gear processing device

A processing device and gear technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency and complicated procedures, and achieve the effects of simplifying processing procedures, improving processing efficiency, and eliminating detection steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

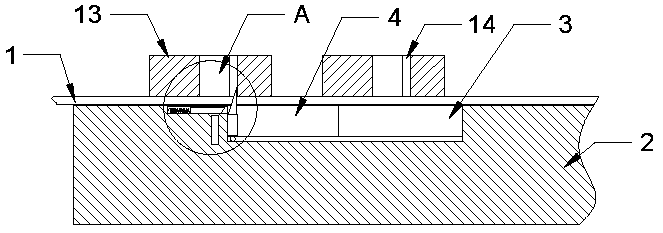

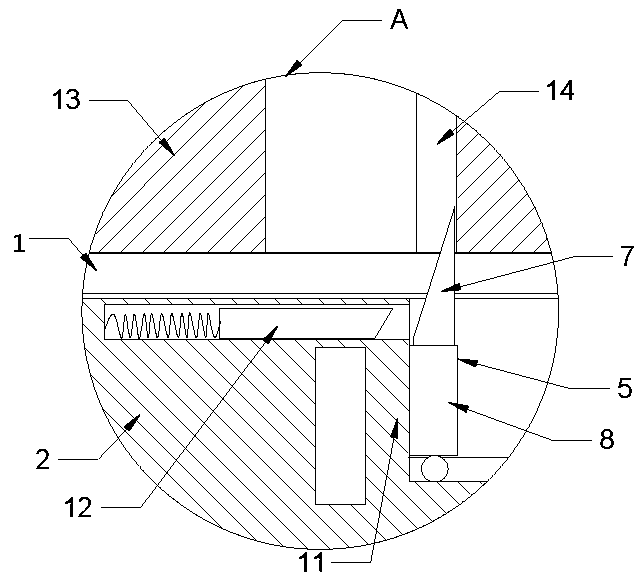

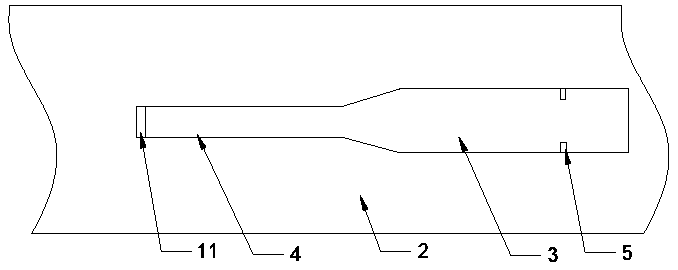

[0018] The reference signs in the drawings of the description include: conveyor belt 1, processing table 2, free passage 3, guide passage 4, telescopic rod 5, support plate 6, adjustment rod 7, limit cylinder 8, pillar 9, tension spring 10, stop Block 11, drive plate 12, gear 13, spline groove 14, transmission channel 15.

[0019] The embodiment is basically as attached figure 1 Shown: gear processing device, including transmission mechanism and adjustment mechanism,

[0020] as attached image 3 , Figure 4 As shown, the transmission mechanism includes a processing table 2 and a conveyor belt 1 installed on the processing table 2. A transmission channel 15 is provided on the conveyor belt 1. The width of the transmission channel 15 is larger than the inner diameter of the gear 13. A horizontal channel is opened on the processing table 2 and is located directly below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com