Stereoscopic warehouse

A three-dimensional warehouse and track technology, applied in the field of three-dimensional warehouses, can solve the problems of low efficiency, many supporting equipment, complex structure of roadway stackers, etc., and achieve the effect of low cost and high transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

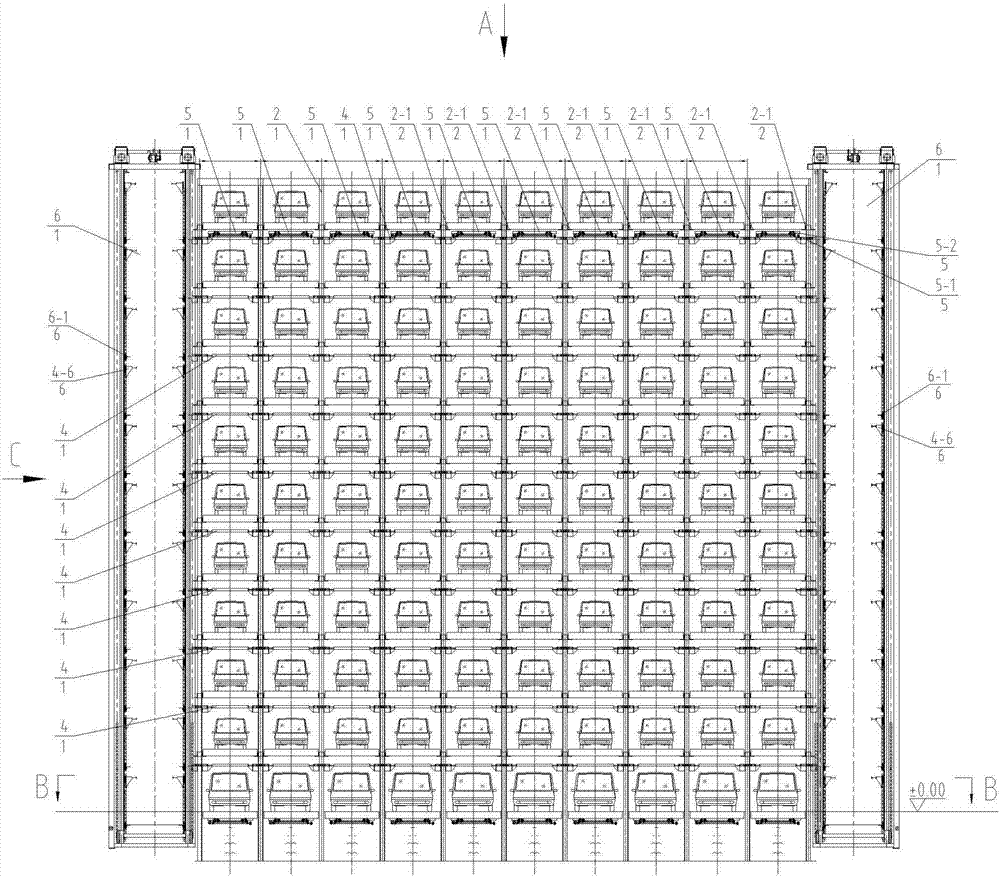

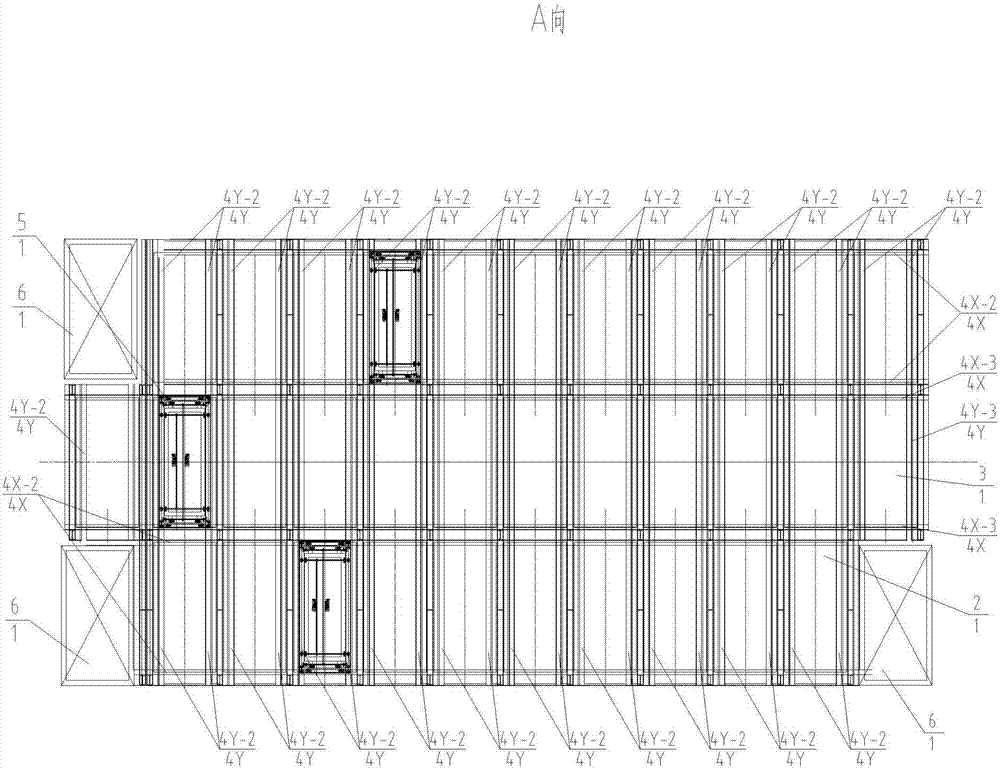

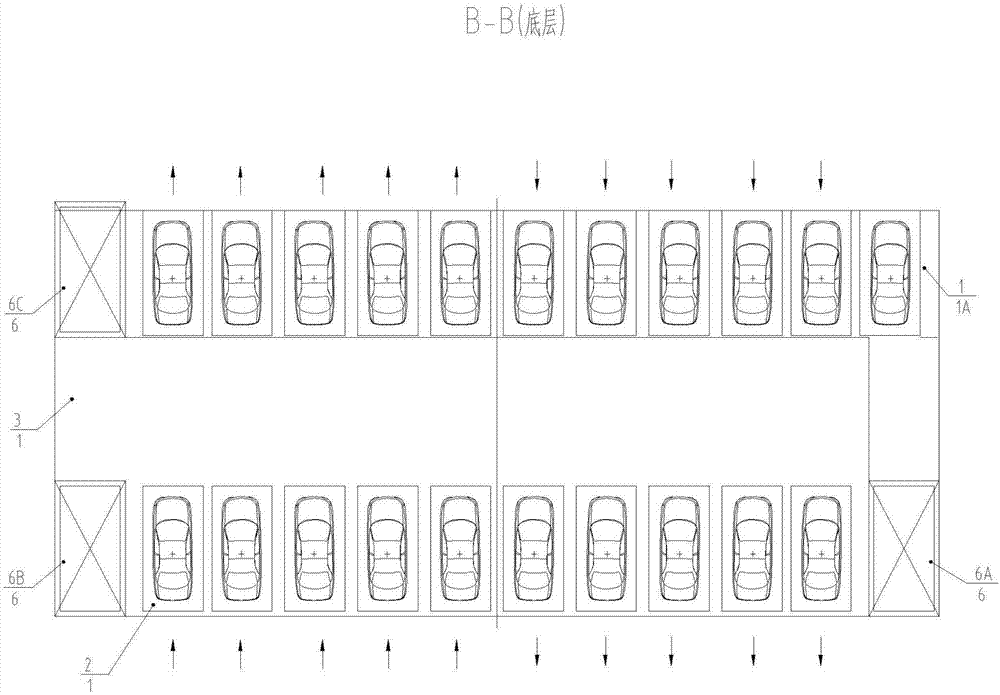

[0023] The three-dimensional warehouse 1 includes shelves 2, lanes 3, rails 4, carrying trolleys 5 and elevators 6; the shelves 2 include several layers of brackets 2-1, and the supporting surfaces of the brackets 2-1 support the bottom surface of pallets or articles; two adjacent rows The shelves 2 share a roadway 3; the track 4 includes a track 4X on which the carrying car 5 runs in the X direction and a track 4Y on which the carrying car 5 runs in the Y direction, and several layers of the track 4X on which the carrying car 5 runs in the X direction are arranged in the roadway 3 -3; the rack 2 is provided with a track 4Y-2 for carrying a trolley 5 running in the Y direction, and the roadway 3 is provided with a track 4Y-3 for carrying a trolley 5 running in the Y direction; A traveling device 5-1 and a jacking device 5-2 that can run in the Y direction; when the device 5-1 is on the track 4Y-2 and the device 5-2 is retracted, the upper plane of the device 5-2 is lower than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com