Air vent having a control device

A technology for controlling air and air, applied in air handling equipment, transportation and packaging, heating/cooling equipment, etc., can solve problems such as unsealed closure, increased gap between size components, insufficient sealing of air supply channels, etc., to achieve Reduced production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

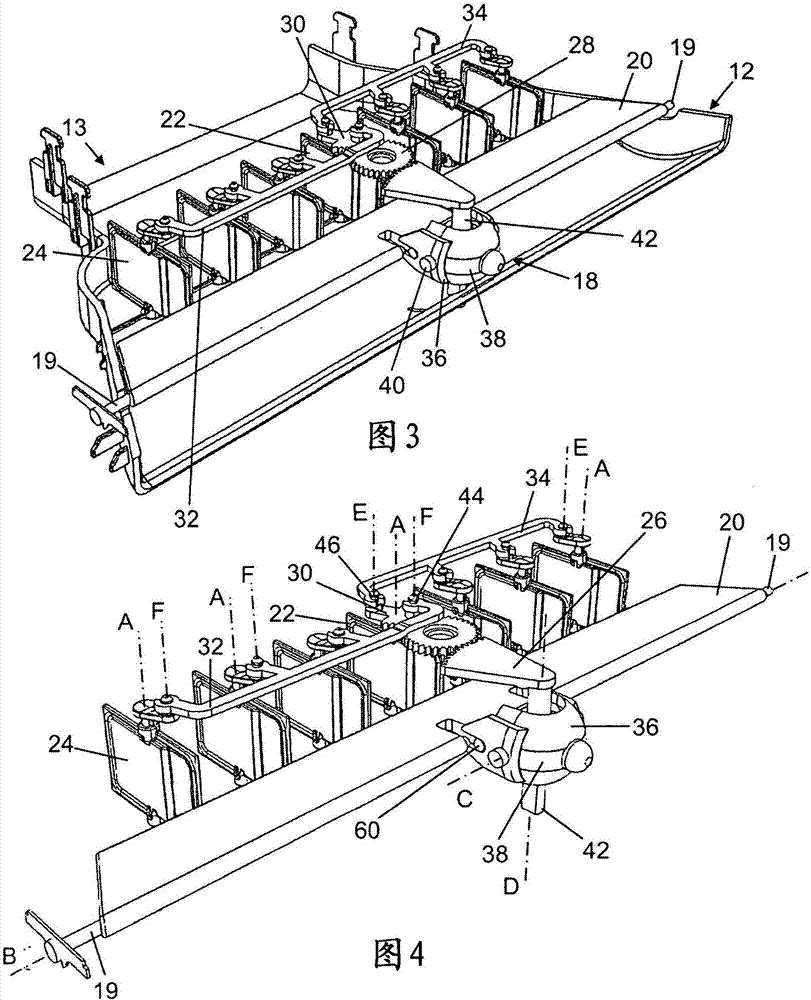

[0056] Components with the same reference numerals in the figures are substantially the same unless otherwise stated. Furthermore, a description of the components of the air outflow device for controlling the air flow that are not necessary for understanding the technical teaching disclosed herein is omitted.

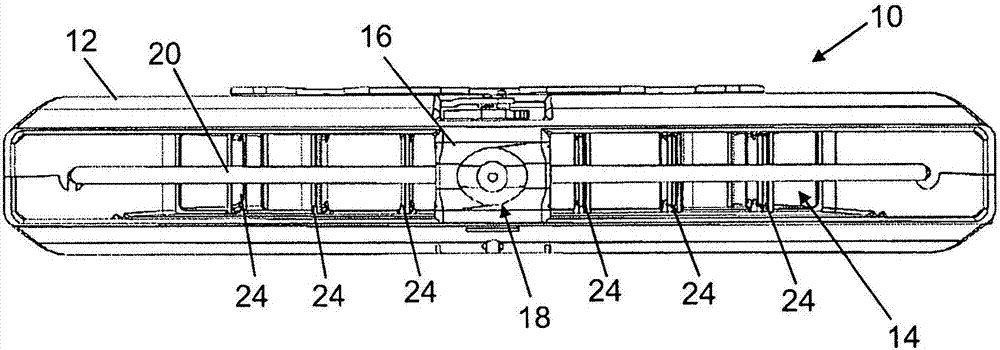

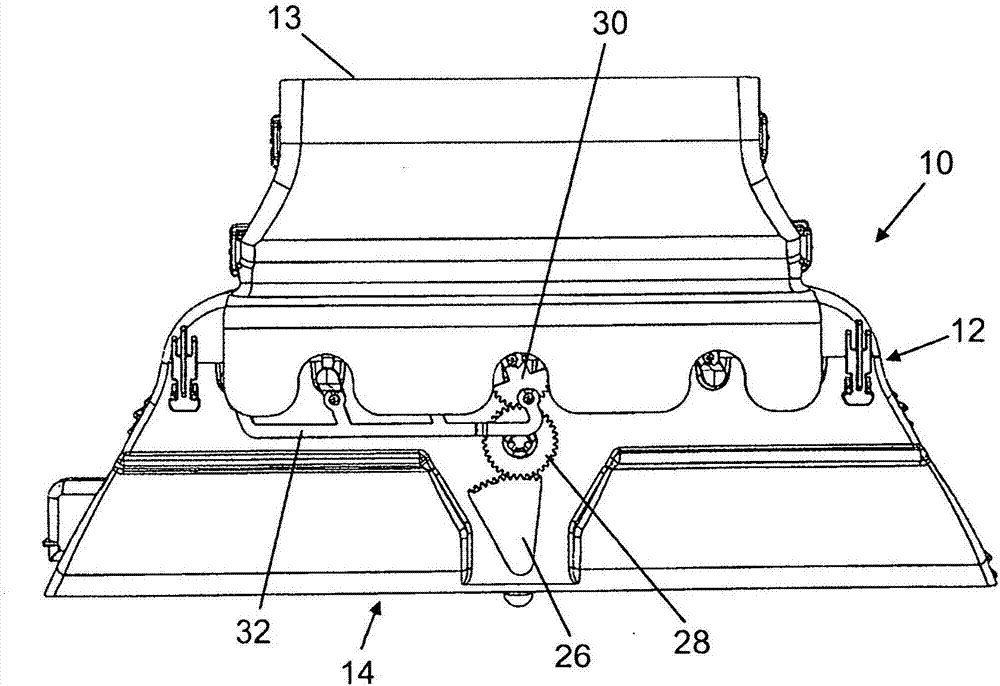

[0057] Figures 1 to 30 The shown air outlet 10 and its components can be arranged, for example, in the region of the center console of a vehicle dashboard. The air outflow device 10 is designed here as a so-called broadband ejector. This means that the air outlet 10 is wider than it is high in the air outlet region 14 . Preferably, the air outlet region 14 has a width of greater than 200 mm, preferably greater than 300 mm.

[0058] In the following description, the terms "rotate" and "pivot" are often used synonymously. For example, the pivotable blade can also be rotated about its axis of rotation and the rotatably mounted actuating element can be pivoted about it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com