Warped rod compression type power continuation fixture and working method thereof

A technology of tilting rods and continuous connections, which is applied to electrical components, equipment for connecting/terminating cables, etc., can solve problems such as applicability and practical limitations, and achieve stable and reliable connections, good insulation, and material components. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

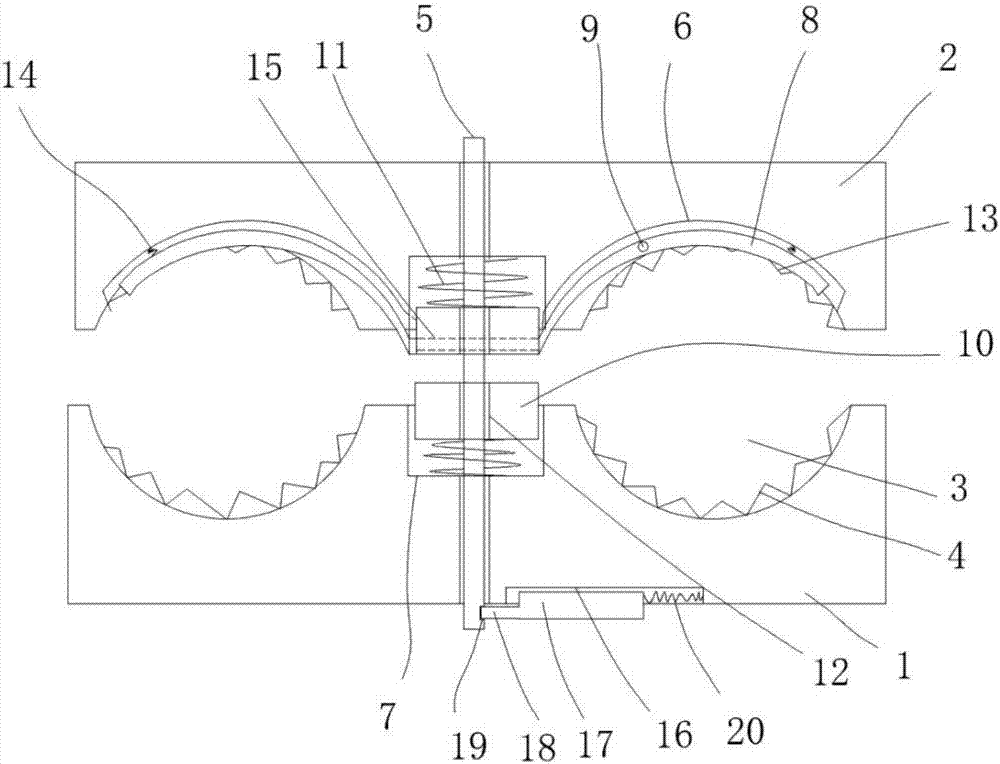

[0027] Such as figure 1 The shown rod pressing type power connection fixture includes a pressure seat 1 and a gland 2, and an arc-shaped wire groove 3 is arranged on the crimping surface of the pressure seat 1 and the gland 2, and on the pressure seat 1 and the arc-shaped wire groove 3 of the gland 2 are evenly provided with tooth tips 4, the pressure seat 1 and the gland 2 are provided with fastening screws 5, and the pressure seat 1 and the gland 2 are provided with Groove 6, the groove 6 and the arc-shaped wire groove 3 are vertically arranged, and the middle part of the pressure seat 1 and the gland 2 is provided with a pressure plate groove 7, and the pressure plate groove 7 is connected with the arc-shaped wire groove 3 are parallel to each other, an arc-shaped warping rod 8 is arranged in the groove 6, the middle part of the arc-shaped warping rod 8 is connected in the groove 6 through a rotating shaft 9, and a pressure plate body is arranged in the pressure plate groov...

Embodiment 2

[0039] Such as figure 1 The cocking rod compression type power connection fixture shown includes a pressure seat 1 and a gland 2, and an arc-shaped wire groove 3 is arranged on the crimping surface of the pressure seat 1 and the gland 2. On the pressure seat 1 and the arc-shaped wire groove 3 of the gland 2 are uniformly provided with tooth tips 4, the pressure seat 1 and the gland 2 are provided with fastening screws 5, and the pressure seat 1 and the gland 2 are provided with Groove 6, the groove 6 and the arc-shaped wire groove 3 are vertically arranged, and the middle part of the pressure seat 1 and the gland 2 is provided with a pressure plate groove 7, and the pressure plate groove 7 is connected with the arc-shaped wire groove 3 are parallel to each other, an arc-shaped warping rod 8 is arranged in the groove 6, the middle part of the arc-shaped warping rod 8 is connected in the groove 6 through a rotating shaft 9, and a pressure plate body is arranged in the pressure p...

Embodiment 3

[0051] Such as figure 1 The shown rod pressing type power connection fixture includes a pressure seat 1 and a gland 2, and an arc-shaped wire groove 3 is arranged on the crimping surface of the pressure seat 1 and the gland 2, and on the pressure seat 1 and the arc-shaped wire groove 3 of the gland 2 are evenly provided with tooth tips 4, the pressure seat 1 and the gland 2 are provided with fastening screws 5, and the pressure seat 1 and the gland 2 are provided with Groove 6, the groove 6 and the arc-shaped wire groove 3 are vertically arranged, and the middle part of the pressure seat 1 and the gland 2 is provided with a pressure plate groove 7, and the pressure plate groove 7 is connected with the arc-shaped wire groove 3 are parallel to each other, an arc-shaped warping rod 8 is arranged in the groove 6, the middle part of the arc-shaped warping rod 8 is connected in the groove 6 through a rotating shaft 9, and a pressure plate body is arranged in the pressure plate groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com