Waste copper binding post pressing block recycling device

A terminal and recovery device technology, which is applied in the field of waste copper terminal briquette recovery device, can solve the problems of high impurity rate, poor quality of copper shavings, poor copper shavings recovery process level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

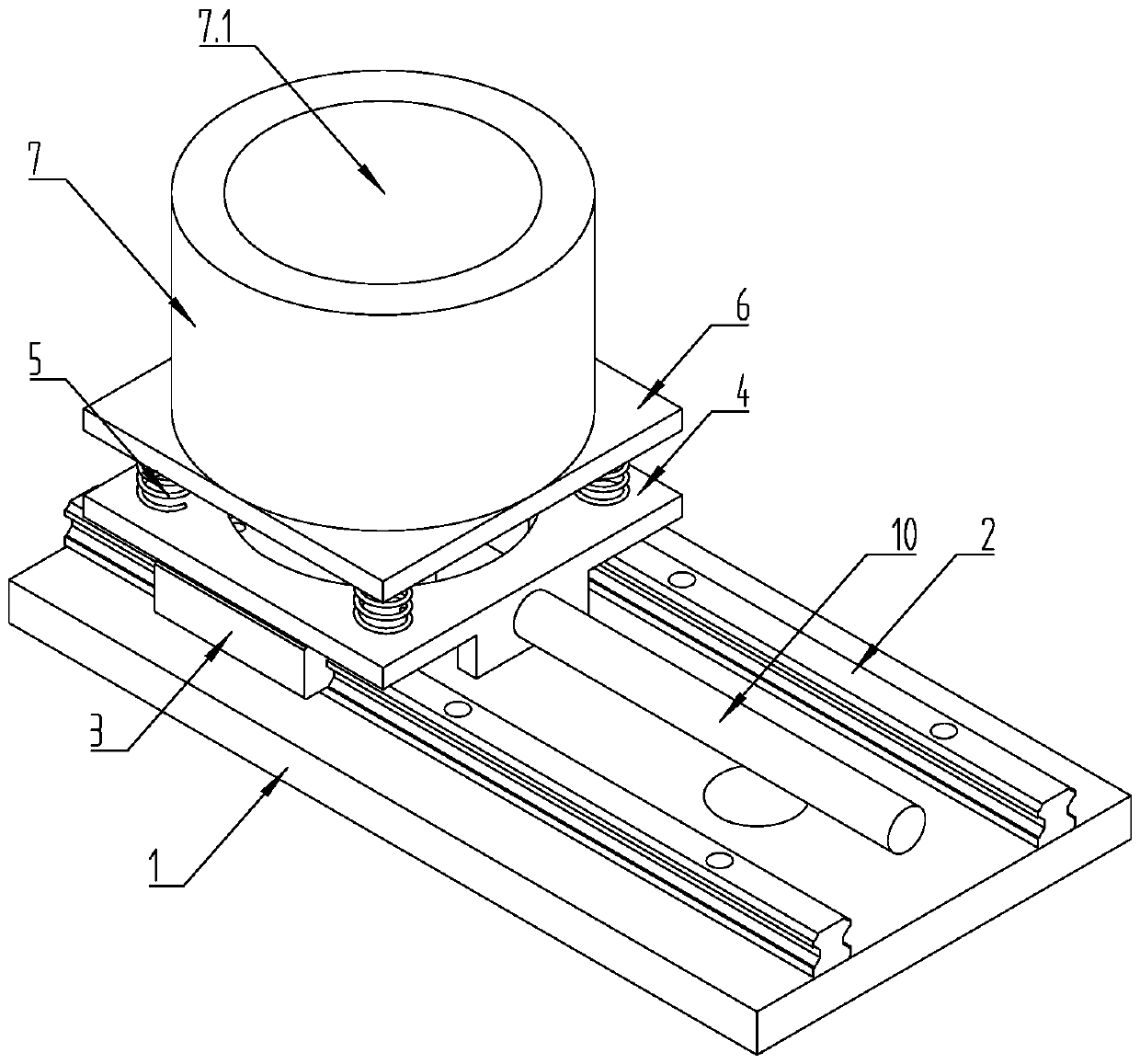

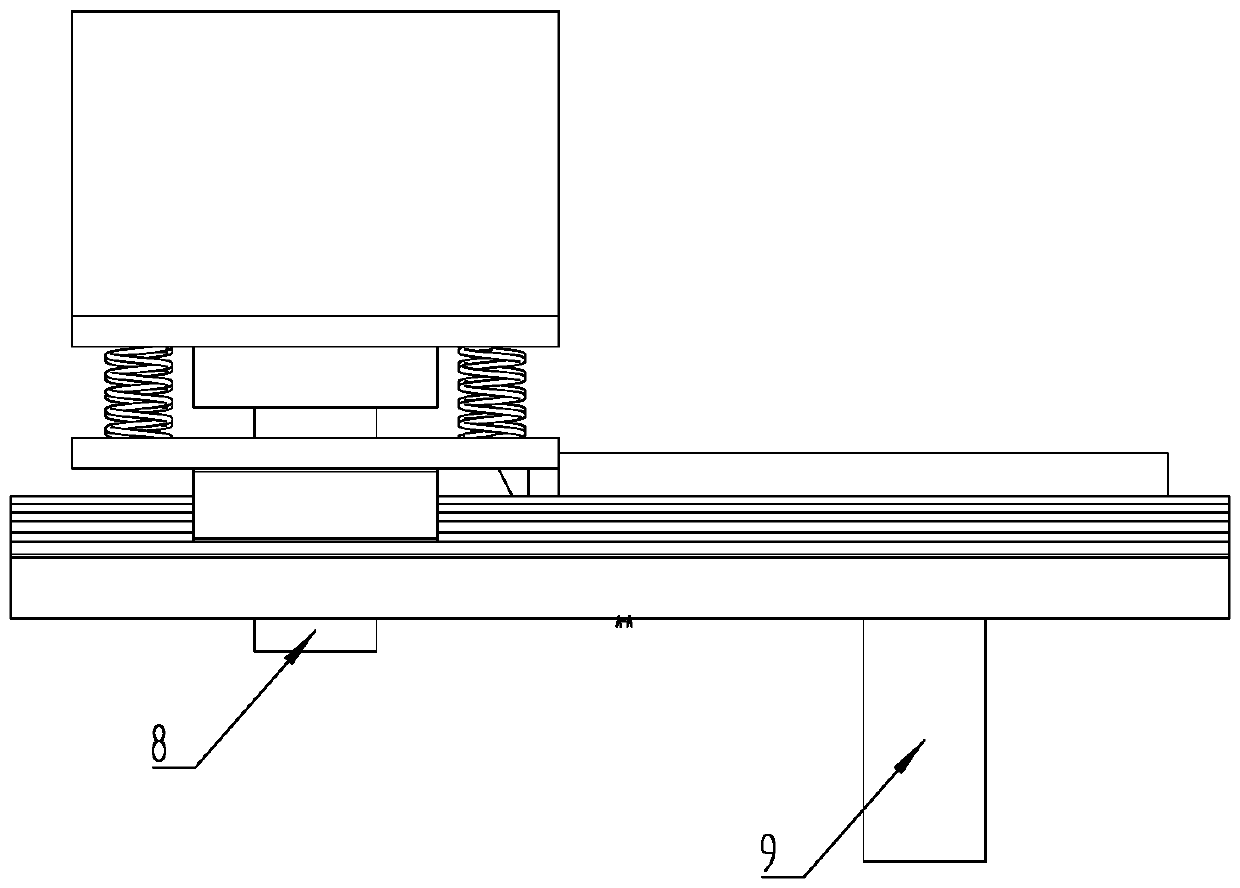

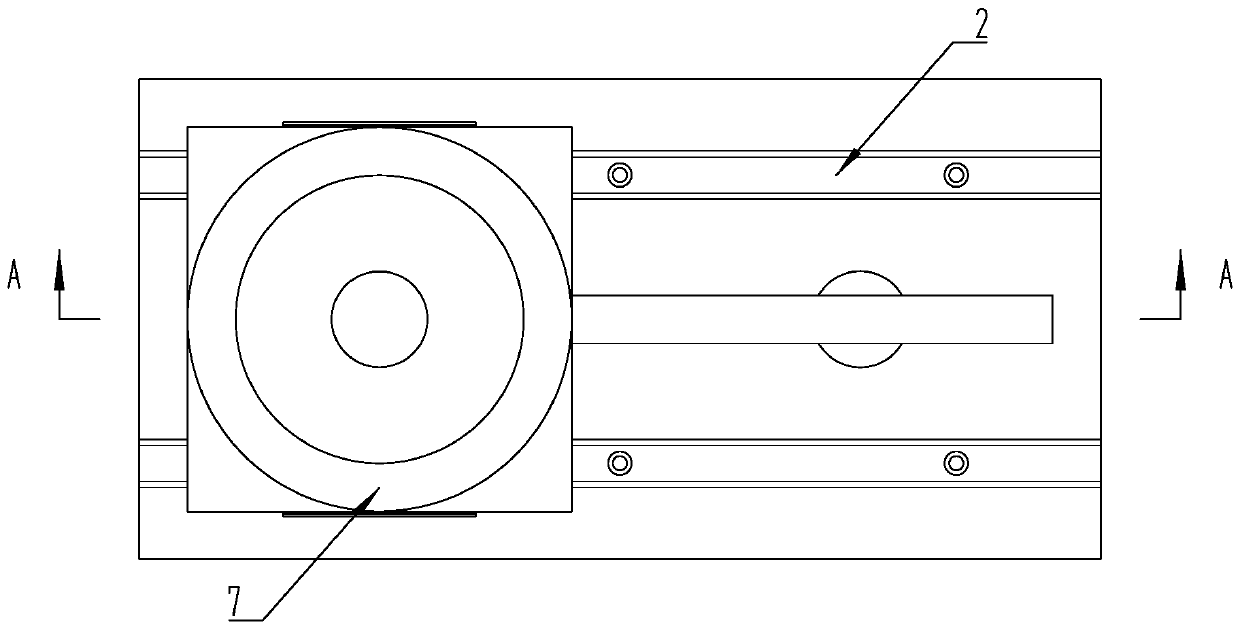

[0025] Such as Figures 1 to 4 As shown, a waste copper terminal compact recovery device includes a base 1, and the base 1 has a surface. The briquette recycling device also includes a feeding device, a briquette tooling, a hydraulic press and a manipulator. The briquetting tooling includes a sliding seat 4 , a bottom plate 6 , a spring 5 , a die 7 , a vibration motor, a first driving mechanism 8 , a second driving mechanism 10 and a third driving mechanism 9 . The sliding seat 4 is arranged on the table and forms a sliding connection with the base 1 along the first direction. The bottom plate 6 is arranged above the sliding seat 4 and is elastically supported by the spring 5 . The die 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com