Adjustable workbench

A workbench and sliding seat technology, which is applied in the field of machine tool feeding devices, can solve problems such as the inability to adjust the position of the workbench

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

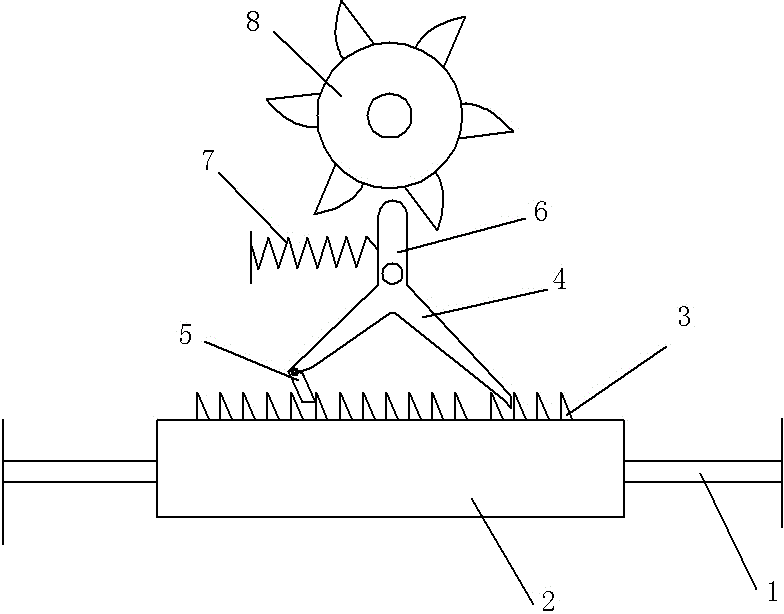

[0009] The reference signs in the accompanying drawings of the description include: sliding rod 1, sliding seat 2, tooth 3, V-shaped frame 4, moving claw 5, protruding rod 6, ratchet 7, extension spring 8.

[0010] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

[0011] Such as figure 1 As shown, an adjustable workbench includes a frame, a motor, a slide bar 1 and a slide seat 2, the two ends of the slide bar 1 are fixed on the frame by screws and nuts, and the slide seat 2 slides with the slide bar 1 Connection, a pulley with a groove at the joint between the slider 2 and the slider 1, this embodiment is preferably a V-shaped pulley, the worktable is welded to the slider 2, and the upper surface of the slider is evenly distributed with teeth 3, the teeth 3 of the slider A V-shaped frame 4 is installed on the frame above. One end of the V-shaped frame 4 is a fixed claw, and the other end is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com