A rotary flame welding machine

A rotary type, flame technology, applied in gas flame welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of non-adjustment and single, achieve the effect of flexible adjustment, wide application range, easy disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

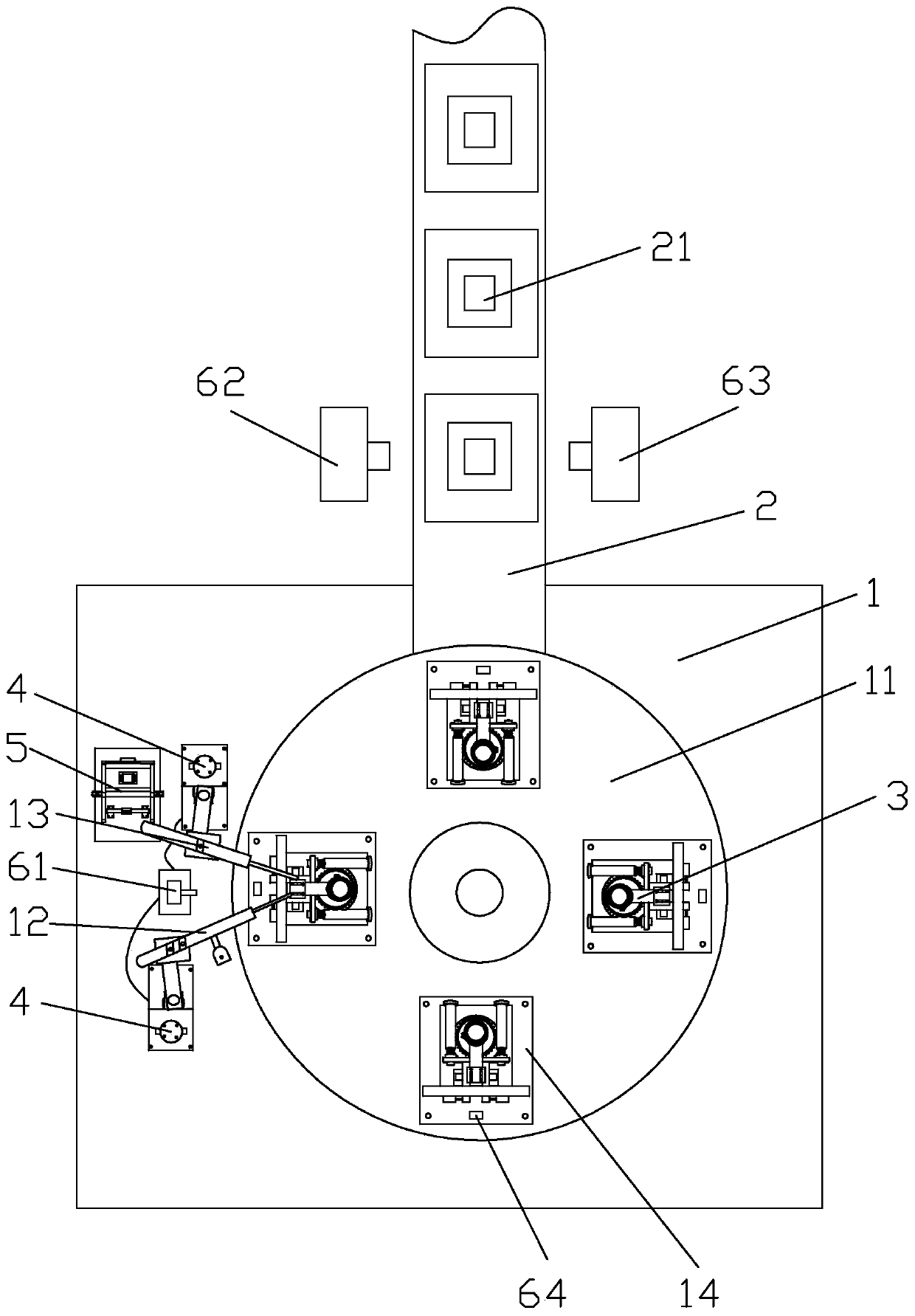

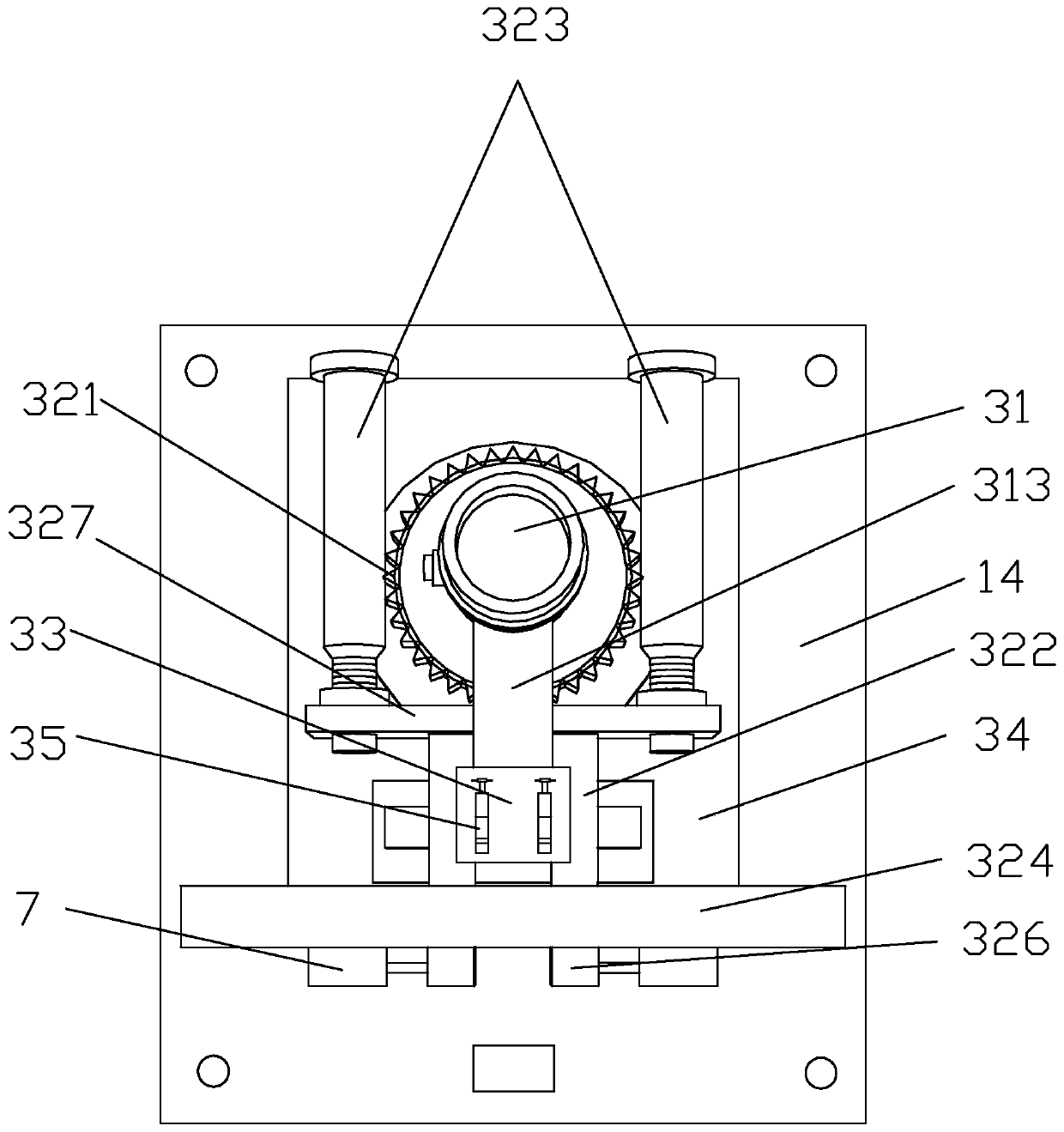

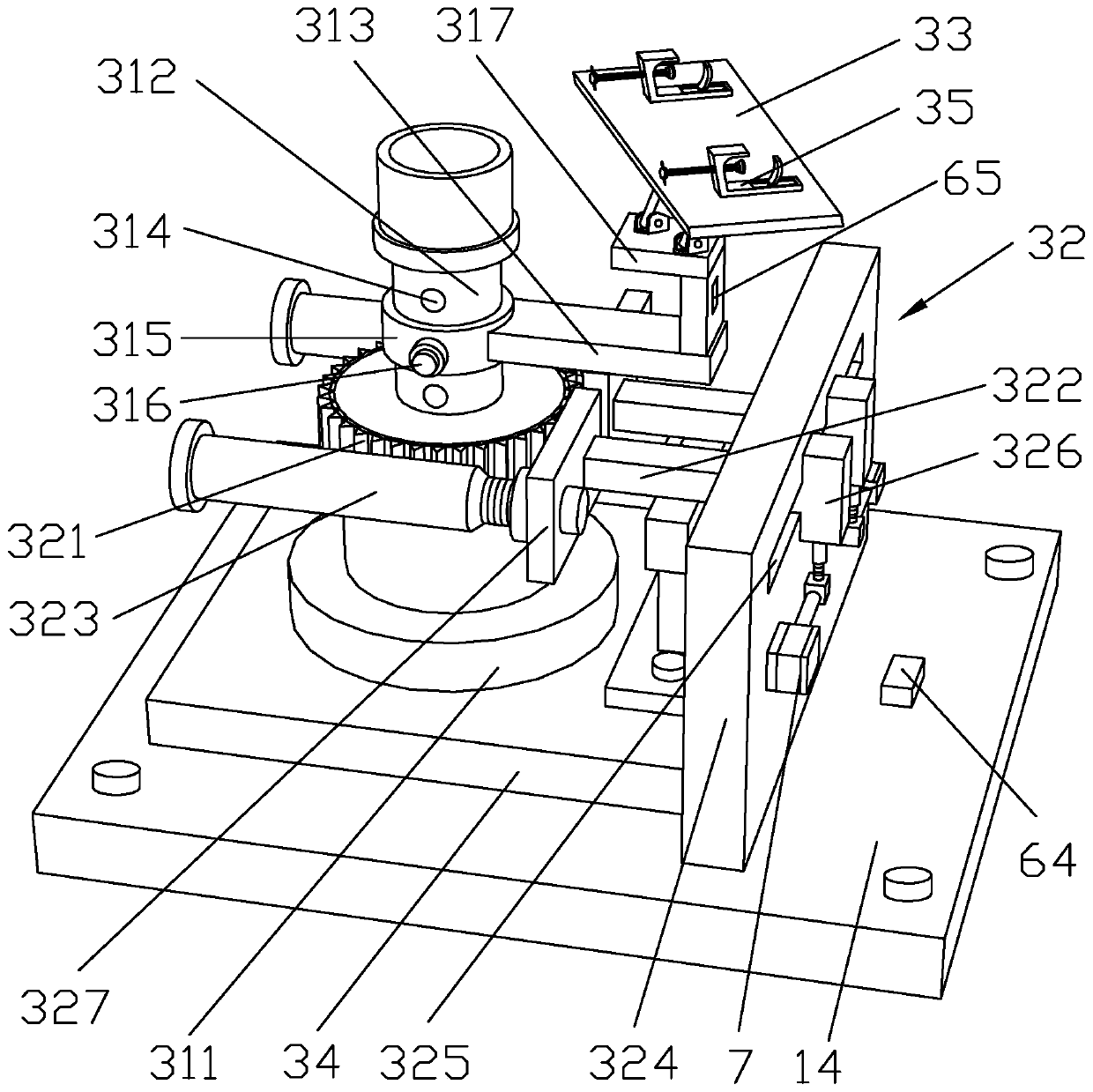

[0032] Such as Figure 1-9 As shown, it is a rotary table flame welding machine of the present invention, which includes a workbench 1 and a conveying track 2. The workbench 1 is provided with a rotary table 11, a welding torch 12, a wire feeding gun 13 and an induction device, and the output of the conveying track 2 is The end is correspondingly connected with the rotary table 11, and the rotary table 11 is driven to rotate by the first driver. The upper circumference of the rotary table 11 is distributed with processing stations 14, and the processing station 14 is provided with processing fixtures 3 and induction switches. The processing fixture 3 includes a rotating device 31, a locking device 32 and a support plate 33. Both the rotating device 31 and the locking device 32 are fixed on the processing station 14 through the base 34. The rotating device 31 is driven to rotate by the second driver, and the locking device 32 to lock the rotating device 31 , the supporting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com