Intelligent heat dissipation dust cover for transformers and working method thereof

A working method and transformer technology, which is applied in the field of transformers, can solve the problems of applicability and practicability limitations, easily damaged transformers, and affecting heat dissipation performance, and achieve the effects of ensuring stable and reliable connections, good practicability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

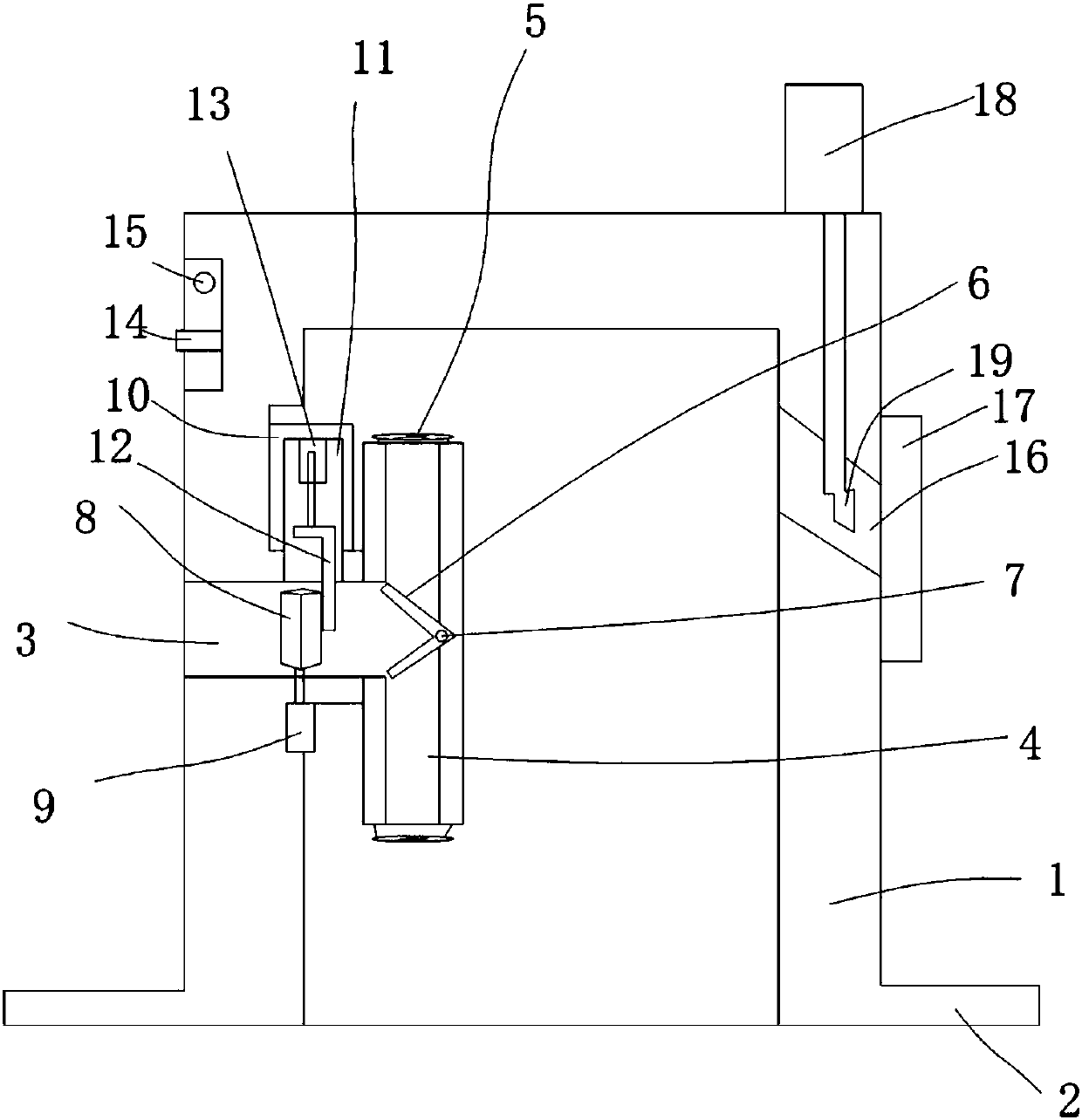

[0021] Such as figure 1 The shown intelligent heat dissipation dust cover for transformers includes a cover body 1, on which the installation and fixing lugs 2 are arranged, and on the side wall of the cover body 1, heat dissipation holes 3 are arranged, A T-shaped air guide pipe 4 is arranged inside the cover body 1, and the vertical pipe of the T-shaped air guide pipe 4 communicates with the heat dissipation hole 3, and at both ends of the horizontal pipe of the T-shaped air guide pipe 4 All are provided with cooling blower fan 5, be provided with baffle plate 6 at the horizontal tube center of described T-shaped air guide pipe 4, the top of described baffle plate 6 is connected on the horizontal tube of T-shaped air guide tube 4 by rotating shaft 7 and The bottom end of the baffle plate 6 is movable on both sides of the vertical pipe opening of the T-shaped air guide pipe 4 under the action of the two cooling fans 5, and at least two A dust shield 8 is provided with a smal...

Embodiment 2

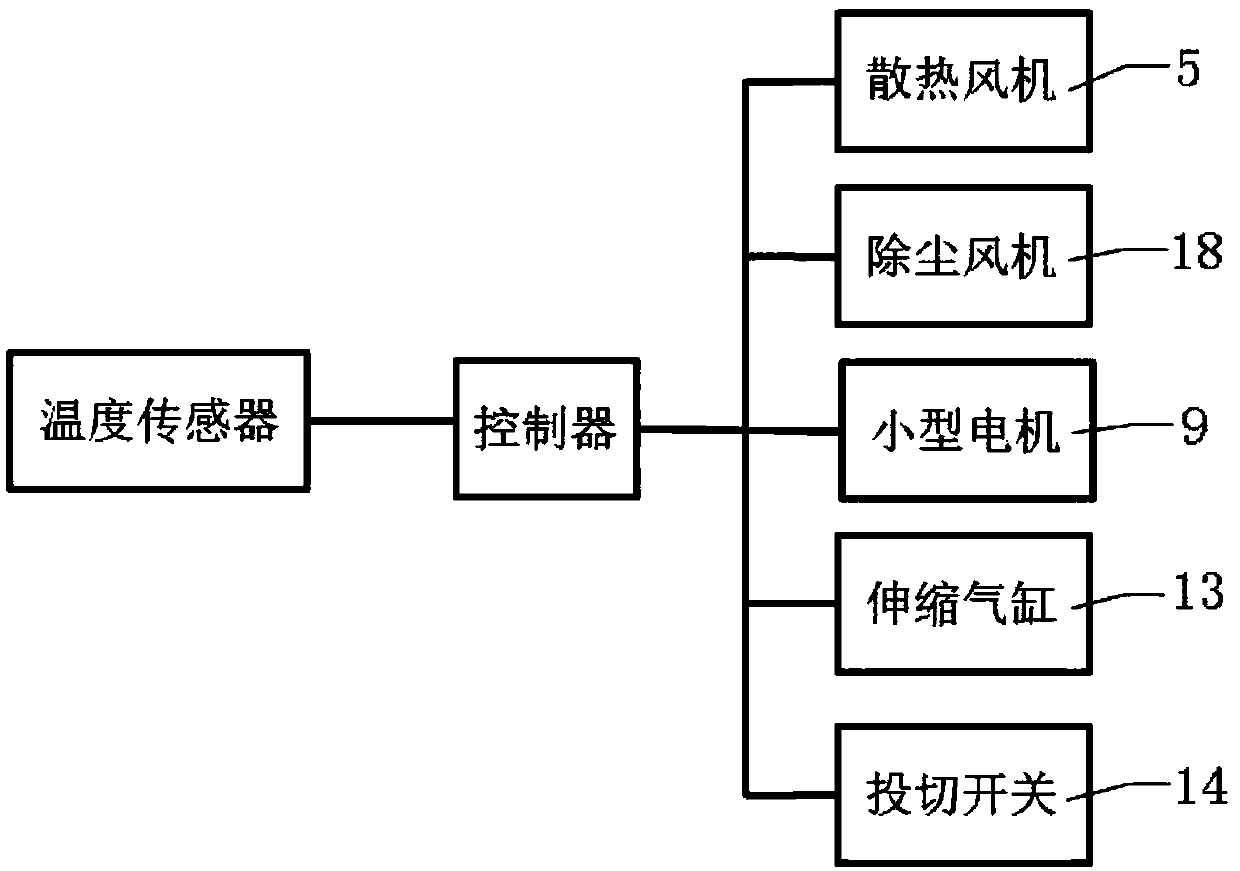

[0028] During work, based on the structural basis of Embodiment 1, the following steps are included: the temperature sensor detects that the preset value is exceeded in the cover body 1, and the information is sent to the controller, and the controller controls the heat dissipation at one end of the T-shaped air duct 4 horizontal tubes The fan 5 works, the cold air enters the cover body 1 from the air inlet channel 16, and the baffle 6 rotates along the rotating shaft 7; the hot air is discharged from the cooling hole 3; after a period of time, the controller controls the switching switch 14 to switch the T-shaped air guide The cooling fan 5 at the other end of the tube 4 and the horizontal tube works, and the above process is repeated to realize that the two cooling fans 5 work alternately. At the same time, the controller controls the dust removal fan 18 to work, and the cold air blows through the air nozzle 19 to remove dust, effectively ensuring the cleanliness of the cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com