Rod compression type power connection fixture

A technology of tilting and splicing, applied in the direction of conductive connection, electrical component connection, connection, etc., can solve the problems of limited connection stability, applicability and practicality of power fittings, etc., to ensure the stability, reliability and practicability of the connection. Good and adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

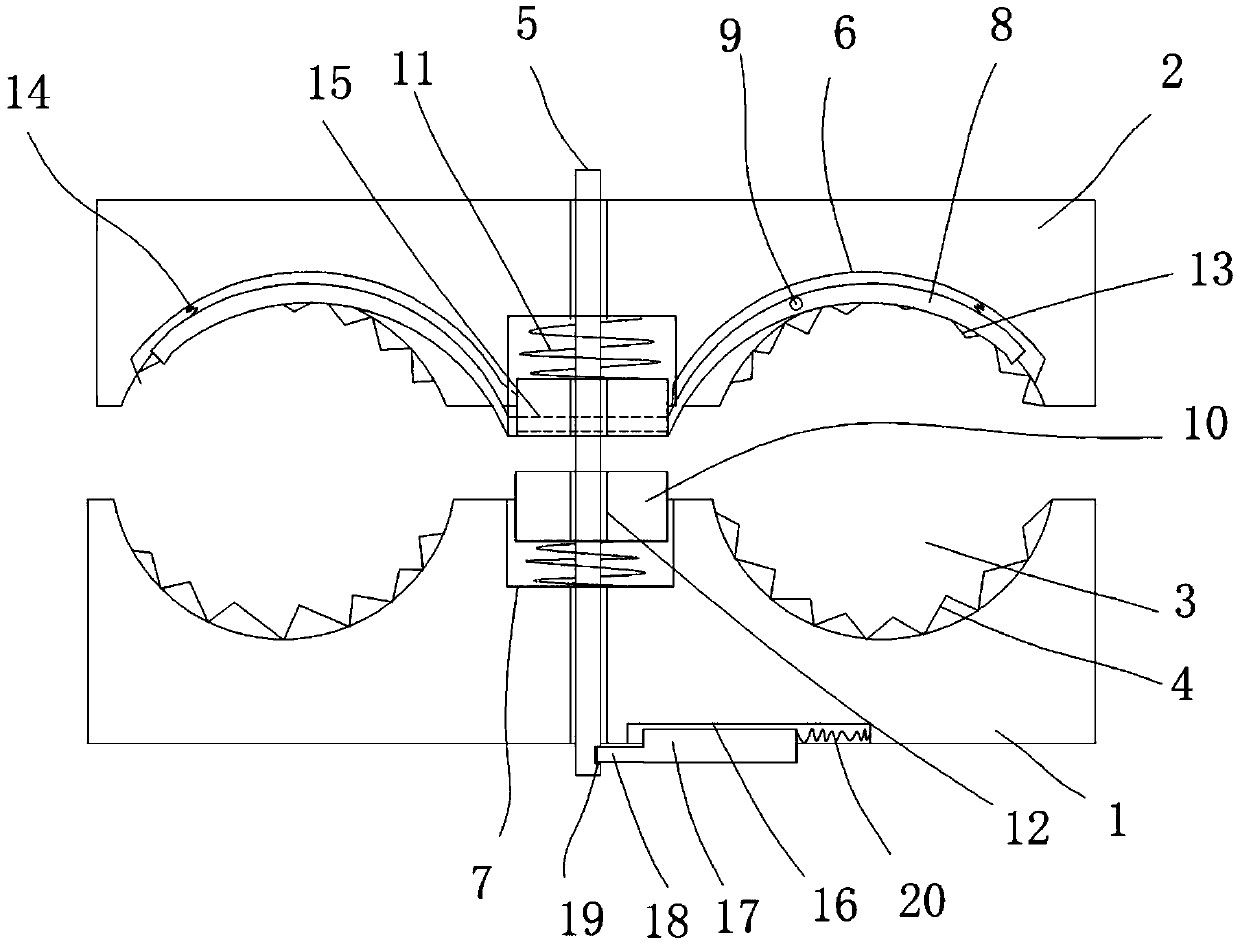

[0014] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0015] See figure 1 , a clamping rod pressing type electric power extension fixture, including a pressure seat 1 and a gland 2, an arc-shaped wire groove 3 is arranged on the crimping surface of the pressure seat and the gland, and an arc-shaped wire groove 3 is arranged on the pressure seat 1 and the gland. The arc-shaped wire groove of the gland 2 is evenly provided with tooth tips 4, the pressure seat and the gland are provided with fastening screws 5, and grooves 6 are arranged on the pressure seat and the gland, and the concave Groove 6 is vertically arranged with described arc-shaped wire groove 3, and the middle part of described pressure base 1 and gland 2 is provided with pressure plate groove 7, and described pressure plate groove 7 is parallel with described arc-shaped wire groove 3, in the The groove 6 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com