Full-automatic central mosquito net hung on ceiling and having hoist ropes

A fully automatic mosquito net technology, applied to other seating furniture, household appliances, beds, etc., can solve the problems of affecting the appearance, easy to get dirty, and inconvenience of mosquito nets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

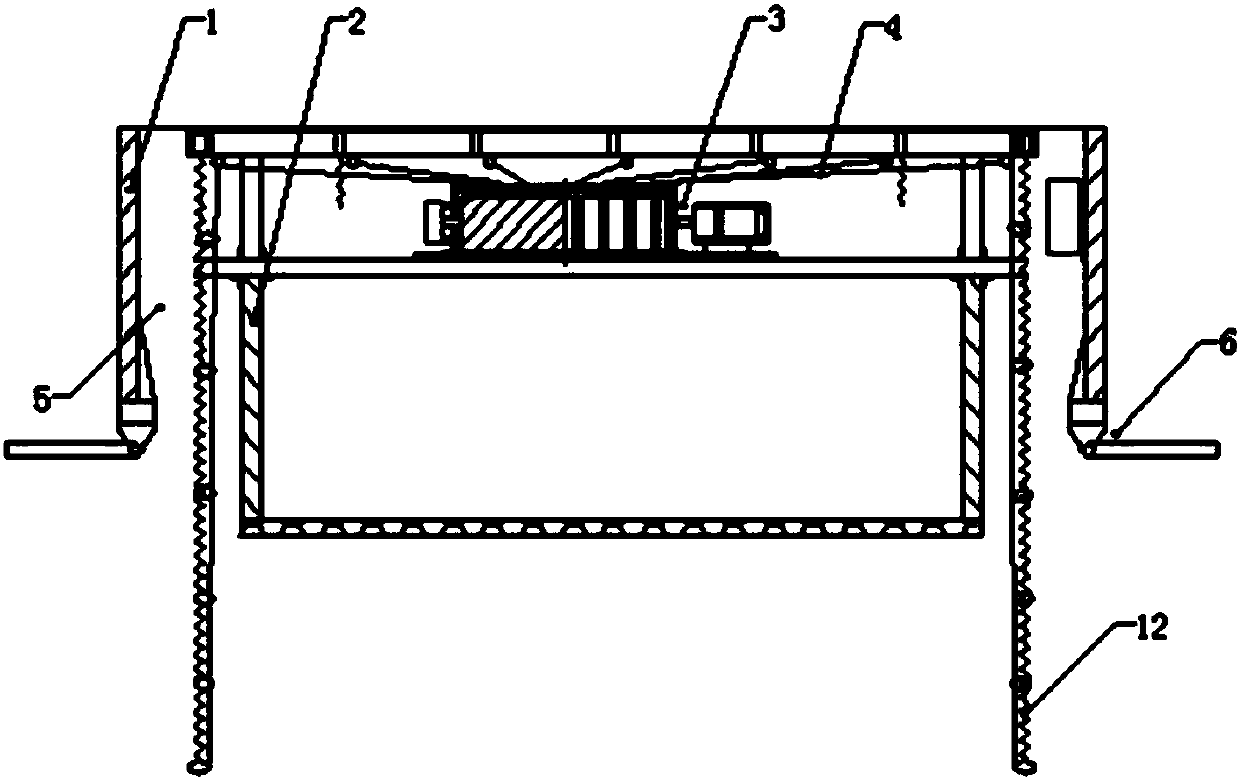

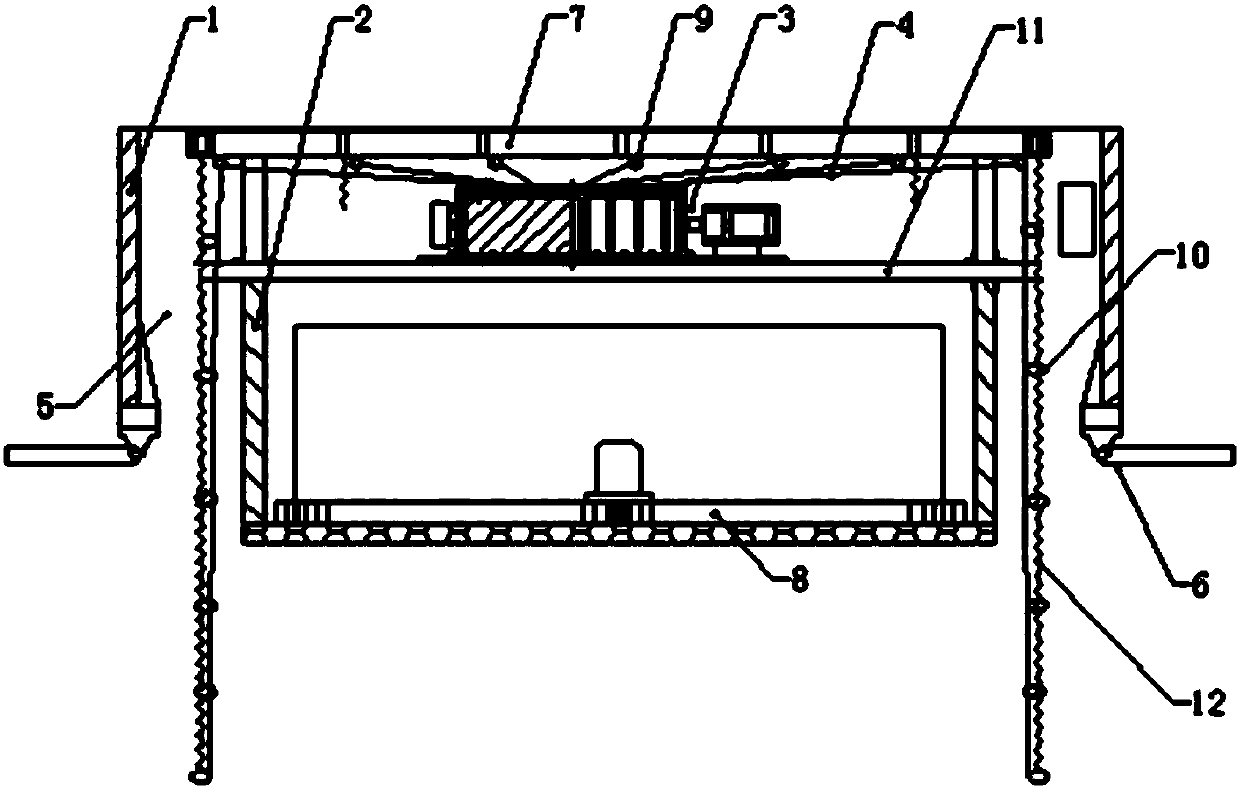

Embodiment 1

[0066] Such as Figure 10-13 As shown, the rope winding transmission device 3 includes a rope winding shaft 31, a rope winding shaft support seat 32, a rope winding transmission motor 33, a second stroke controller 34, and an overload protection torque switch 35; the rope winding shaft support seat 32 is provided with a cavity for accommodating the rope reel shaft 31, and its top offers a number of outlet holes 321; The winding rope 4 is retracted and unwound through the rope discharge hole 321 under the driving of the driving force. The second stroke controller 34 is used to control the number of turns of the winding rope shaft 31 to control the retracting length of the winding rope 4. The overload protection torque switch 35 is used for winding. The overload protection of rope drive motor 33. The specific embodiment of the overload torque switch 35 can refer to the overload protection torque switch in the applicant's previous Chinese patent application CN2017212951331.

Embodiment 2

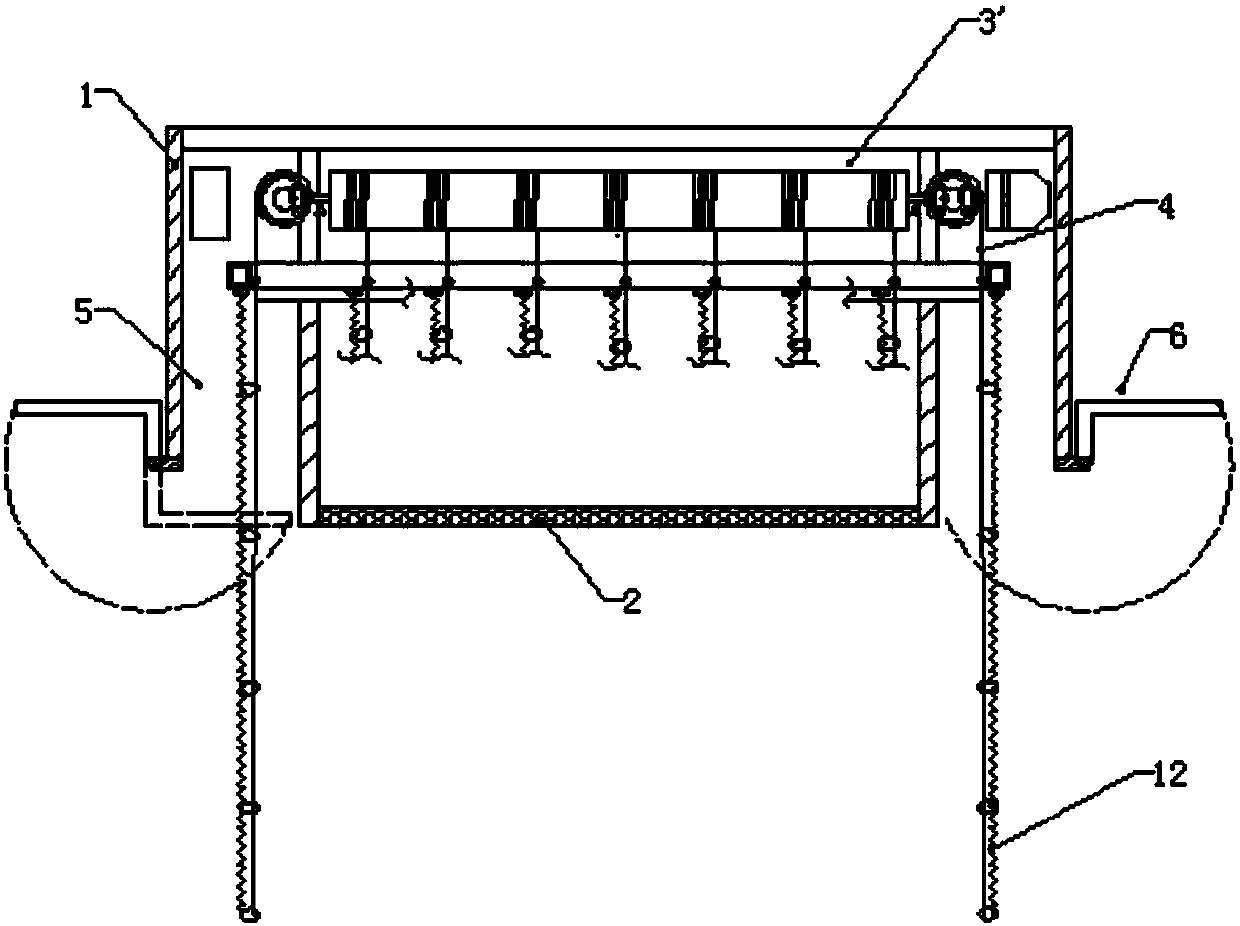

[0068] Such as Figure 14-15 As shown, the said reeling transmission device 3' includes four reeling shafts 31', several reeling shaft support seats 32', a reeling transmission motor 33', a second stroke controller 34', an overload protection torque switch 35', A number of bevel gears 36'; the rope winding shaft 31' is installed in the outer box shell 1 through the rope winding shaft supporting seat 32', and the bevel gear 36' is engaged and linked between the rope winding shafts 31', and the rope winding transmission motor 33' The load protection torque switch 35' is connected to one of the bevel gears 36', the second stroke controller 34' is used to control the number of turns of the winding shaft 31' to control the retractable length of the winding rope 4, and the overload protection torque switch 35' It is used for the overload protection of the winding rope drive motor 33'. The overload torque switch 35'-specific embodiments can refer to the overload protection torque sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com