Anti-scraping coating for plastic and preparation method of anti-scraping coating

An anti-scratch, plastic technology, applied in the field of coatings, can solve the problems of easy scratching of the coating, product surface damage, unfavorable long-term protection of the product surface, etc., achieve good reflectivity, improve scratch resistance, and be beneficial to aesthetics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

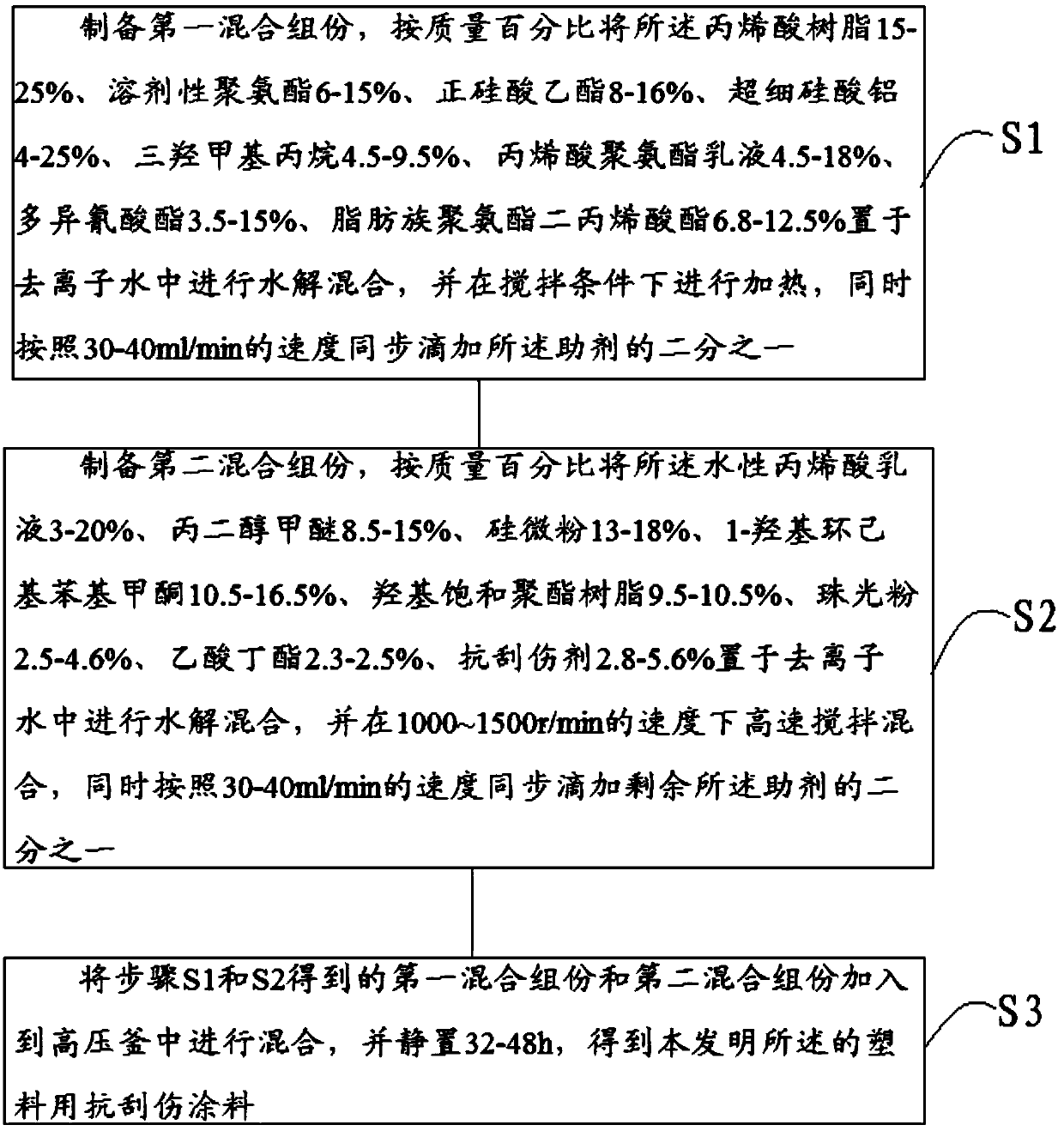

Method used

Image

Examples

Embodiment 1

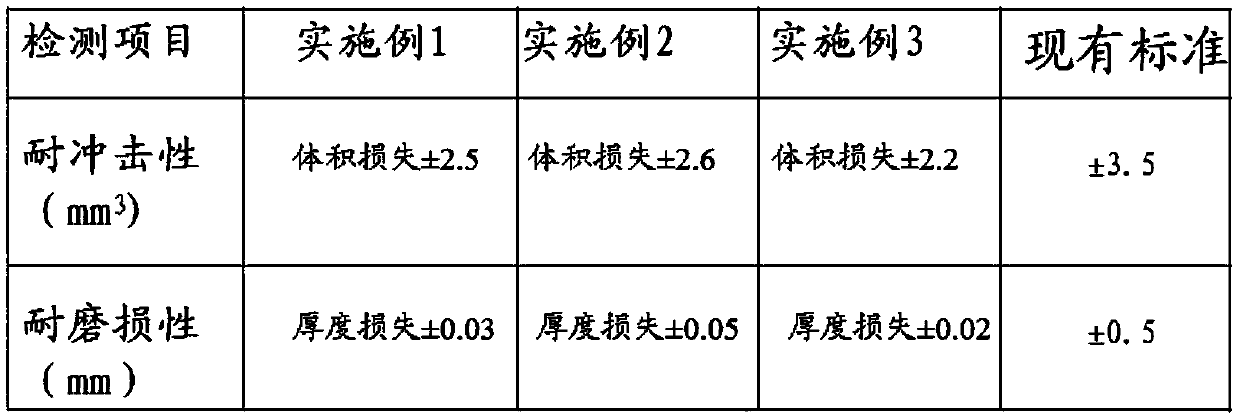

[0034] Prepare the first mixed component, by mass percent, the acrylic resin 25%, solvent-based polyurethane 15%, tetraethyl orthosilicate 8%, superfine aluminum silicate 4%, trimethylolpropane 4.5%, acrylic polyurethane 4.5% of emulsion, 3.5% of polyisocyanate, and 6.8% of aliphatic polyurethane diacrylate are placed in deionized water for hydrolysis and mixing, and heated under stirring conditions, and at the same time, 2% of the auxiliary agent is synchronously added dropwise at a speed of 40ml / min. one-third. The second mixed component is prepared, and the water-based acrylic emulsion 3%, propylene glycol methyl ether 8.5%, silicon micropowder 13%, 1-hydroxycyclohexyl phenyl ketone 10.5%, hydroxyl saturated polyester resin 9.5%, Put 2.5% of pearl powder, 2.5% of butyl acetate, and 5.6% of anti-scratch agent in deionized water for hydrolysis and mixing, and stir and mix at a speed of 1000r / min, and simultaneously drop them at a speed of 30-40ml / min One-half of the remainin...

Embodiment 2

[0036] To prepare the first mixed component, 10% of the organosilicon-modified acrylic resin, 15% of nano-silicon dioxide, 16% of hydroxyl-terminated fluorine-containing polysiloxane, 1.8% of rosin resin, and 4.8% of organic fluorocarbon resin were prepared by mass percentage. %, 25% nano-titanium dioxide, 9.5% silicon-titanium composite microspheres, 18% sodium carbonate, 15% rutile titanium dioxide, and 12.5% ethyl tetrasilicate were placed in deionized water for hydrolysis and mixing, and heated under stirring conditions , and simultaneously drop half of the auxiliary agent synchronously at a speed of 30-40ml / min. Prepare the second mixed component, by mass percent, the long-chain alkyl acrylate 3%, composite antifouling agent 8.5%, nano-silver particles 13%, nano-magnesium hydroxide 16%, anti-rust pigment 8.5%, poly-ophthalmic Phenylenediamine-nano-copper 5.5%, nano-calcium zirconate 4.6%, nano-fumed silica 1.2%, ethylene glycol butyl ether 7.2%, nano-carbon fiber 4.5%, ...

Embodiment 3

[0038] To prepare the first mixed component, 10% of the organosilicon-modified acrylic resin, 15% of nano-silicon dioxide, 16% of hydroxyl-terminated fluorine-containing polysiloxane, 5.3% of rosin resin, and 4.8% of organic fluorocarbon resin were prepared by mass percentage. %, 25% nano-titanium dioxide, 9.5% silicon-titanium composite microspheres, 18% sodium carbonate, 15% rutile titanium dioxide, and 12.5% ethyl tetrasilicate were placed in deionized water for hydrolysis and mixing, and heated under stirring conditions , and simultaneously drop half of the auxiliary agent synchronously at a speed of 30-40ml / min. Prepare the second mixed component, by mass percent, the long-chain alkyl acrylate 3%, composite antifouling agent 8.5%, nano-silver particles 13%, nano-magnesium hydroxide 16%, anti-rust pigment 8.5%, poly-ophthalmic Phenylenediamine-nano copper 5.5%, nano calcium zirconate 4.6%, nano fumed silica 1.2%, nano carbon fiber 2.8%, sodium borohydride 7.2%, polyvinyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com