Inner diameter measuring device for tubular anastomat

A measuring device and stapler technology, which is applied in the field of medical devices, can solve problems such as data reading trouble, tube drop, movable measuring head moving back, etc., to achieve the effect of convenient inner diameter measurement, convenient operation, and avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

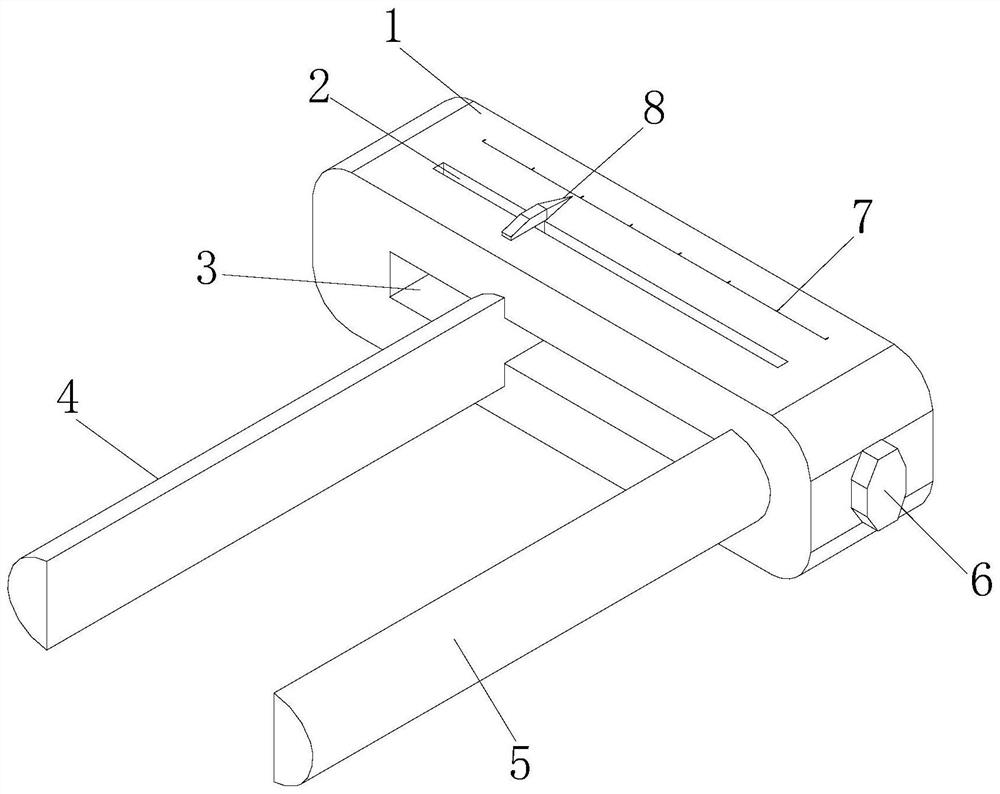

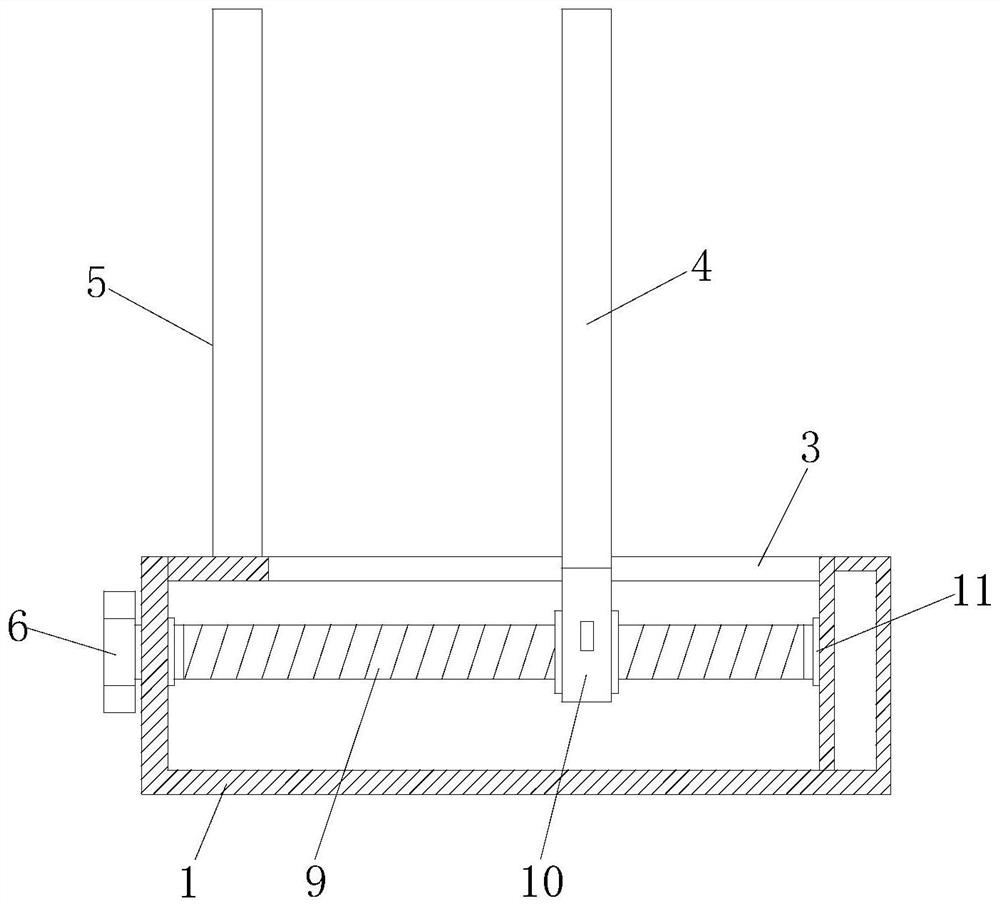

[0028] see Figure 1-6 , the present invention provides the following technical solutions: a tubular stapler internal diameter measuring device, including a base 1, the base 1 inside is provided with a screw 9, the surface of the screw 9 is provided with a sliding seat 10, one end of the sliding seat 10 The movable measuring head 4 is connected, the side of the base 1 is provided with a fixed measuring head 5, the side of the base 1 is provided with an adjusting bolt 6 connected with the screw rod 9, the upper end of the sliding seat 10 is provided with a pointer 8, the base The surface of 1 is provided with a notch 2 corresponding to the position of the pointer 8, the side surface of the base 1 is located on the side of the notch 2, and a scale 7 is provided, and the side of the base 1 is provided with a stop for the movable measuring head 4 to limit sliding. Slide track 3.

[0029] Furthermore, in the present invention, both ends of the screw rod 9 are rotationally connecte...

Embodiment 2

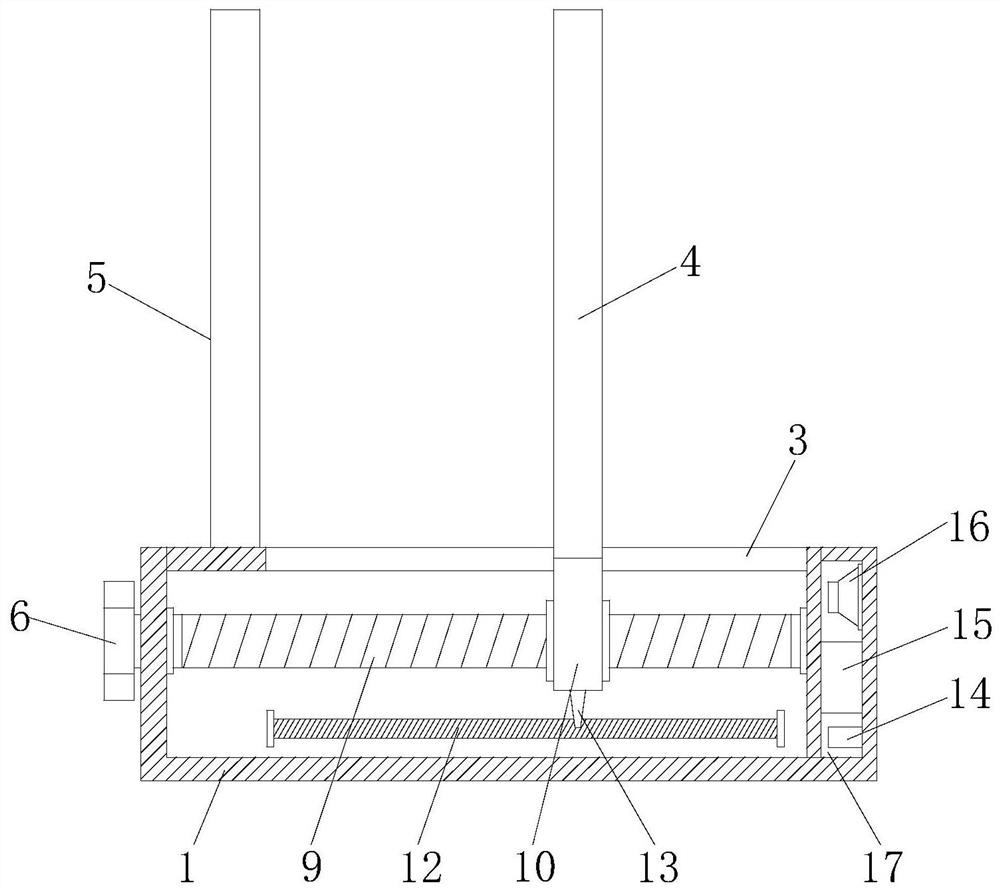

[0032] The difference between this embodiment and Embodiment 1 is that the inside of the base 1 is provided with a sliding resistor 12 on the side away from the sliding track 3, the side of the sliding seat 10 is provided with a connecting contact piece 13, and the inside of the base 1 is far away from the adjustment One side of the bolt 6 is provided with a placement cavity 17, and a storage battery 15 is provided in the middle of the storage cavity 17, a horn 16 is provided on one side of the storage battery 15, and a PLC control module 14 is provided on the other side of the storage battery 15.

[0033] Further in the present invention, a display screen 18 is provided on the surface of the base 1 at the side of the scale 7 .

[0034] Further in the present invention, the sliding resistor 12 , the PLC control module 14 , the speaker 16 and the display screen 18 are all connected to the storage battery 15 .

[0035] Further in the present invention, the connecting contact pie...

Embodiment 3

[0038] This embodiment differs from Embodiments 1 and 2 in that: the base 1 is provided with a fixed plate 19 on the side of the fixed measuring head 5, and the side of the fixed plate 19 close to the fixed measuring head 5 is provided with a pressing plate 21, and the pressing plate 21 and The fixed plates 19 are connected by return springs 20 .

[0039] Further in the present invention, the end of the pressing plate 21 away from the base 1 is arranged in an arc-shaped structure.

[0040] When using this embodiment, the fixed measuring head 5 is inserted into the tubular stapler, and the pressing plate 21 is located on the outer wall of the tube. The elastic force of the return spring 20 makes the pressing plate 21 close to the outer wall of the tube, so that the fixed measuring head 5 cooperates with the pressing plate 21. Realize the clamping and fixing of the tube to avoid falling off due to no hand support during measurement, and then rotate the adjusting bolt 6 to drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com