A pneumatically driven flexible support control device

A technology of flexible support and pneumatic transmission, applied in the direction of positioning device, clamping device, support, etc., can solve the problems of complex structure of flexible support device, unfavorable multi-point support and rigidity of the supported surface, so as to avoid instability of vacuum adsorption and improve Rigidity, new structure and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

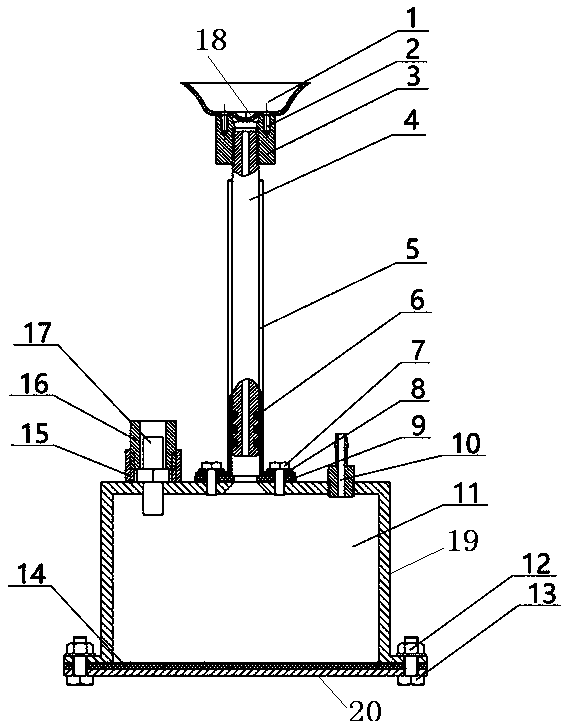

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] Such as Figure 1-3 shown.

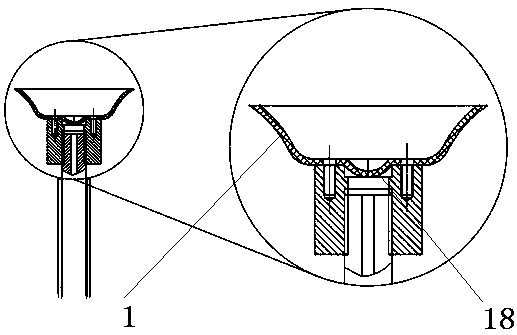

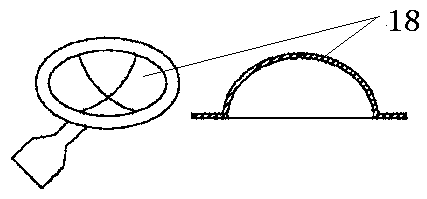

[0022] A pneumatically driven flexible support control device, which includes a vacuum chuck 1 and a hollow piston rod 4, the center of the vacuum chuck 1 is provided with a diaphragm 18 with an opening, the diaphragm 18 is hemispherical, and the opening at the center of the hemisphere It is in the shape of "ten", such as figure 2 , 3 , the vacuum chuck 1 is fixed on the connector 3 through four slotted countersunk screws 2, and one end of the hollow piston rod 4 is sealed and fixed in the connector 3 so as to drive the vacuum chuck 1 to move to the desired location through the connector 3 Adsorb on the workpiece and leave the workpiece after processing. The cavity of the hollow piston rod 4 is connected to the cavity of the vacuum chuck 1 through the opening and closing of the diaphragm 18. The lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com