Dual-water-seal and dual-gas-seal clean floor drain for pharmaceutical workshop

A floor drain, water vapor technology, applied in waterway systems, water supply devices, drainage structures, etc., can solve problems such as the increase in the amount of steam, air and water, the inability to meet the sealing problem of the sewage system, the short-term pressure of the sewage system, etc., to achieve tightness improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

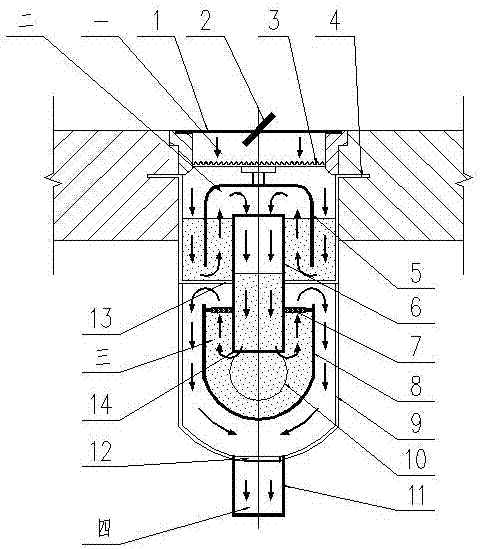

[0020] The present invention includes a floor drain body 9, a partition 13 is arranged inside the floor drain body 9, and a communication cup 6 passing through the partition 13 is arranged inside the floor drain body 9;

[0021] The floor drain body 9 is provided with an upper water seal cylinder 5 and a lower water seal cylinder 8;

[0022] The upper water seal cylinder 5 is located on the upper part of the partition plate 13, and is set upside down on the outside of the connecting cup 6. There are gaps between them to form sewage channels;

[0023] The lower water seal cylinder 8 is located at the bottom of the partition plate 13, and is sleeved on the outside of the communication cup 6. There are gaps between the lower water seal cylinder 8 and the partition plate 13, and between the lower water seal cylinder 8 and the communication cup 6. The gap forms a sewage channel;

[0024] The bottom of the communication cup 6 is provided with a float valve 10 for blocking the sewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com