Disc brake lock structure

A technology for disc brake locks and lock cores, which is applied to bicycle accessories, devices to prevent theft of bicycles, transportation and packaging, etc. Convenient, good anti-theft effect, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Regarding the technical means adopted by the present invention in order to achieve the above-mentioned use purposes and effects, a preferred and feasible embodiment is presented and shown in the drawings. The details are as follows:

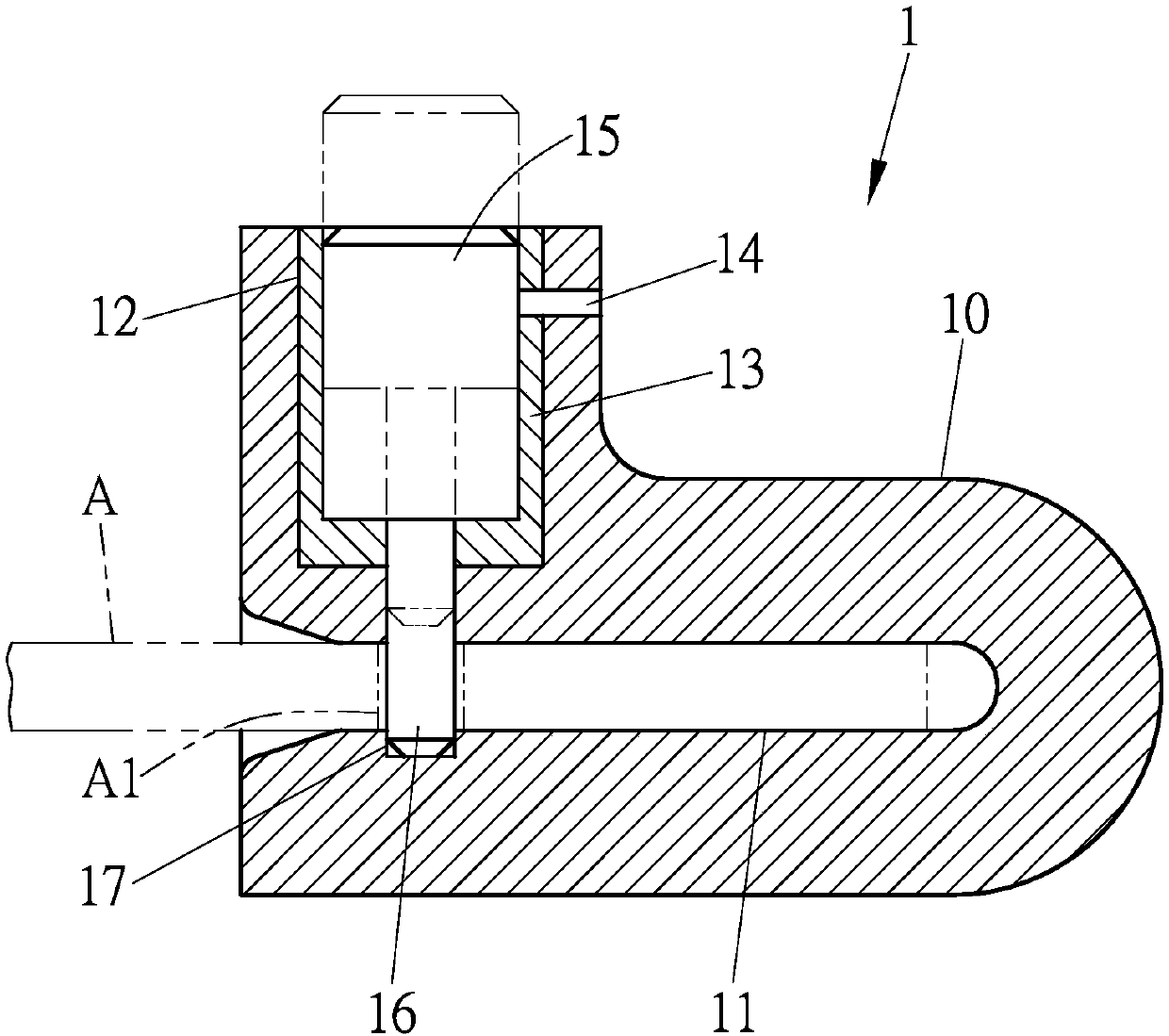

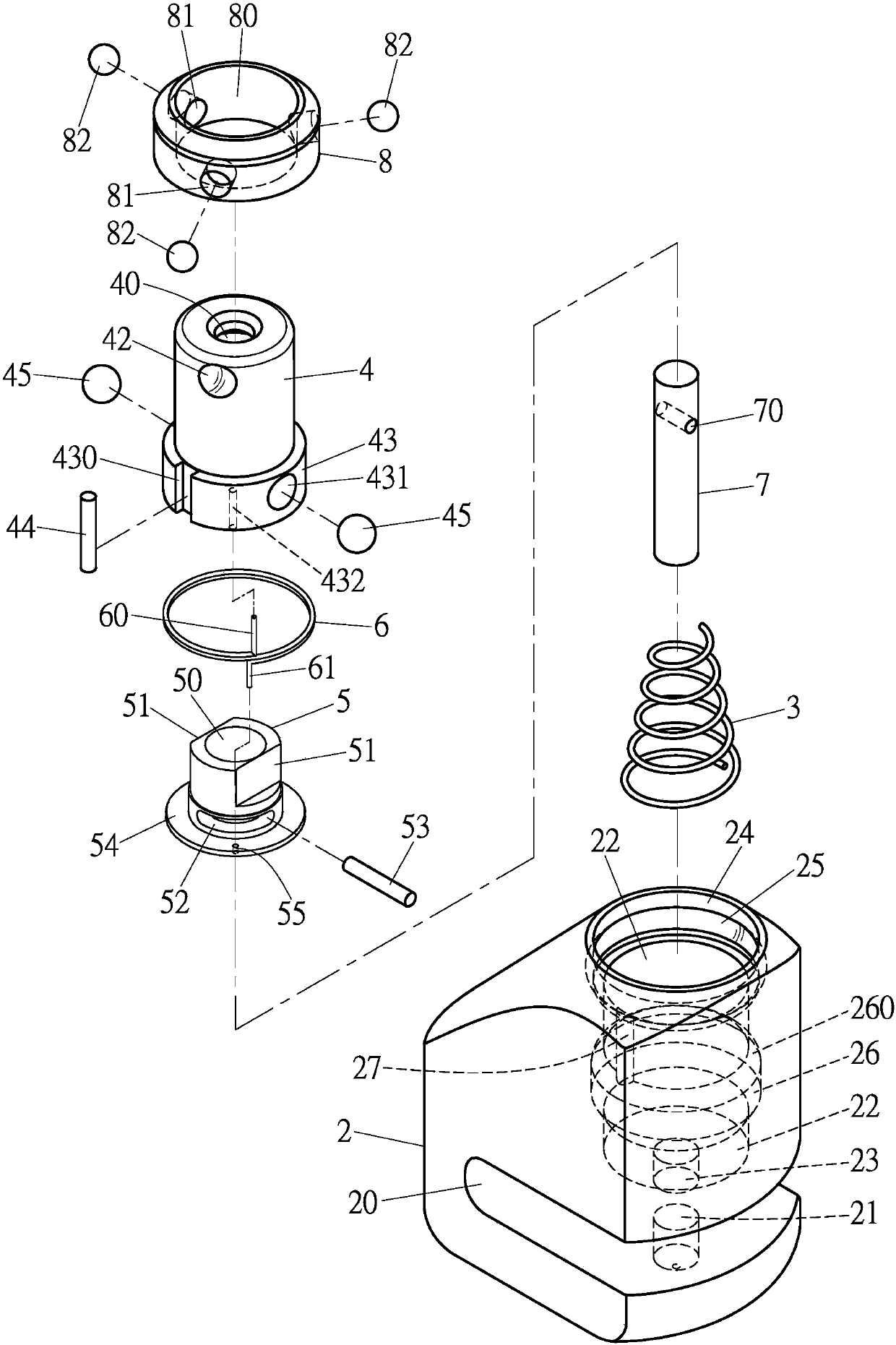

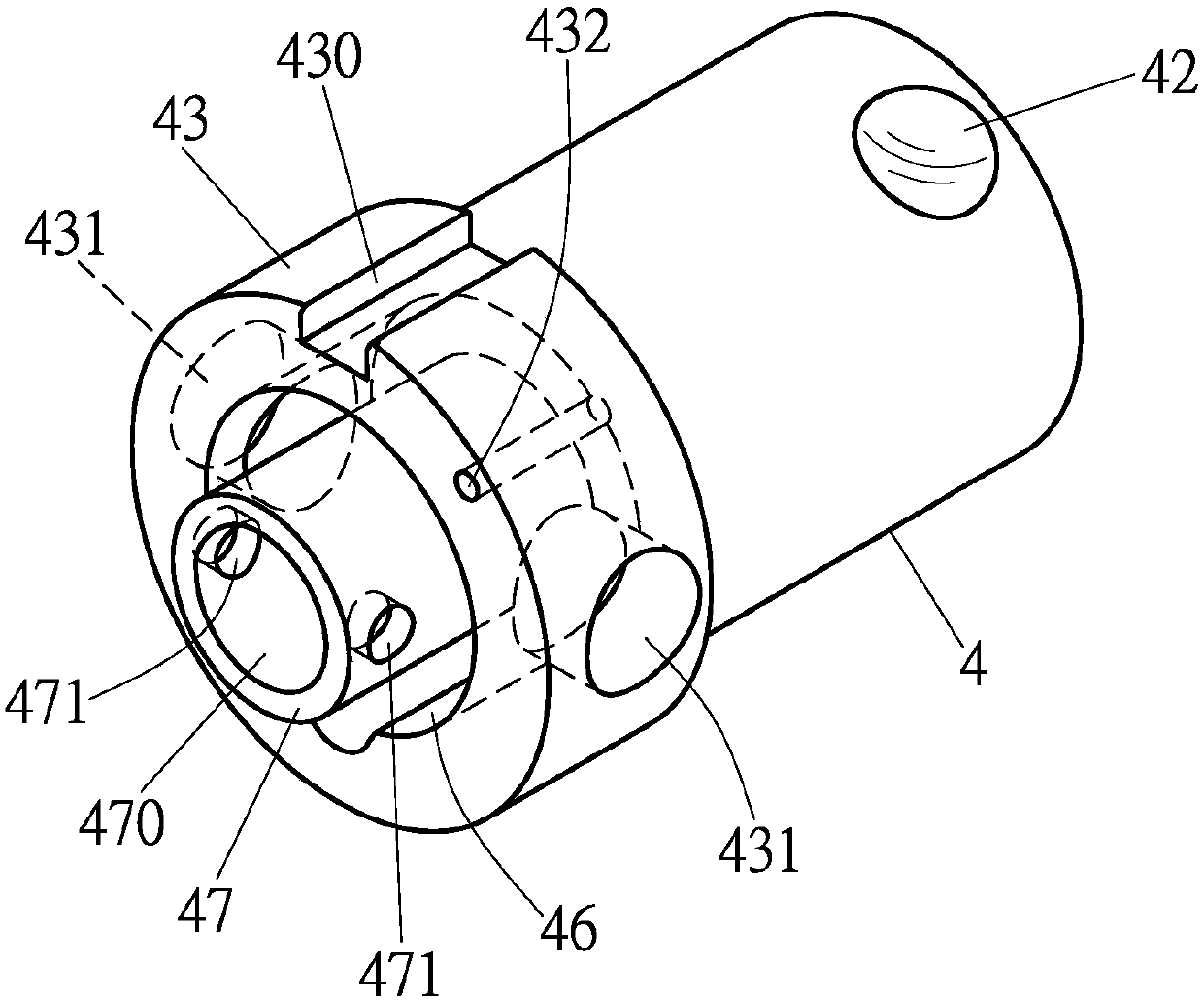

[0020] For examples of the present invention, please refer to figure 2 , image 3 , Figure 4 As shown, there is mainly a body 2 provided with a notch 20. The bottom of the cut 20 is provided with an insertion groove 21. The body 2 is provided with a chamber 22, and the bottom of the chamber 22 is provided with a communicating To the perforation 23 of the slot 20, the perforation 23 corresponds to the insertion groove 21, the upper part of the chamber 22 is provided with a fixing groove 24, the fixing groove 24 is provided with a ring groove 25, and the chamber 22 is provided with There is a positioning groove 26, the diameter of the positioning groove 26 is larger than the diameter of the chamber 22, and the upper part of the positioning gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com