Quick-assembling type connector terminal module

A technology of terminal modules and connectors, which is applied in the direction of connection, parts of connection devices, contact parts, etc., can solve the problems of complex production process, low efficiency, high cost, etc., achieve the effect of simple and fast assembly process and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

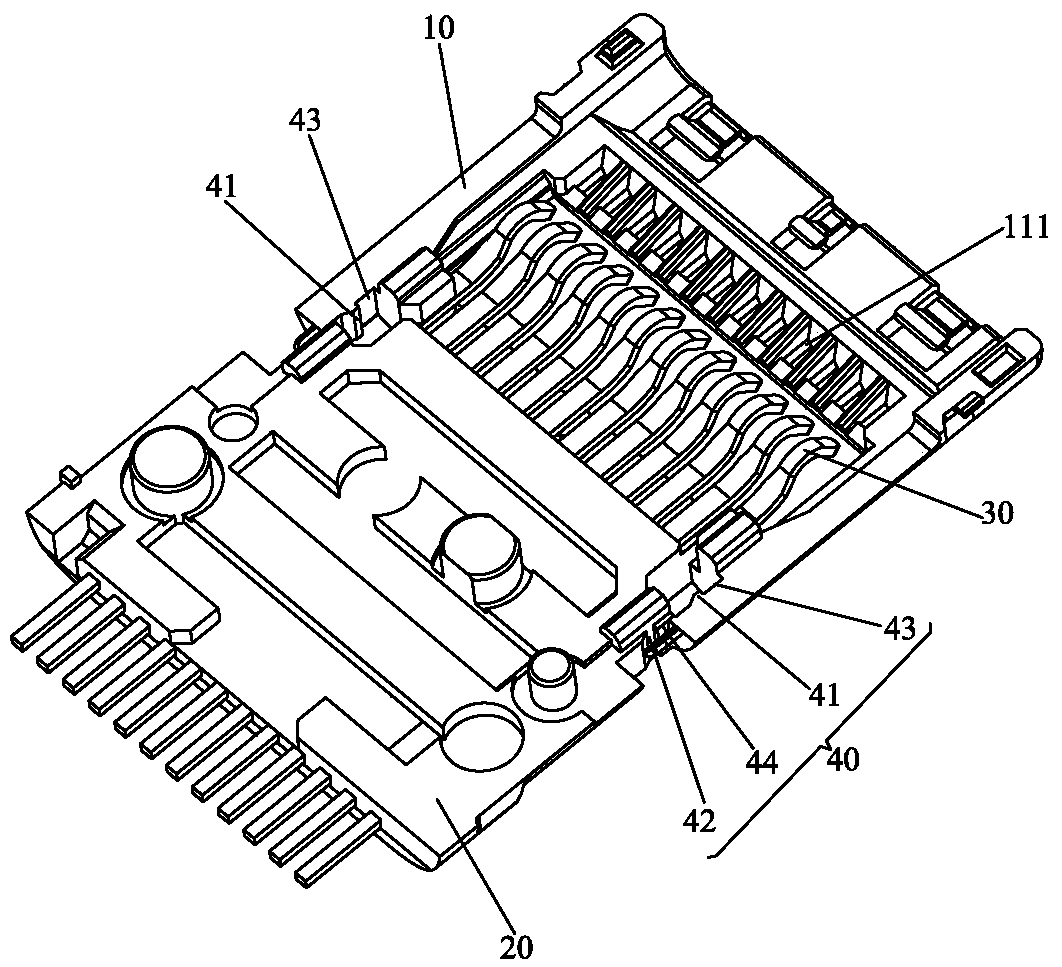

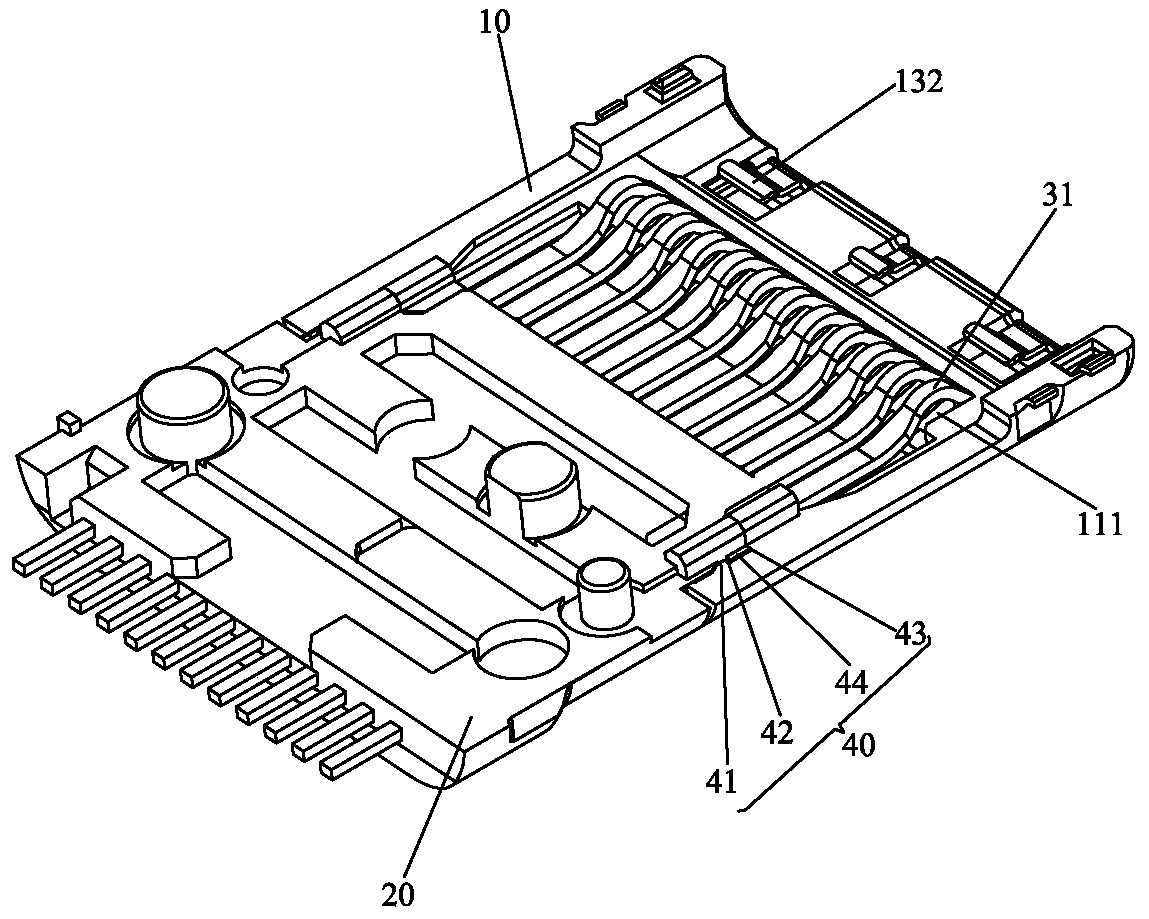

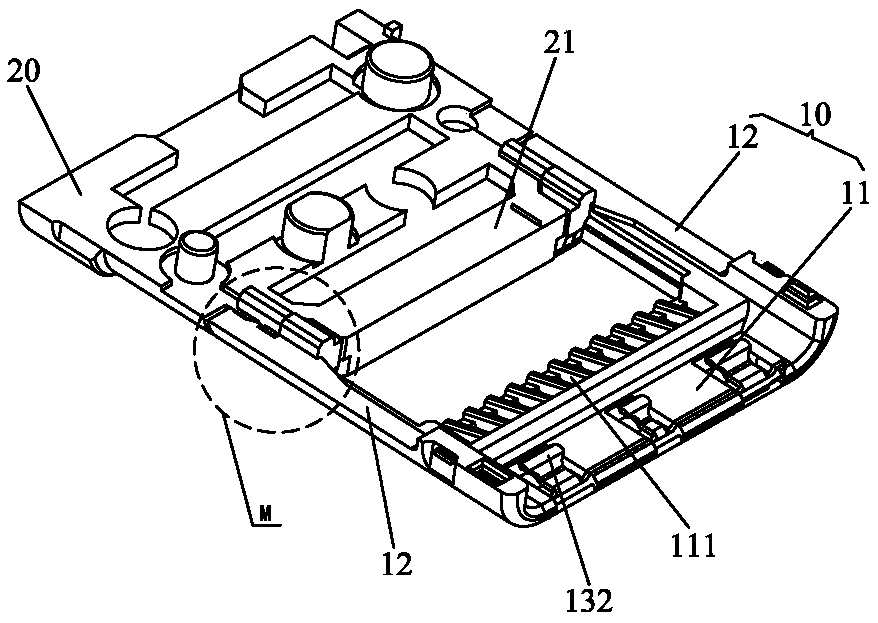

[0039] The present invention as Figure 1 to Figure 8 As shown, a terminal module of a quick-assembled connector includes a front terminal block 10, a rear terminal block 20, and a plurality of conductive terminals 30 embedded in the rear terminal block 20, wherein:

[0040] The front terminal block 10 includes a base plate 11 and two extension arms 12 integrally extended backward from both sides of the base plate 11. A plurality of concave positions 111 are arranged side by side at the front end of the base plate 11. The rear terminal block 20 is detachably installed on both sides. Between the extension arms 12, between the rear terminal base 20 and the extension arms 12, a position-limiting mechanism 40 for locking each other is provided; The front end of the contact portion 31 of the leg portion 33 of each conductive terminal 30 is bent downwards and inserted into the recess 111 .

[0041] The position-limiting mechanism 40 includes buckle blocks 41 arranged on the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com