A precision thread pressure ring torque-pretightening force mapping relationship measurement device

A precision thread and measuring device technology, applied to measuring devices, force/torque/work measuring instruments, measuring torque/torsion force during tightening, etc., can solve problems such as unsuitable for engineering applications, unsuitable for thread pressure rings, complicated operations, etc. , to achieve the effects of concise and clear conversion process, avoiding measurement errors and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0031] The present invention provides a precision threaded pressure ring connection torque-pretightening force mapping relationship measuring device, and the technical solution for realizing the present invention is as follows:

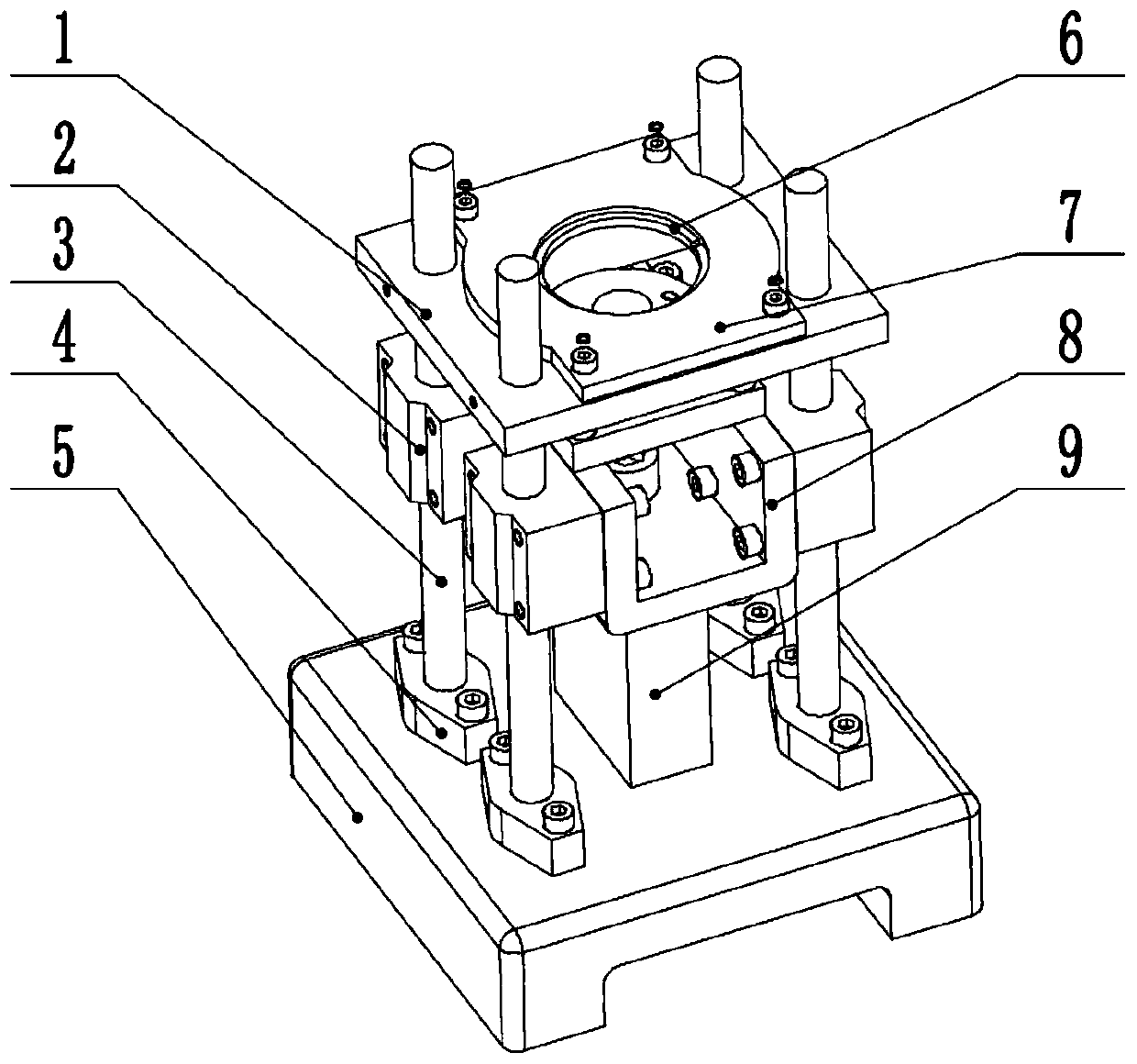

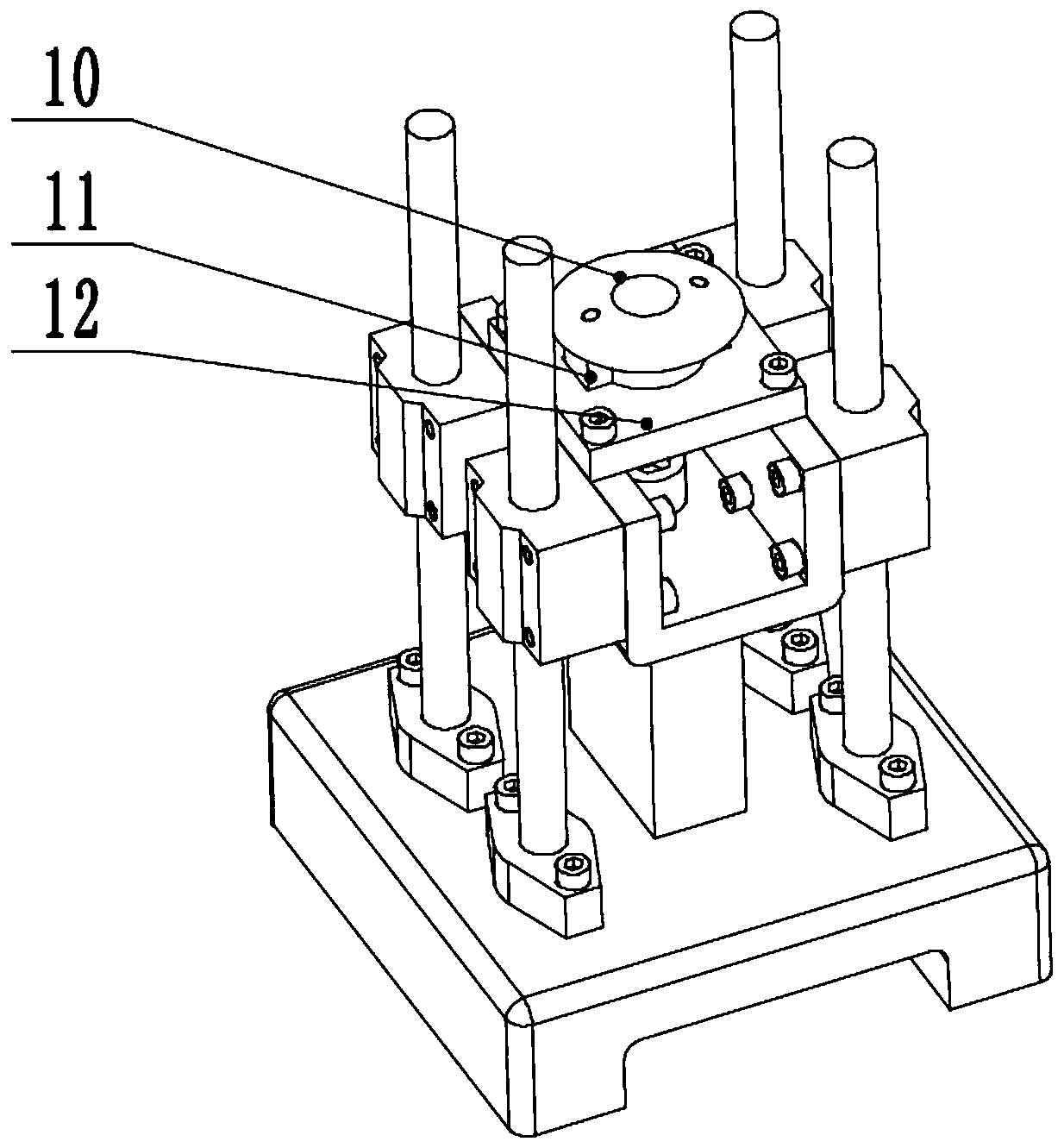

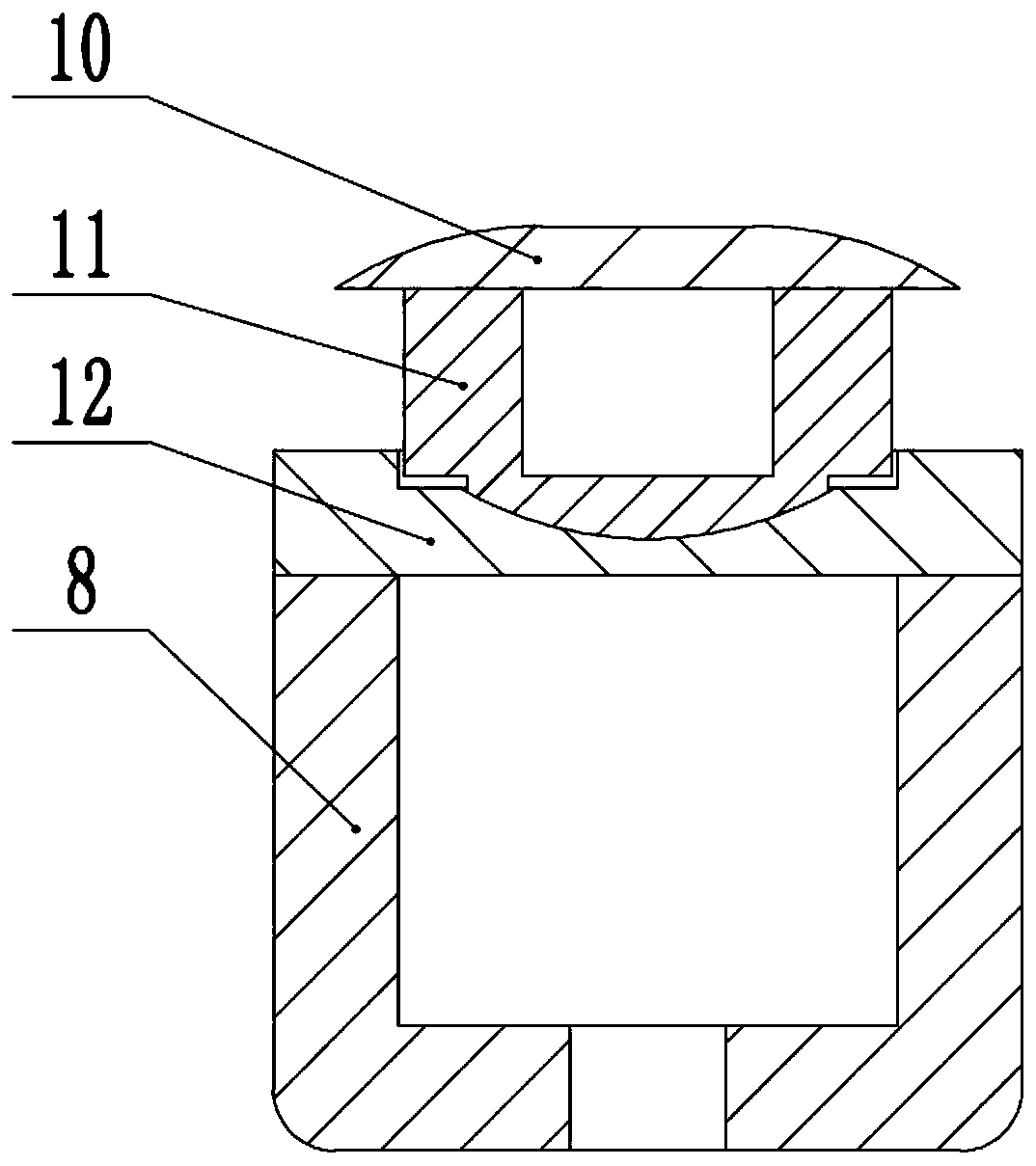

[0032] as attached figure 1 , 2 As shown, a measuring device for the connection torque-pretightening force of a precision threaded pressure ring includes: a torque measuring instrument, a special wrench for tightening a threaded pressure ring, an S-shaped high-precision sensor 9, an analog lens 10, and a replaceable threaded pressure ring nut assembly , a spherical contact connection assembly, a linear limit assembly, and a base 5;

[0033] The torque measuring instrument is connected with a special wrench for tightening the threaded pressure ring;

[0034] The lower end of the S-type high-precision sensor 9 is fixedly connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com