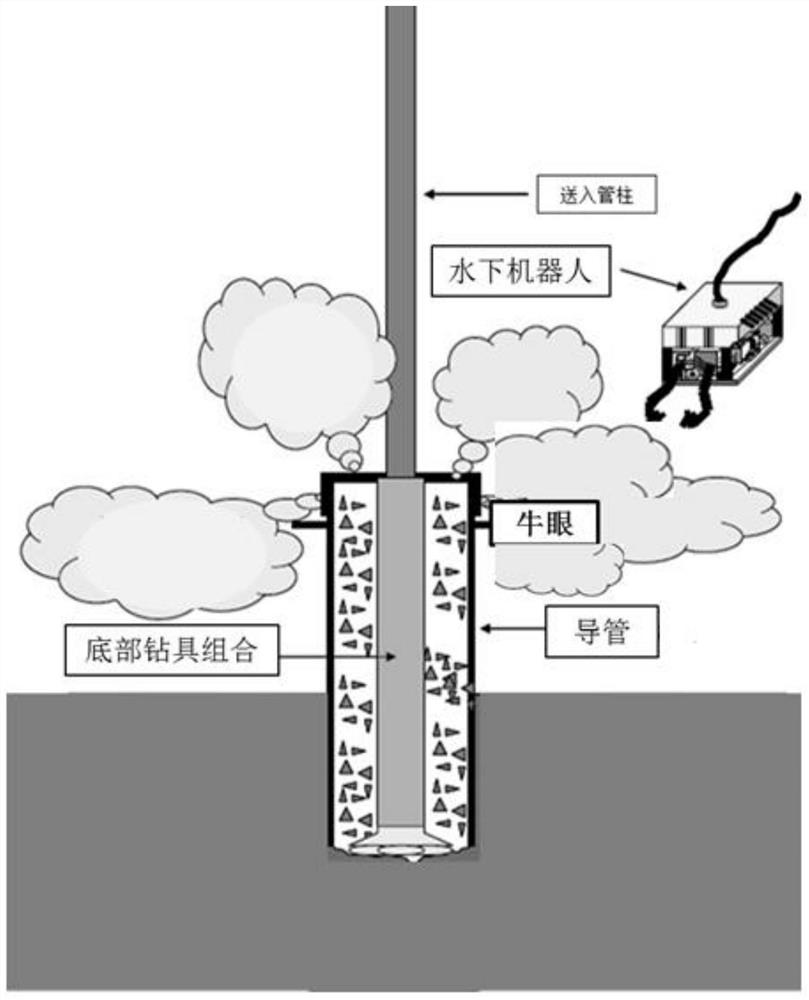

[0043] The system of the present invention comprises a wellhead inclination state monitoring unit, an underwater ROV short-distance signal processing unit, a water surface ROV control and monitoring unit, and a wellhead attitude display unit on a driller's control panel.

[0044] To achieve the above purpose, if image 3 and Figure 4 As shown, the system of the present invention is specifically as follows:

[0045] (1) Wellhead inclination measurement and signal transmission unit

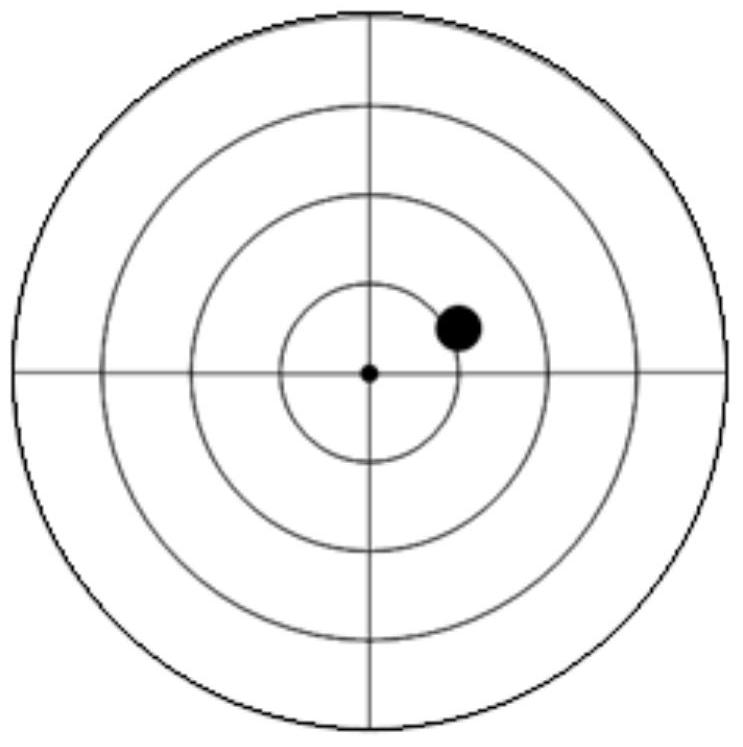

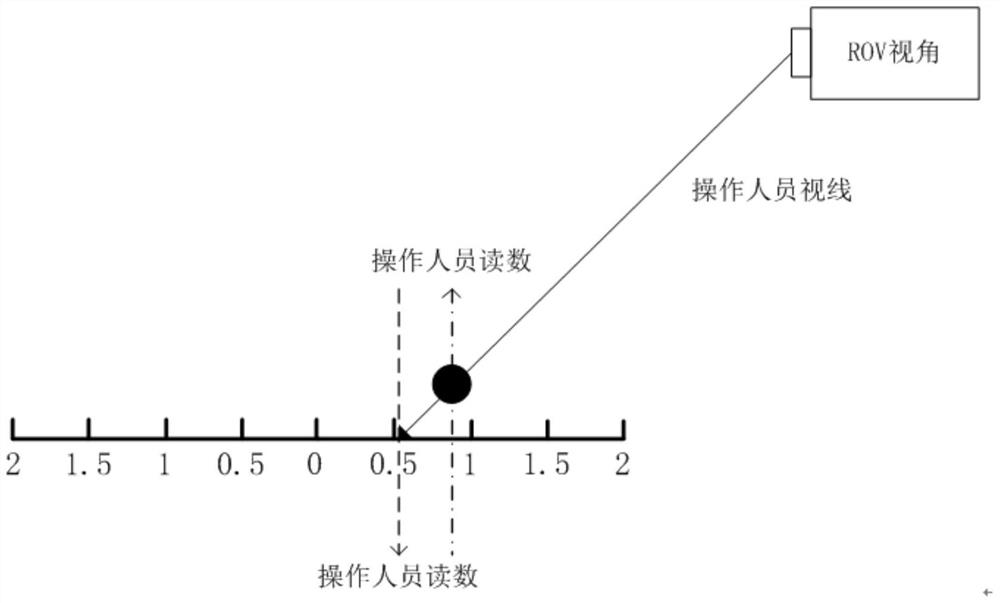

[0046] The wellhead inclination measurement and signal transmission unit is installed on the wellhead or anti-sinking plate. On the basis of the existing bull’s-eye structure, the metal shell on the back is extended to add a series of measurement, signal sending and receiving and control devices, and the outside is replaced with high-pressure resistant The shell meets the deep-water ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com