Traction buffer device for locomotive

A traction buffer, locomotive technology, applied in traction devices, transportation and packaging, railway car body parts, etc., can solve the problems of elastomer buffer cake damage and high maintenance costs of buffer devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A locomotive traction buffer device provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

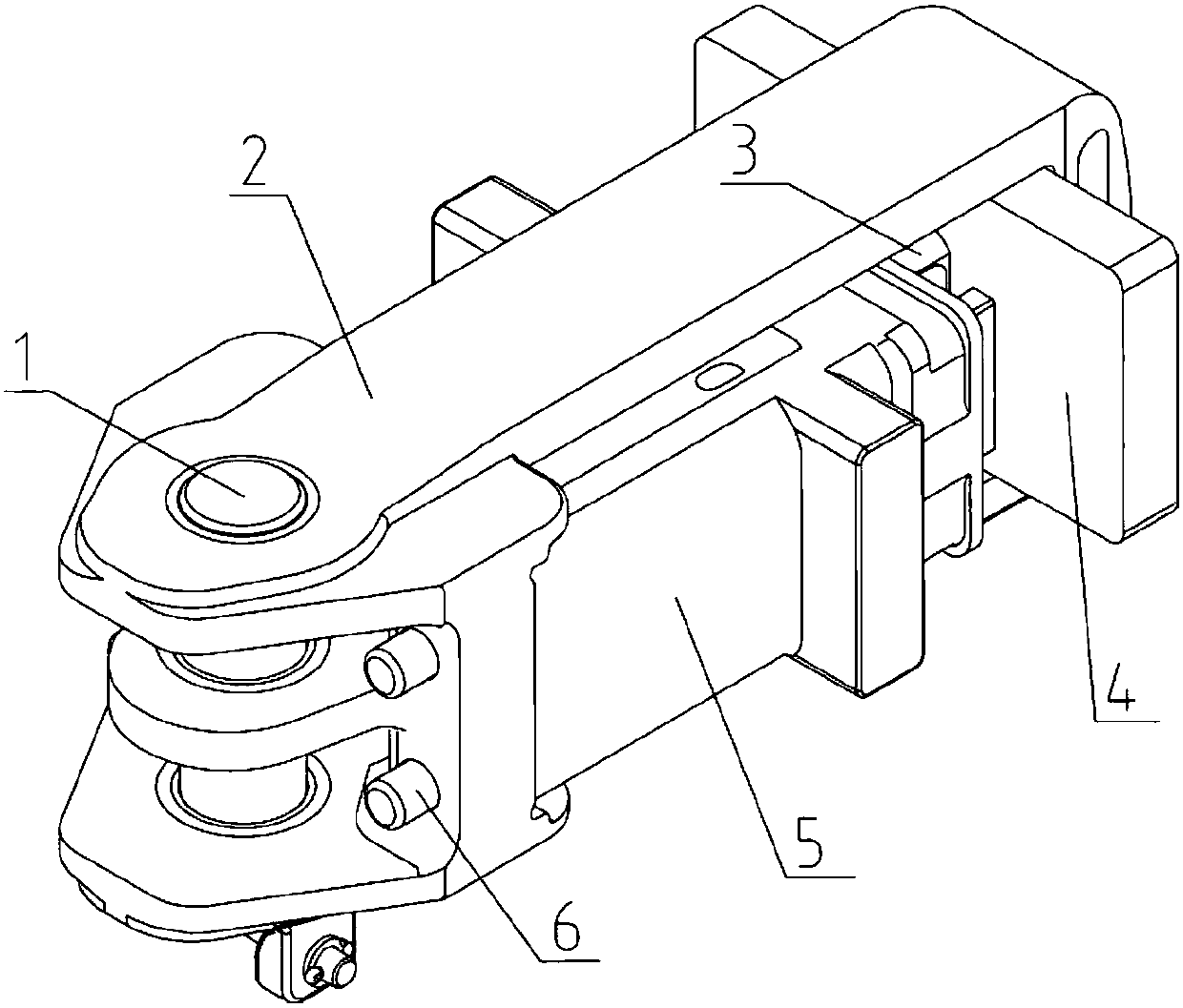

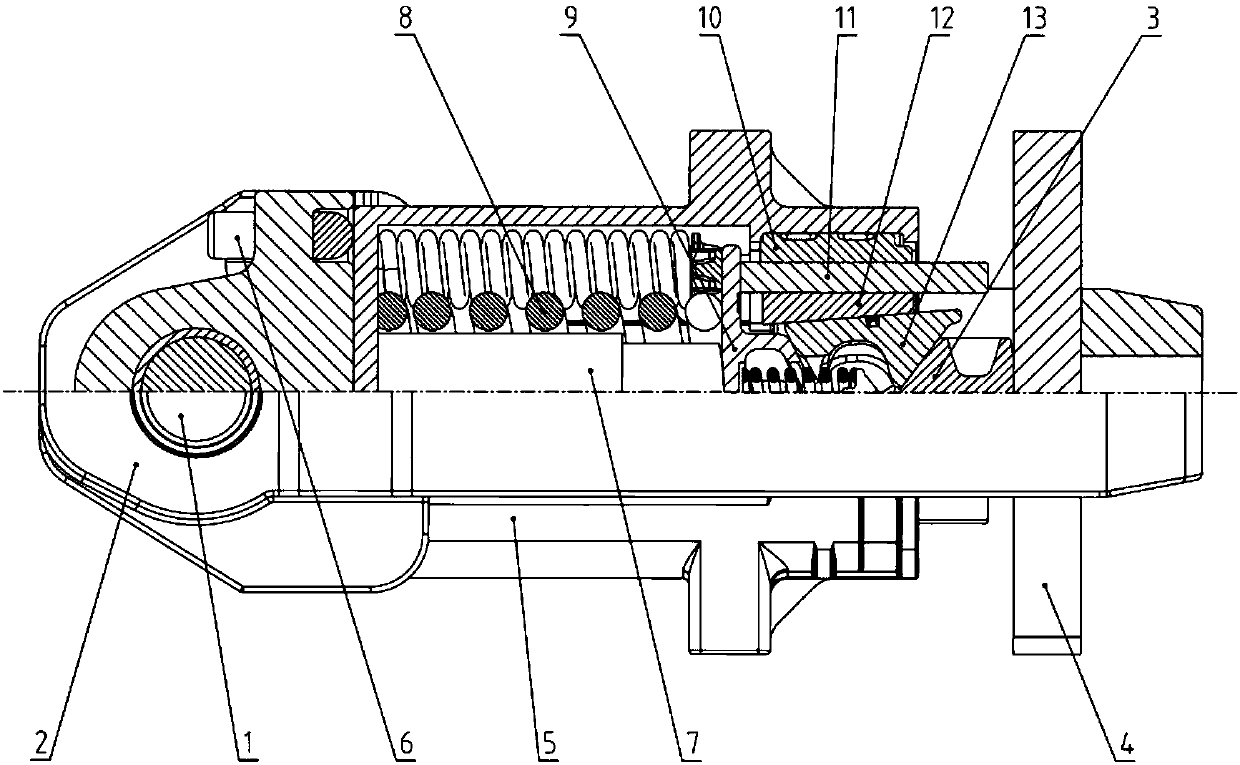

[0021] figure 1 and figure 2 Shown is a traction buffer device for a locomotive, comprising a coupler pin 1, a coupler frame 2, a center wedge 3, a rear follower plate 4, a buffer box 5, a buffer plug 6 and an elastic cement core 7, the coupler The front end of the frame 2 is connected to the coupler pin 1, the middle part of the coupler frame 2 fixes the buffer box 5 through the buffer plug 6, the center wedge 3 is arranged at the rear end of the buffer box 5, and the rear slave plate 4 is arranged at the rear end of the center wedge 3, The elastic mastic core 7 is arranged inside the buffer box 5 .

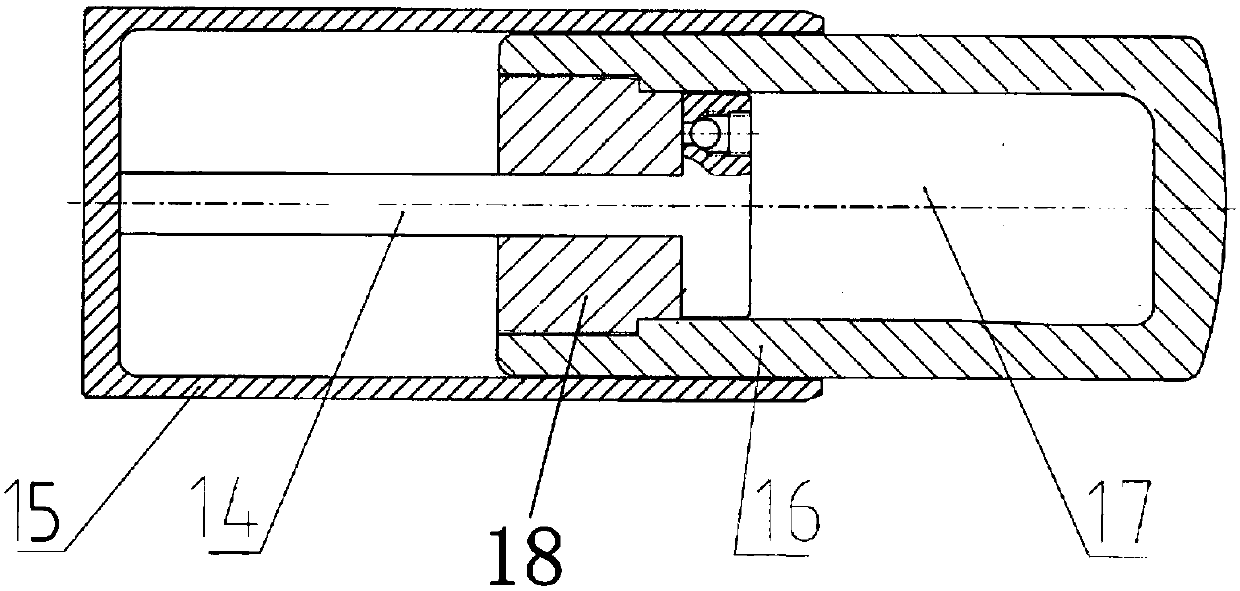

[0022] Inside the buffer box 5, a spring assembly 8 is arranged on the upper part; an elastic mastic core body 7 is arranged on the lower part, and a spring seat 9 is arranged on the spring ass...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap