A precision bolt connection torque-pretightening force mapping relationship measurement device

A technology of mapping relationship and measuring device, applied in the field of micro-miniature precision instruments, can solve the problems of specific requirements, low precision and inappropriateness of the test bolt structure and processing, so as to achieve a concise and clear transformation process, improve measurement accuracy, and avoid influences. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

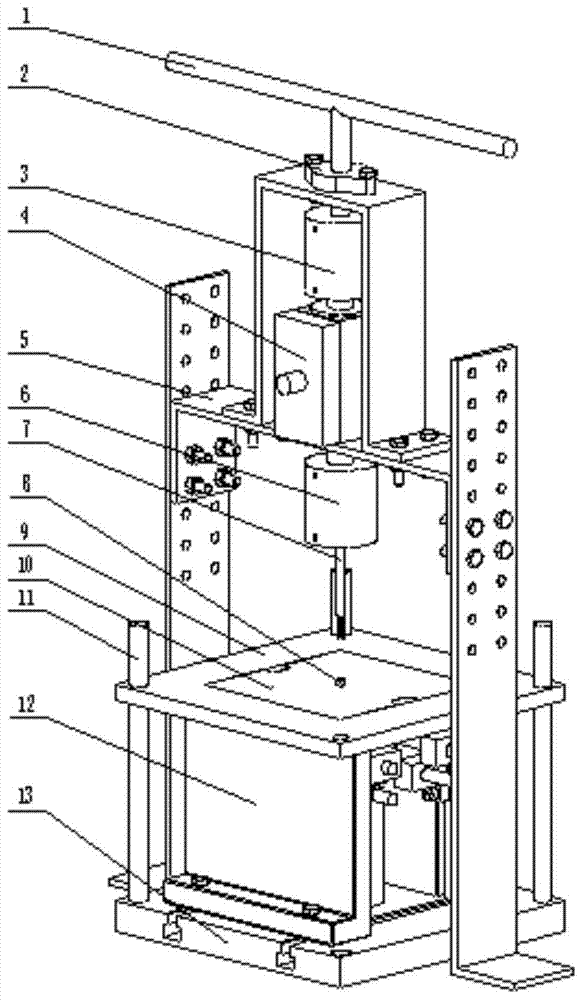

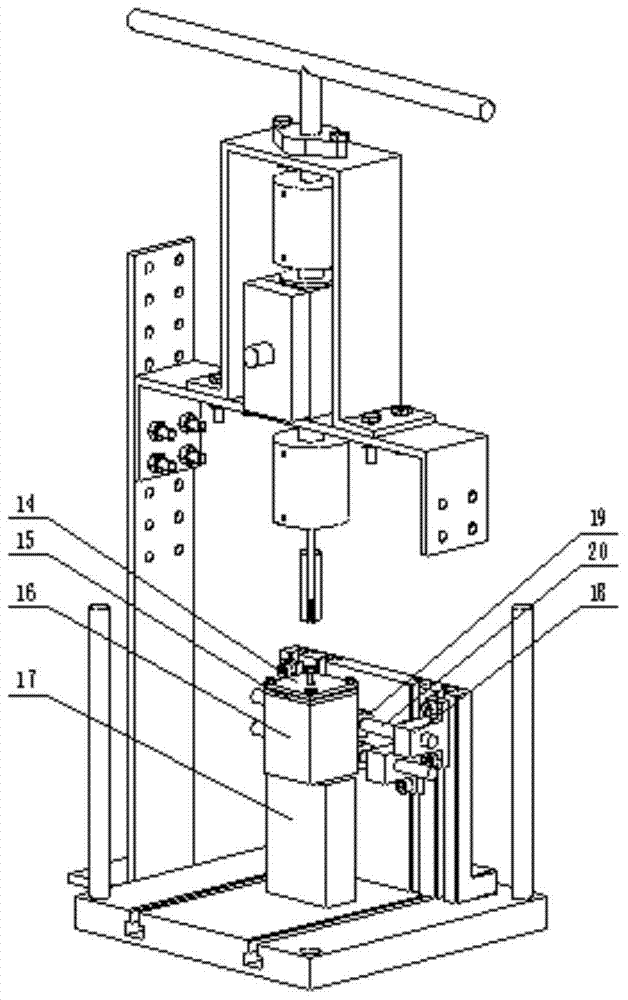

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0029] The present invention provides a precision bolt connection torque-pretightening force mapping relationship measuring device, and the technical solution for realizing the present invention is as follows:

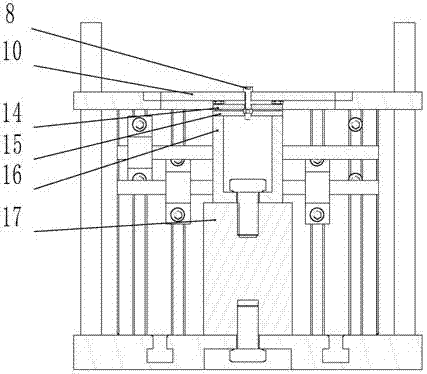

[0030] as attached figure 1 , 2 As shown, a precision bolt connection torque-tension measurement device includes: T-type wrench 1, self-centering bearing 2, torque sensor assembly, S-type high-precision sensor 17, gantry support 5, spring wrench 7, replaceable small Baffle plate 10, connecting column assembly, support frame assembly, limit assembly;

[0031] The T-type wrench 1 is a wrench welded from T-shaped cylindrical steel, and is installed on the gantry support 5 through a self-centering bearing 2, and is connected with a torque sensor 4 by a rigid coupling I3 so as to apply torque.

[0032] The torque sensor assembly includes a rigid coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com