Manufacturing method of motorcycle accessory

A manufacturing method and motorcycle technology, applied in the field of pipe fittings manufacturing, can solve problems such as easy surface wear, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

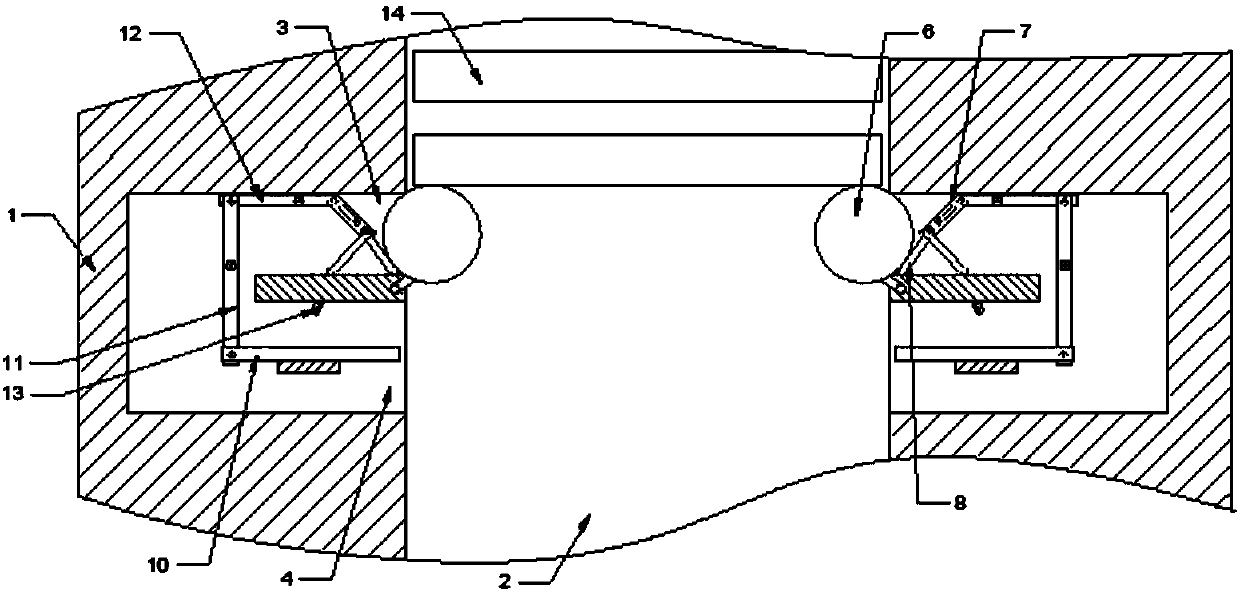

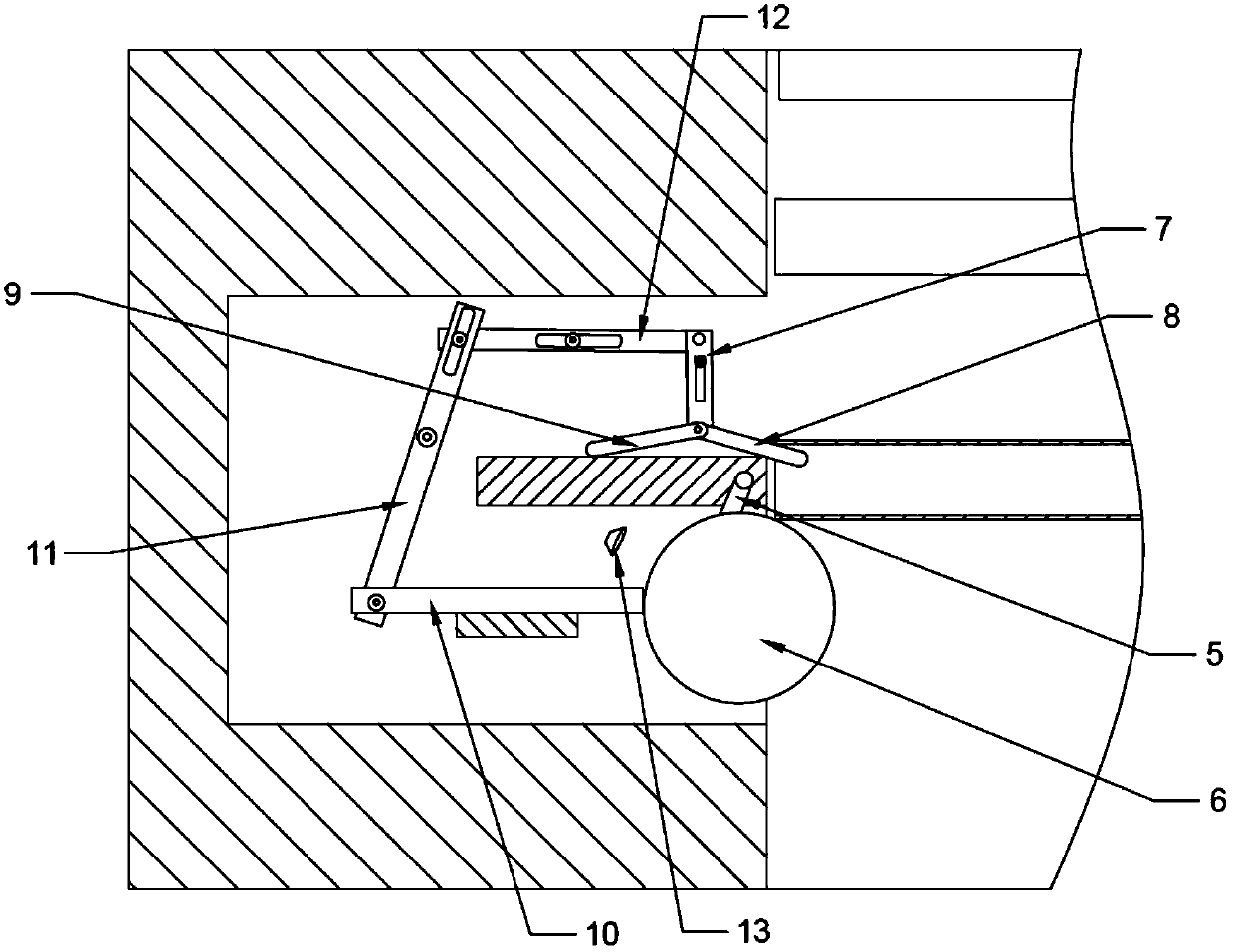

[0019] The reference signs in the drawings of the description include: frame 1, transmission channel 2, first control channel 3, second control channel 4, swing shaft 5, control ball 6, slide bar 7, first connecting rod 8, second Connecting rod 9, drive rod 10, swing rod 11, control rod 12, sucker 13, pipe fitting 14.

[0020] The embodiment is basically as attached figure 1 , figure 2 Shown: the manufacturing method of motorcycle accessory, comprises the following steps:

[0021] Step 1: prepare a frame, set the transmission channel 2 along the vertical direction of the frame, the width of the transmission channel 2 is slightly larger than the length of the pipe fitting 14, and the two sides of the transmission channel 2 are respectively equipped with control units, the control unit includes two horizontal The first control channel 3 and the second control channel 4 are set, the cross-sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com