Mechanical arm capable of clamping in rotary mode

A technology of a robotic arm and a rotating shaft, applied in the field of robotic arms, can solve problems such as uneconomical space utilization, and achieve the effect of high locking structure strength, simple structure, and increasing applicable scenarios.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

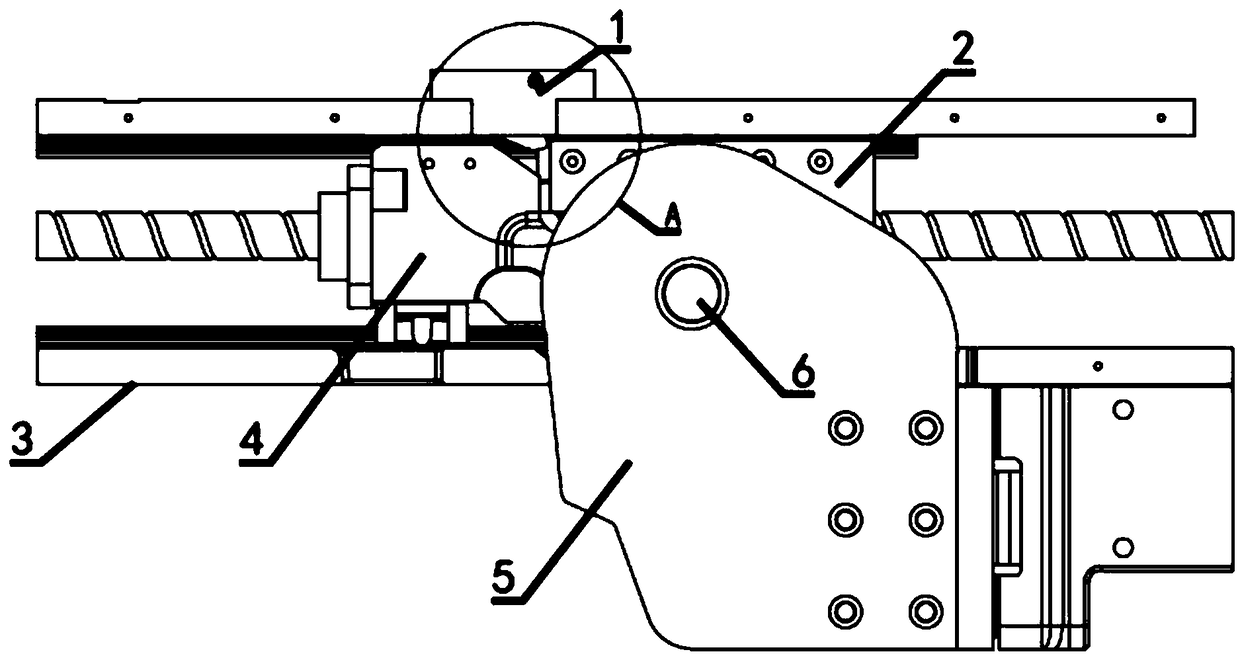

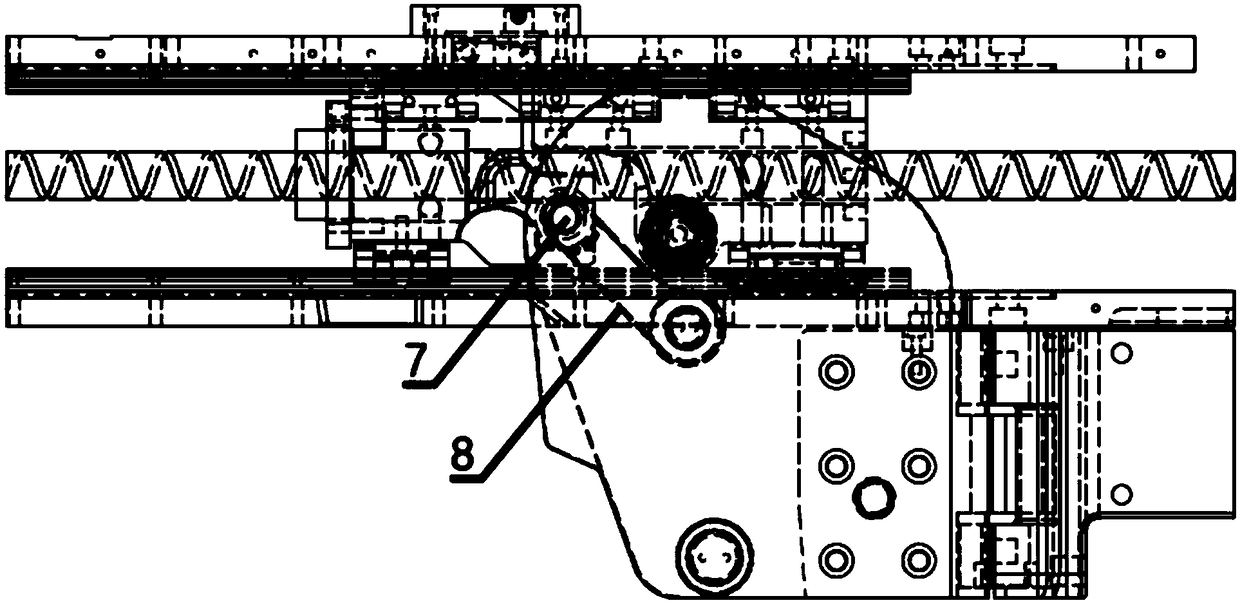

[0033] The invention provides a new type of rotatable clamping mechanical arm, including a lock pin device 1, a locking limit block 2, a frame 3, a driving device 4, a mechanical arm body 5, a mechanical arm rotation shaft 6, and a drive connection shaft 7 and drive tie rod 8, see figure 1 and image 3 .

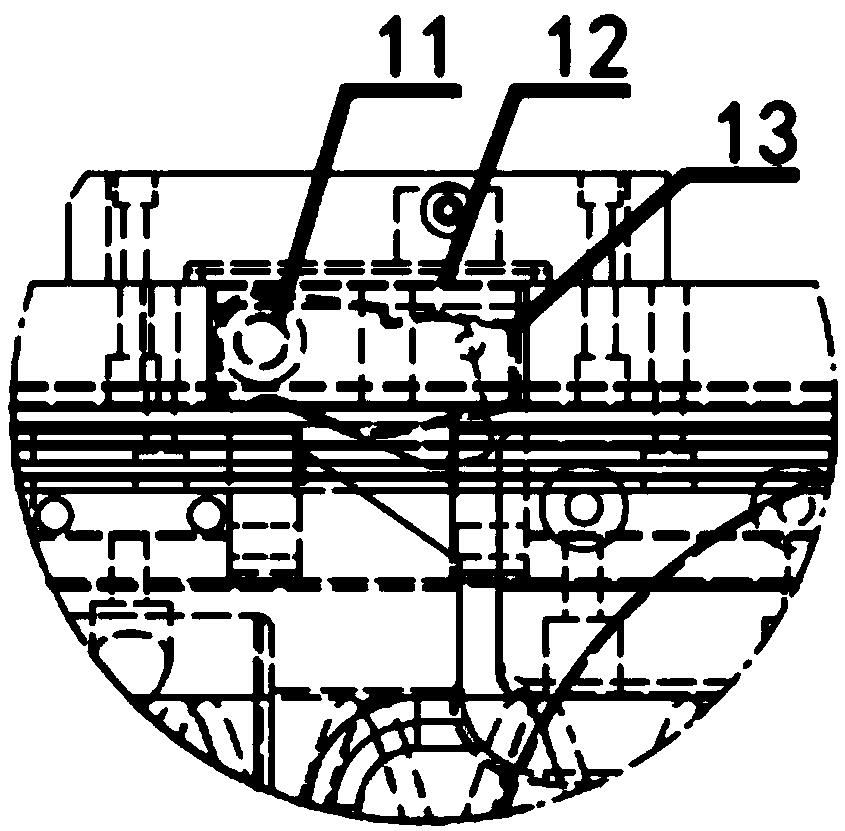

[0034] Described lock pin device 1 comprises lock pin rotating shaft 11, lock pin spring seat 12 and lock pin 13 etc., see figure 2 .

[0035] Described driving device 4 comprises leading screw 41, nut seat 42, driving block 43 etc., see Figure 4 .

[0036] The manipulator body 5 includes a clamping arm body 51, an upper connecting plate 52 of the mechanical arm, an upper connecting plate thrust column 53, a lower connecting plate thrust column 54, a lower connecting plate 55 of the mechanical arm, etc., see Figure 4 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com