Measuring device and method suitable for lamination plate load-deformation mapping relation

A technology of mapping relationship and measuring device, applied in the direction of measuring device, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems that do not exist, and achieve the effect of concise and clear transformation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

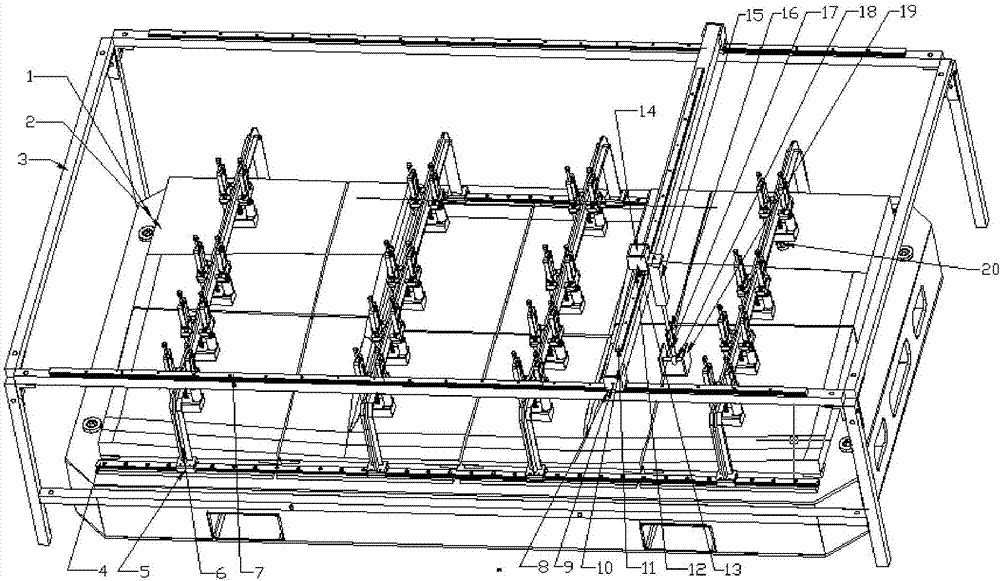

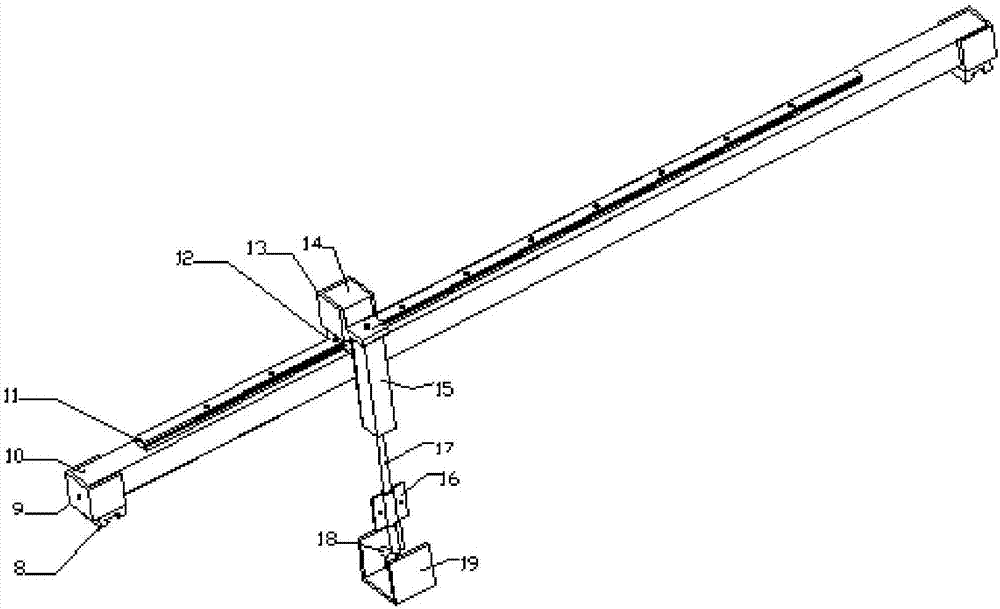

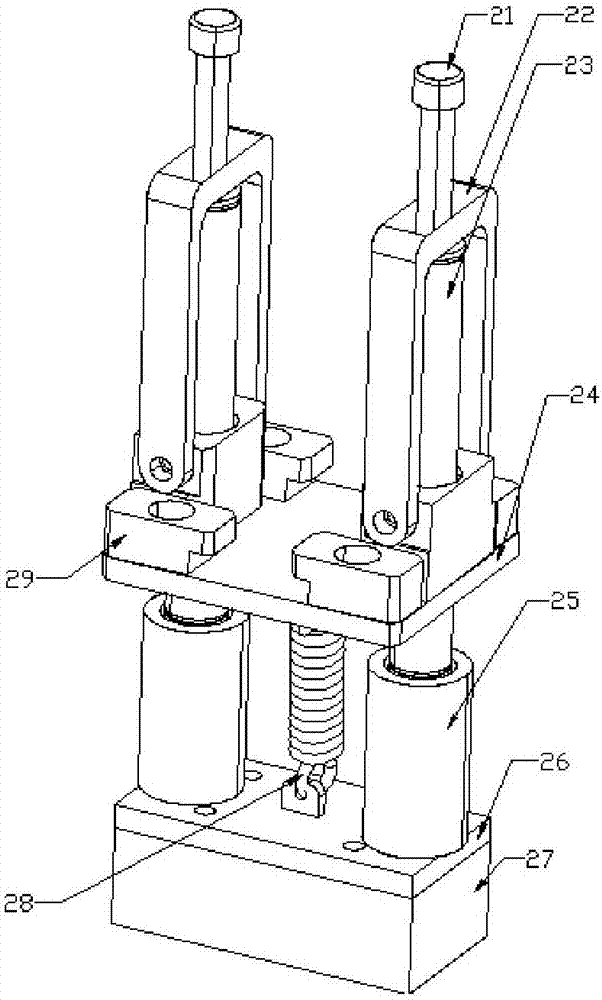

[0035] A measuring device suitable for the load-deformation mapping relationship of laminated plates, such as figure 1 As shown, it includes base 1, profiling support block 2, linear guide rail I4, pressurized support frame assembly, adjustable pressurized assembly, pressure sensor 20, deformation monitoring support frame assembly, displacement sensor 15 and deformation monitoring auxiliary assembly ,

[0036] The profiling support block 2 is at least 4 polyurethane blocks that can be spliced, and the polyurethane blocks are fixedly connected to the base 1 to form a profiling base that is the same shape as the laminate to support the laminate;

[0037] The linear guide rail I4 is symmetrically arranged on both sides of the base 1, and the pressurized support frame assembly can slide on the linear guide rail I4, and the adjustable pressurized as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com