Wall pouring formwork

A formwork and wall technology, applied in the direction of formwork/formwork/work frame, construction, formwork/formwork/work frame connectors, etc., can solve problems such as difficult control of level, rotten roots, and low hardness , to achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

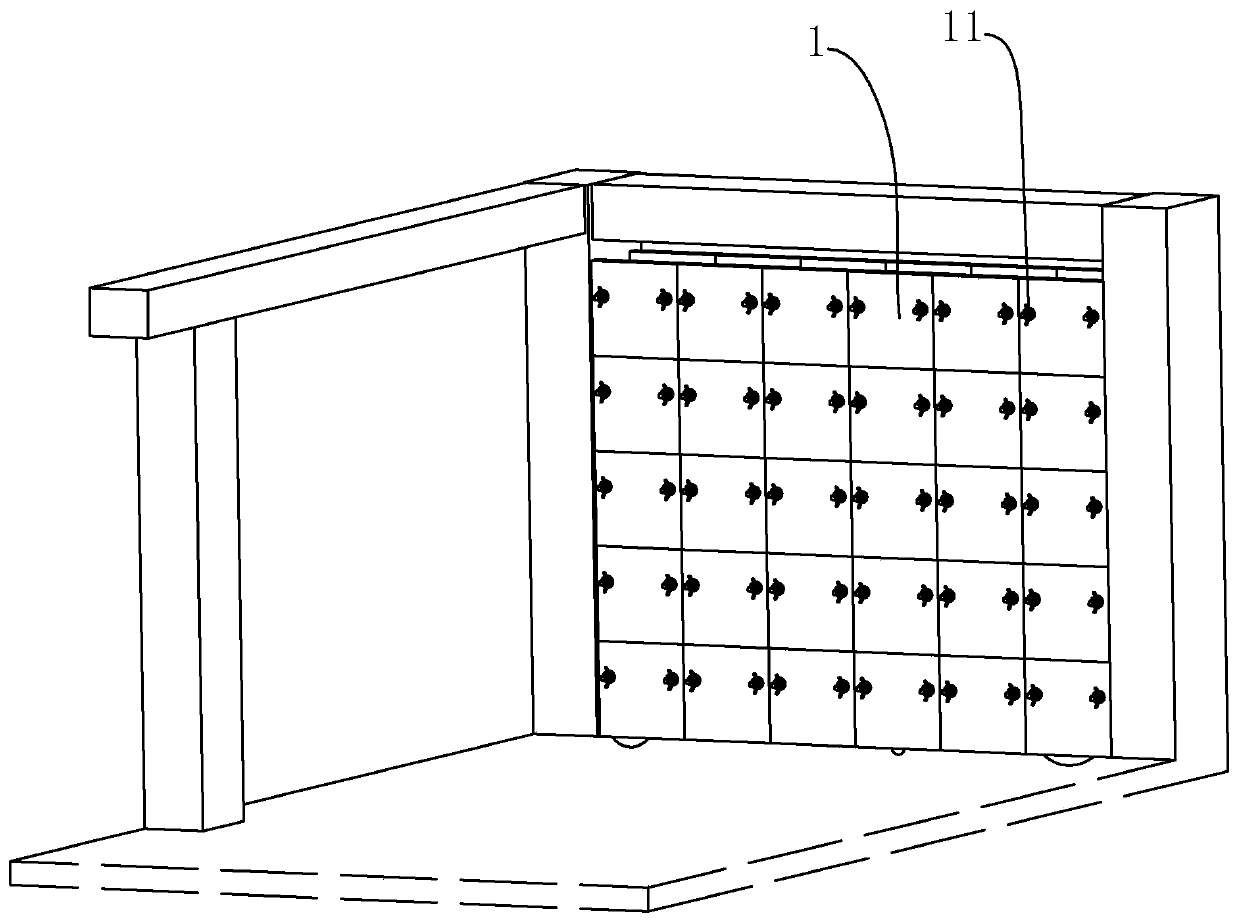

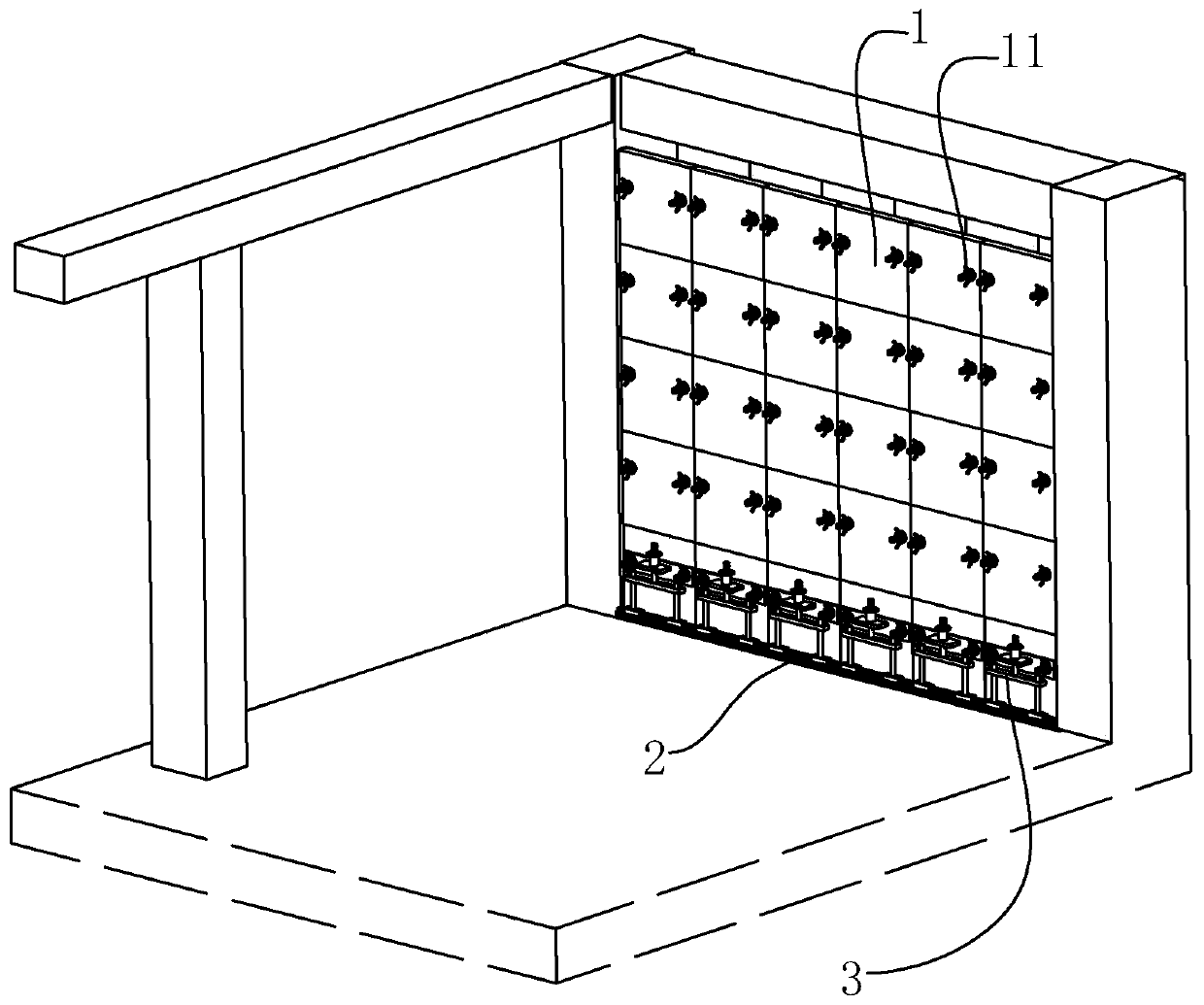

[0034] Embodiment 1: body of wall pouring formwork, as figure 2 As shown, when pouring the wall, the preset template 1 is first arranged on the floor, and the pull bolts 11 are limited and fastened. In order to reduce the occurrence of rotten roots when pouring the body of wall, a sealing strip 2 made of flexible materials such as silica gel and sponge is installed at the bottom of the template 1 . The sealing strip 2 has good elastic deformation ability, and it compensates for the unevenness of the ground through its own deformation, blocks the gap between the formwork 1 and the ground, prevents the outflow of concrete slurry, and reduces the phenomenon of root rot when pouring the wall appear.

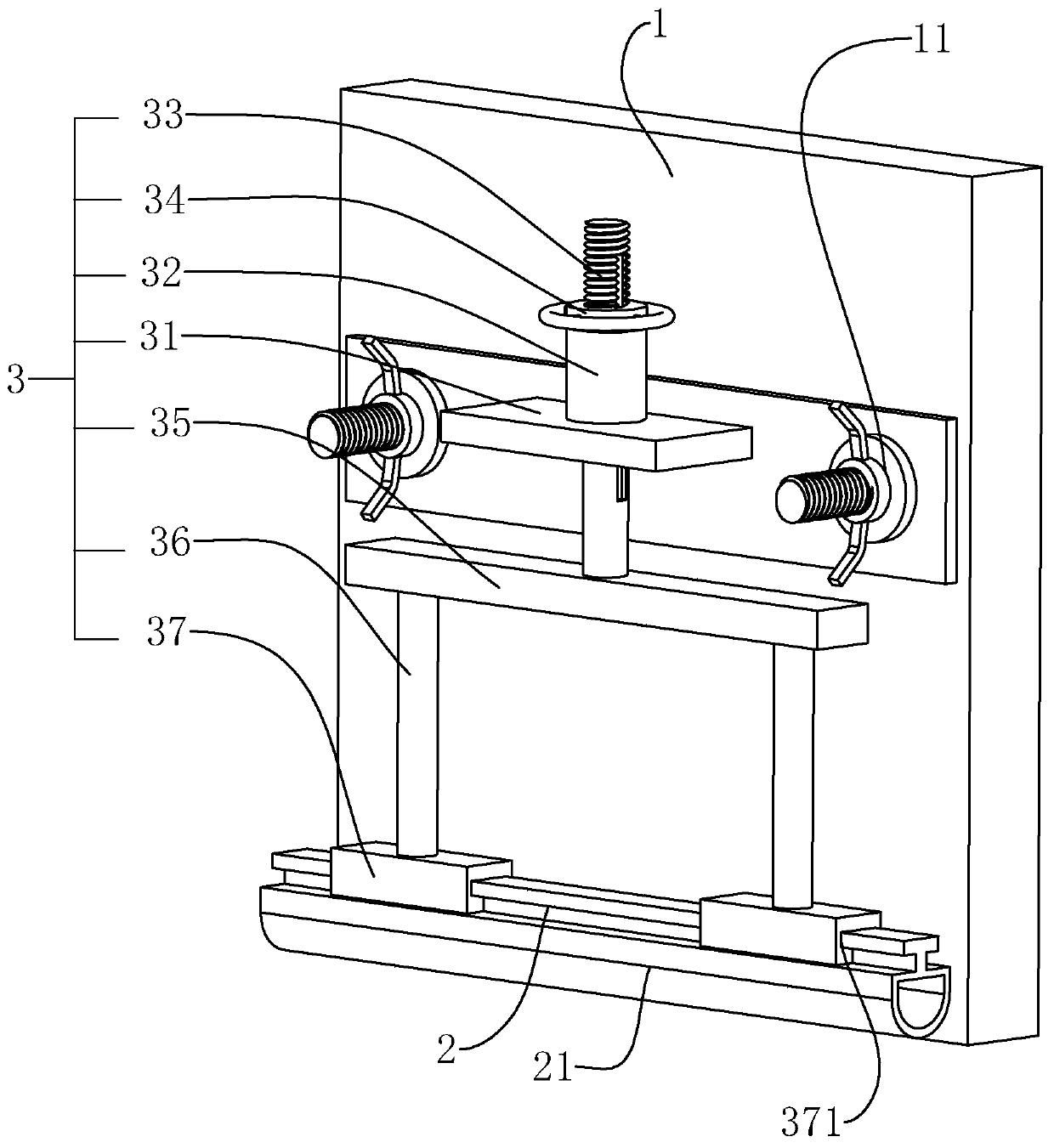

[0035] In actual use, it is cumbersome to select a specific number of templates 1 each time to install the sealing strips. Therefore, a pressing assembly 3 for installing and compressing the sealing strips 2 is provided on the template 1 .

[0036] Such as image 3 , Figure 4 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com