Integral flue of hot blast stove

An integral, hot blast stove technology, applied in lighting and heating equipment, combustion methods, exhaust gas devices, etc., can solve the problems of shortening the service life of the flue, damage to the flue by soot, and reflux of soot, etc., and achieves convenient installation and disassembly. Good dust blocking effect and easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

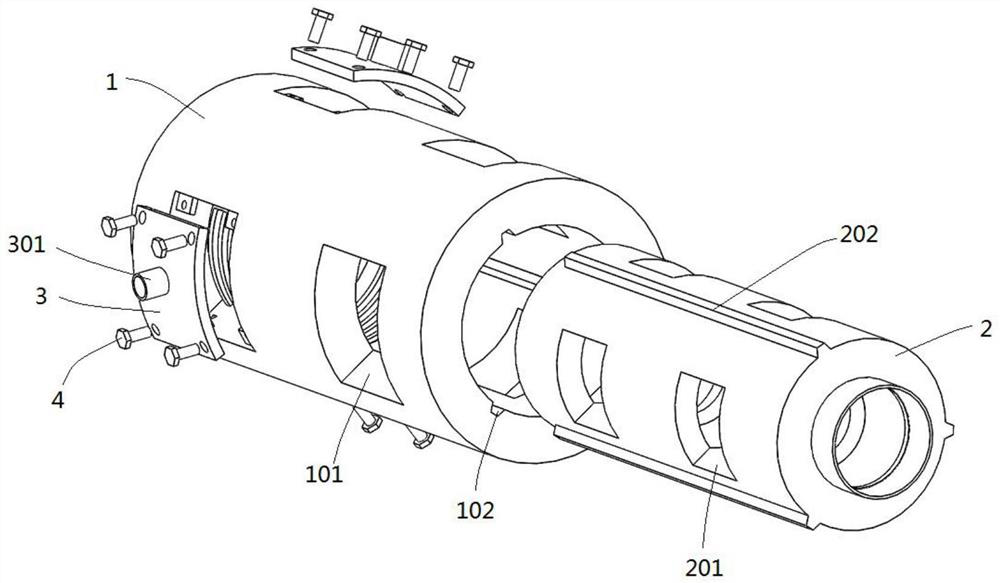

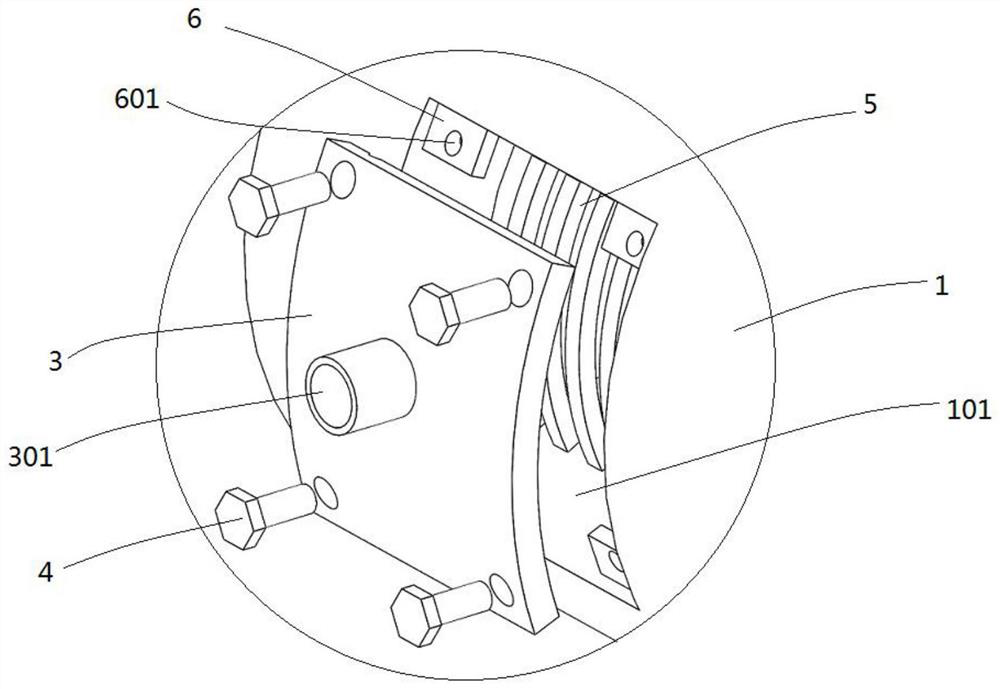

[0024] Embodiment 1: see Figure 1-2 , the integrated flue of the hot blast stove, including an outer flue 1 and an inner lining 2, one end of the outer flue 1 is provided with a smoke inlet pipe 10, and a plurality of installation holes 101 are distributed around the shell of the outer flue 1, each Filter screens 5 are arranged in the installation holes 101 , and the outer ports of the installation holes 101 are detachably connected with the dust removal cover 3 , and the outer surface of the dust removal cover 3 is provided with a connecting pipe 301 .

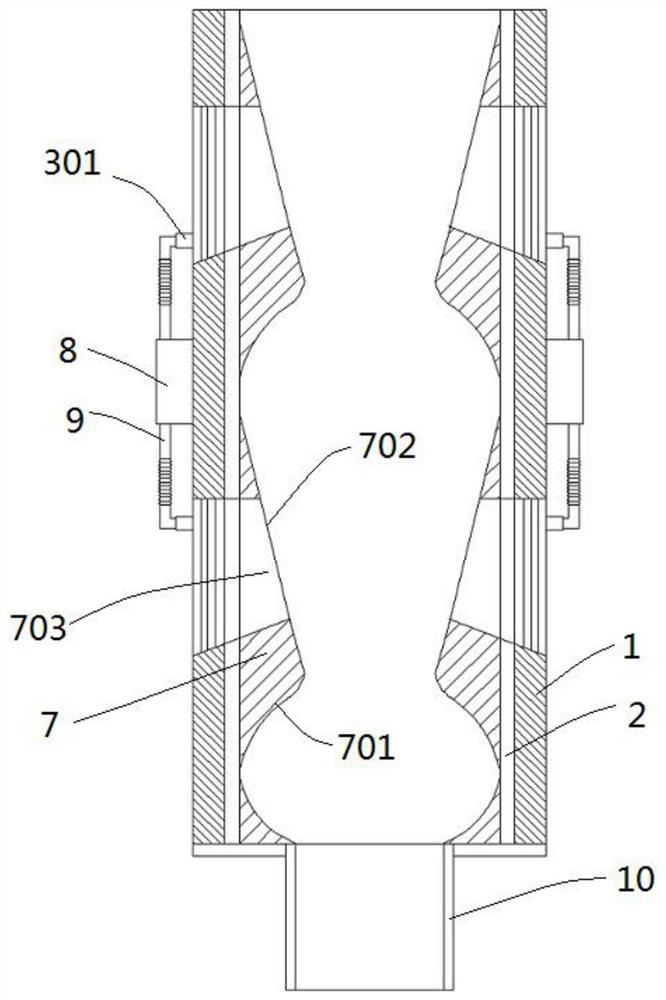

[0025] The inner lining 2 is installed and fixed on the inner wall of the outer flue 1, and the shell of the inner lining 2 is distributed with gaps 201 corresponding to the installation holes 101, and the inner wall of the inner lining 2 is fixed with a number of dust blocking blocks 7 along the circumferential direction. The dust block 7 is annular and cylindrical, and the side of the inner wall of the dust blocking block ...

Embodiment 2

[0027] Example 2: see figure 1 , figure 2 , image 3 , Figure 4 , the integrated flue of the hot blast stove, including an outer flue 1 and an inner lining 2, one end of the outer flue 1 is provided with a smoke inlet pipe 10, and a plurality of installation holes 101 are distributed around the shell of the outer flue 1, each Filter screens 5 are arranged in the installation holes 101 , and the outer ports of the installation holes 101 are detachably connected with the dust removal cover 3 , and the outer surface of the dust removal cover 3 is provided with a connecting pipe 301 .

[0028] The inner lining 2 is installed and fixed on the inner wall of the outer flue 1, and the shell of the inner lining 2 is distributed with gaps 201 corresponding to the installation holes 101, and the inner wall of the inner lining 2 is fixed with a number of dust blocking blocks 7 along the circumferential direction. The dust block 7 is annular and cylindrical, and the side of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com