A water-bound gravel paving device for road construction

A technology for road construction and gravel, which is applied in the direction of roads, roads, road repairs, etc., and can solve the problems of low paving efficiency and road paving equipment that cannot fully meet the paving requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

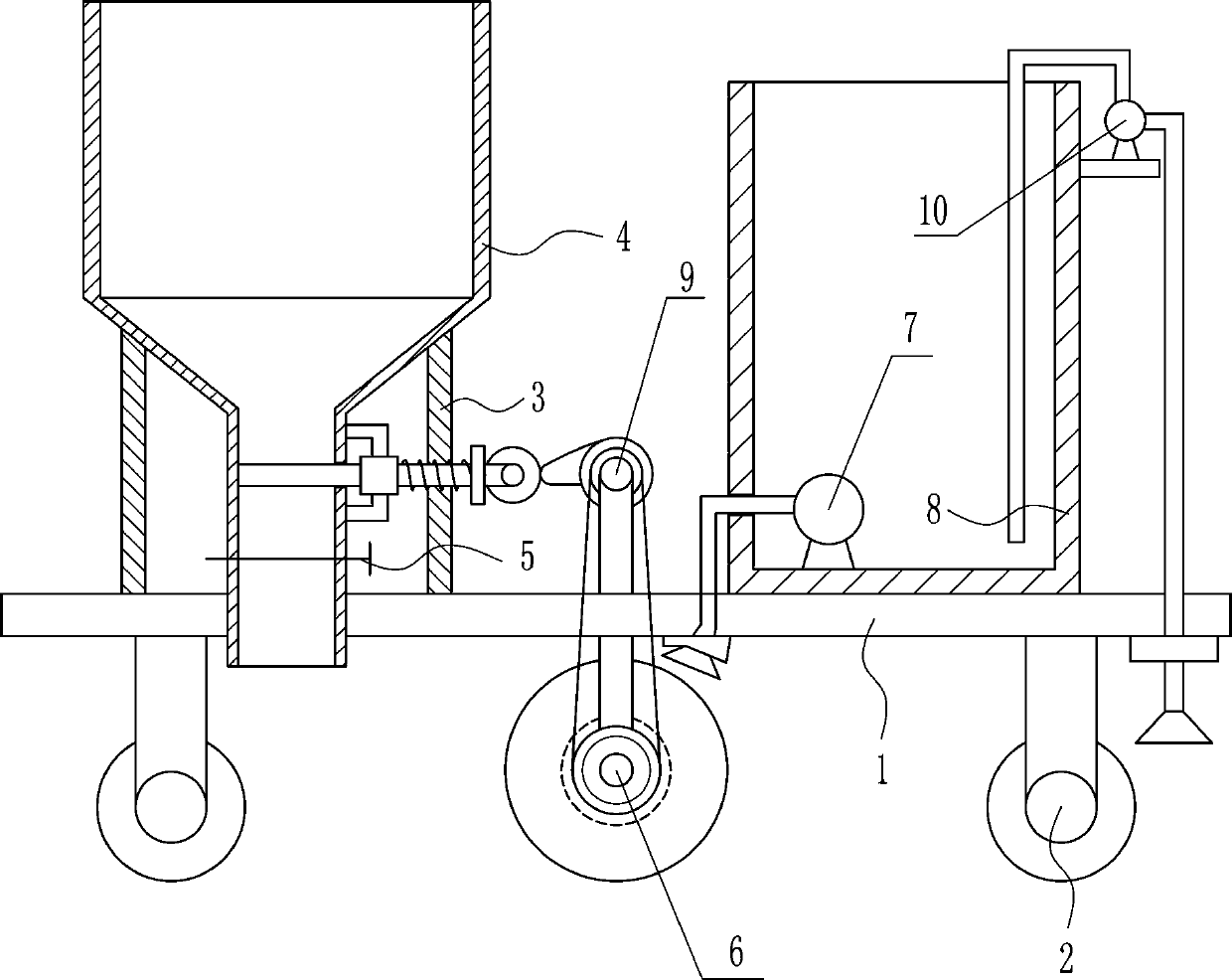

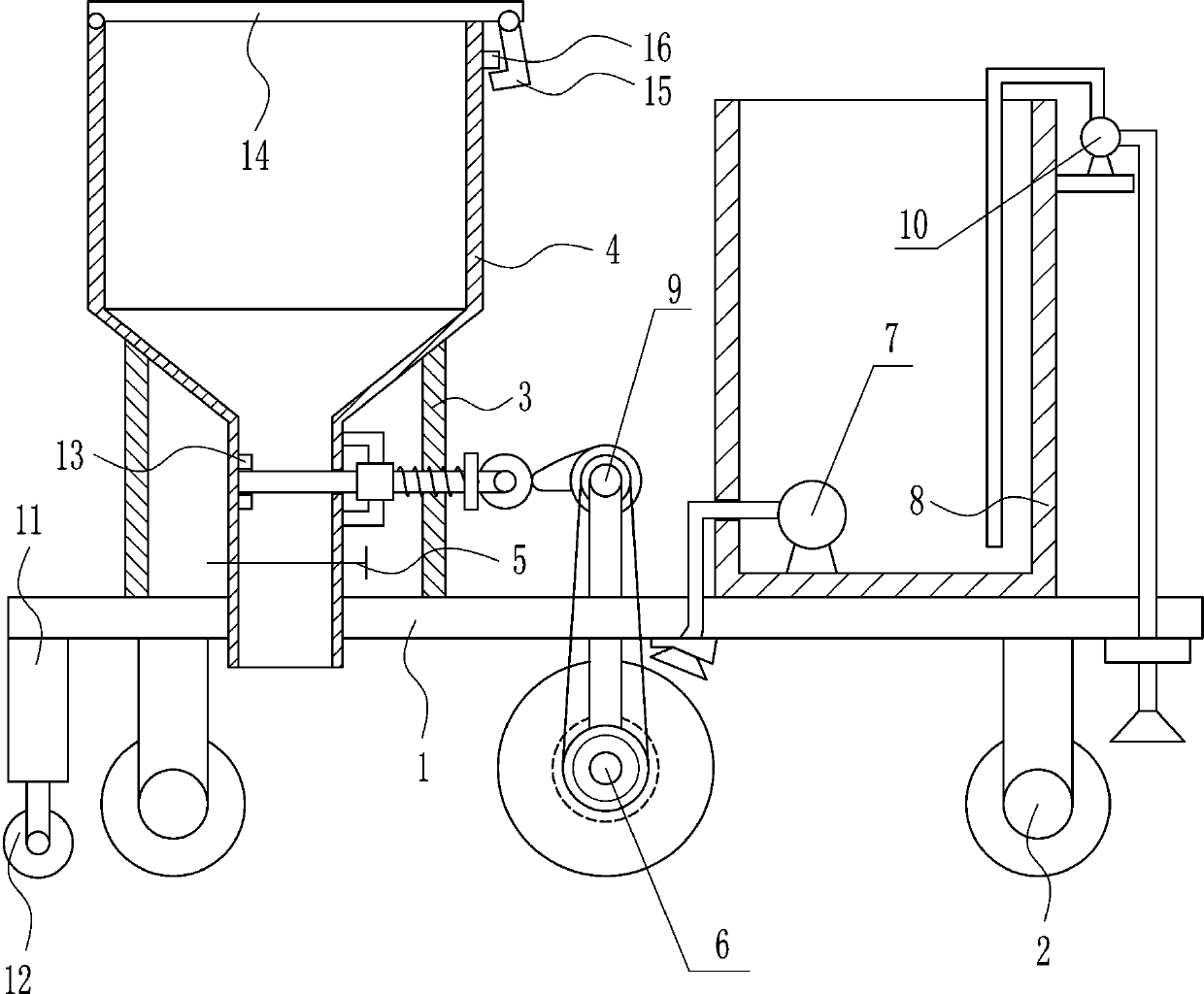

[0037] A road construction water-bound gravel paving device, such as Figure 1-7 As shown, it includes a base plate 1, wheels 2, support rods 3, box body 4, valve 5, compacting mechanism 6, water knot treatment mechanism 7 and water tank 8, the bottom of the base plate 1 is provided with wheels 2, and the top of the base plate 1 is vertical Connected with a support rod 3, the top of the support rod 3 is provided with a box body 4, the discharge position of the box body 4 is located at the bottom of the bottom plate 1, and a water tank 8 is installed on the right side of the top of the bottom plate 1, and a water knot treatment mechanism is installed in the water tank 8 7. A compacting mechanism 6 is installed in the middle of the bottom of the bottom plate 1 .

Embodiment 2

[0039] A road construction water-bound gravel paving device, such as Figure 1-7 As shown, it includes a base plate 1, wheels 2, support rods 3, box body 4, valve 5, compacting mechanism 6, water knot treatment mechanism 7 and water tank 8, the bottom of the base plate 1 is provided with wheels 2, and the top of the base plate 1 is vertical Connected with a support rod 3, the top of the support rod 3 is provided with a box body 4, the discharge position of the box body 4 is located at the bottom of the bottom plate 1, and a water tank 8 is installed on the right side of the top of the bottom plate 1, and a water knot treatment mechanism is installed in the water tank 8 7. A compacting mechanism 6 is installed in the middle of the bottom of the bottom plate 1 .

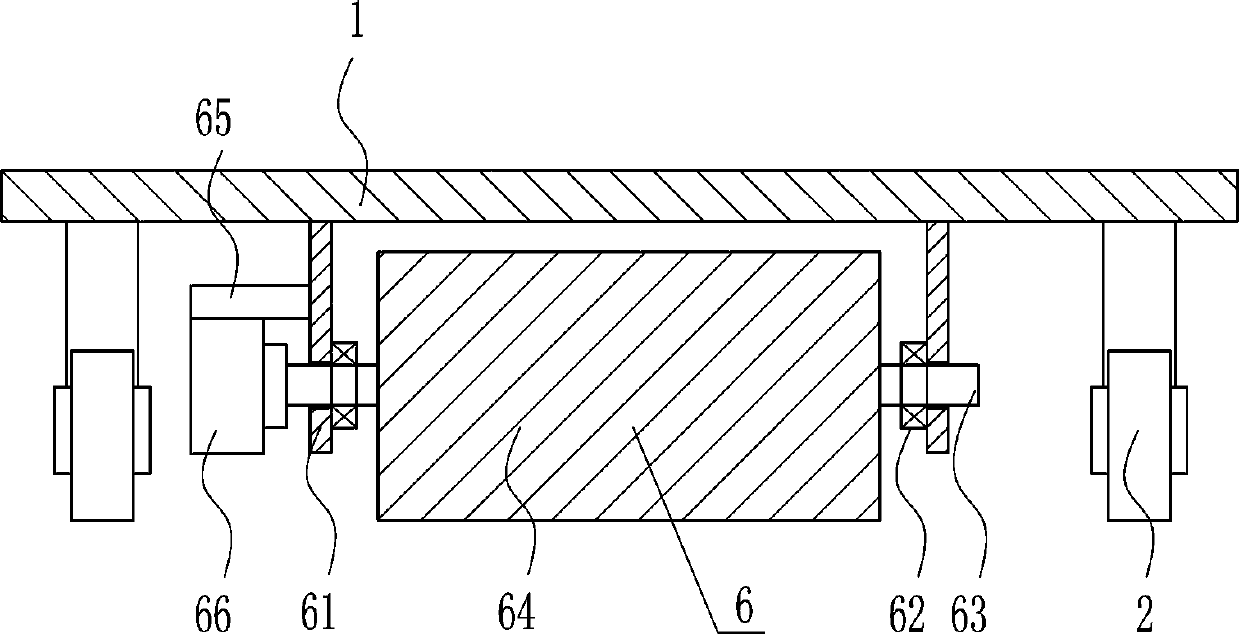

[0040] The compacting mechanism 6 includes a first pole 61, a bearing seat 62, a rotating rod 63, a cylinder 64, a base 65, and a motor 66. The front and rear positions in the middle of the bottom of the base plate 1 a...

Embodiment 3

[0042] A road construction water-bound gravel paving device, such as Figure 1-7 As shown, it includes a base plate 1, wheels 2, support rods 3, box body 4, valve 5, compacting mechanism 6, water knot treatment mechanism 7 and water tank 8, the bottom of the base plate 1 is provided with wheels 2, and the top of the base plate 1 is vertical Connected with a support rod 3, the top of the support rod 3 is provided with a box body 4, the discharge position of the box body 4 is located at the bottom of the bottom plate 1, and a water tank 8 is installed on the right side of the top of the bottom plate 1, and a water knot treatment mechanism is installed in the water tank 8 7. A compacting mechanism 6 is installed in the middle of the bottom of the bottom plate 1 .

[0043] The compacting mechanism 6 includes a first pole 61, a bearing seat 62, a rotating rod 63, a cylinder 64, a base 65, and a motor 66. The front and rear positions in the middle of the bottom of the base plate 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com