Refractory lining combination brick of shaft kiln

A technology of refractory lining and combined bricks, which is applied in the direction of furnace components, furnaces, lighting and heating equipment, etc., can solve the problems of poor stability of the overall structure of the lining, achieve multiple hanging points of the suspension structure, stable physical structure, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

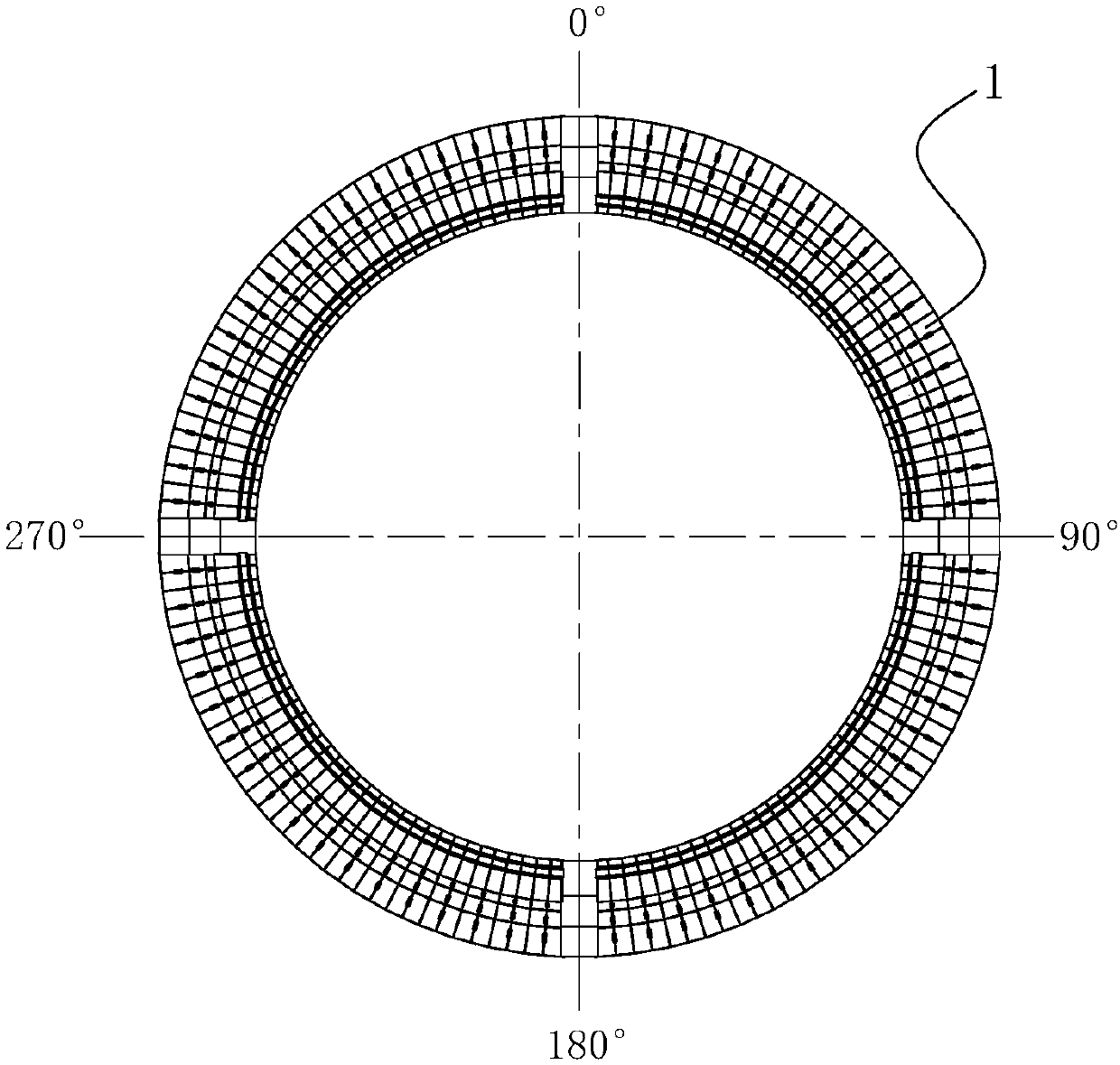

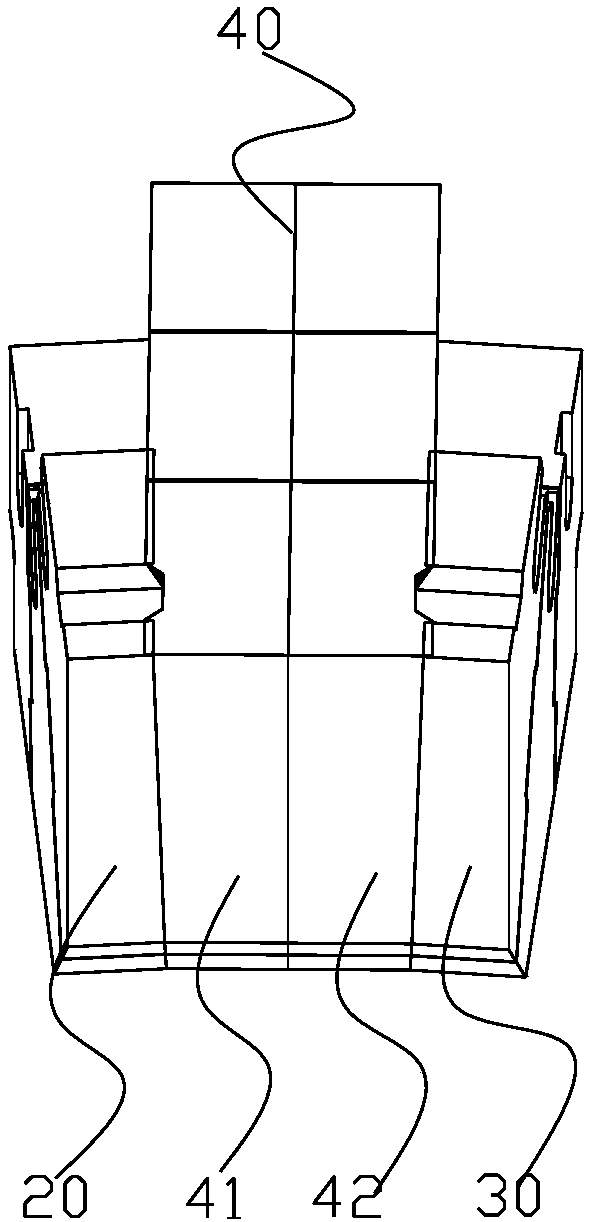

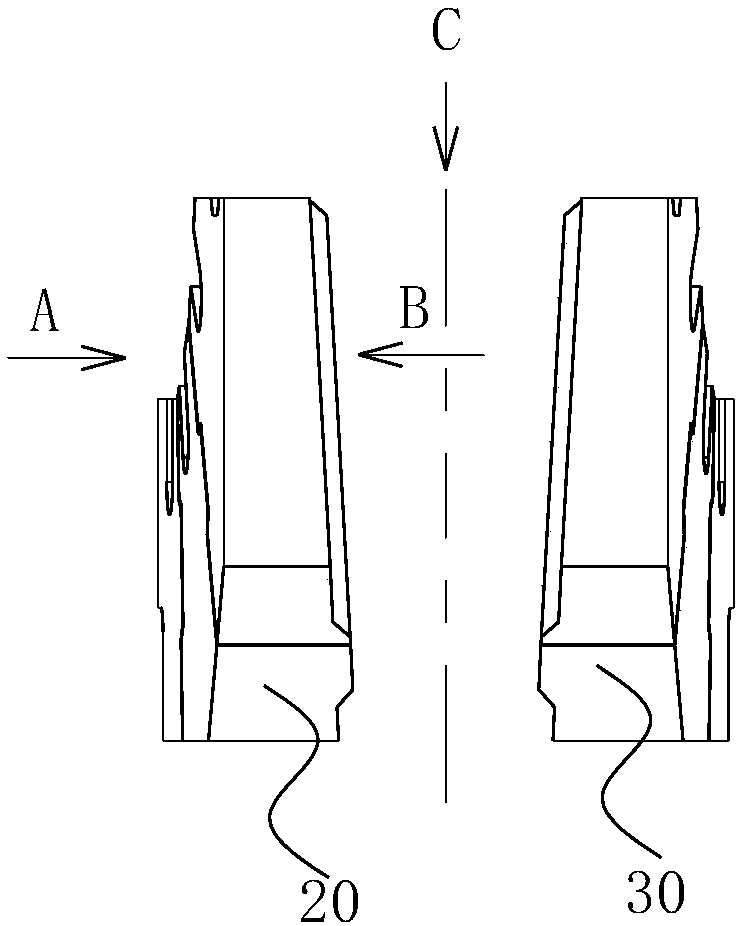

[0032] like figure 1 and figure 2 as well as image 3 As shown, this embodiment provides a shaft kiln refractory lining composite brick, which is used to be installed at the closing position on the shaft kiln refractory lining, wherein the closing position has four areas, distributed in the On the two centerlines perpendicular to each other on the horizontal projection view of the shaft kiln, the combined bricks include the first support brick 20, the second support brick 30, and the first support brick 20 and the second support brick 30 The door closing brick 40 between them, wherein the first supporting brick 20 and the second supporting brick 30 are arranged oppositely to form a cone-shaped space, and the closing door locking brick 40 is located in the cone-shaped space.

[0033] The shaft kiln refractory lining combination brick described in this embodiment is used to be installed at the door closing position on the shaft kiln refractory lining, wherein the door closing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com