Exhaust hood capable of automatically opening and closing air deflectors

An automatic switch and range hood technology, applied in the range hood field, can solve the problems of reducing the negative pressure area of the range hood, difficult cleaning, and increasing the risk of dripping oil, so as to improve the smoking effect, ensure uniqueness, and increase strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

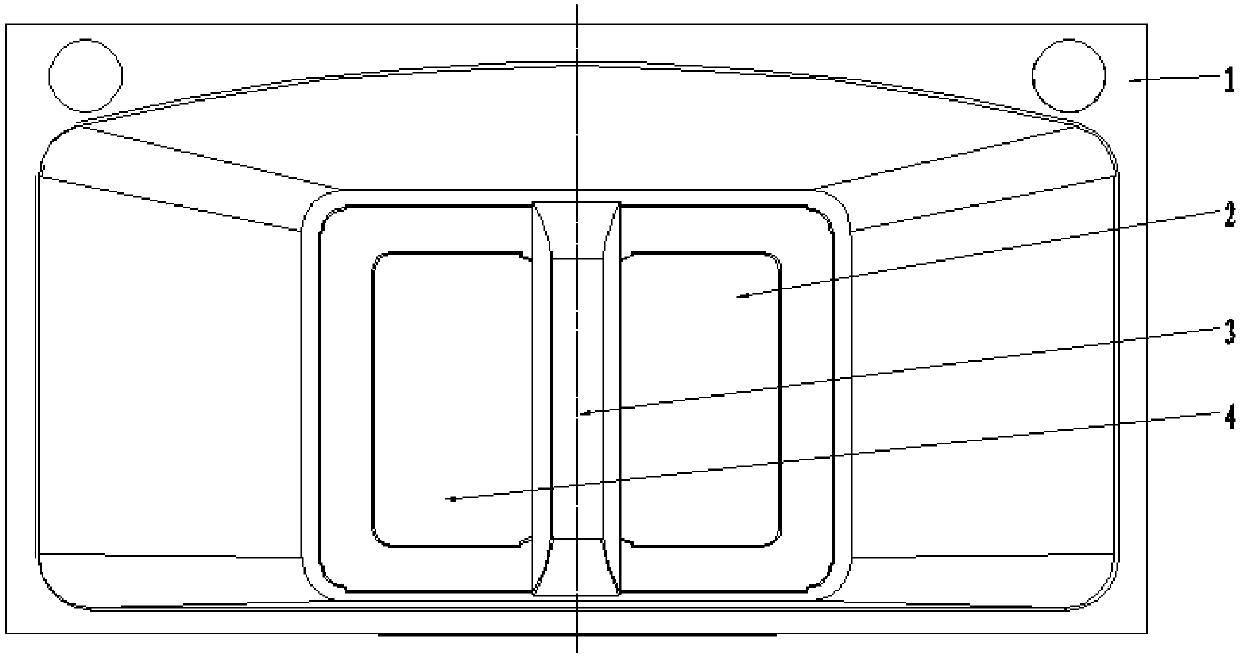

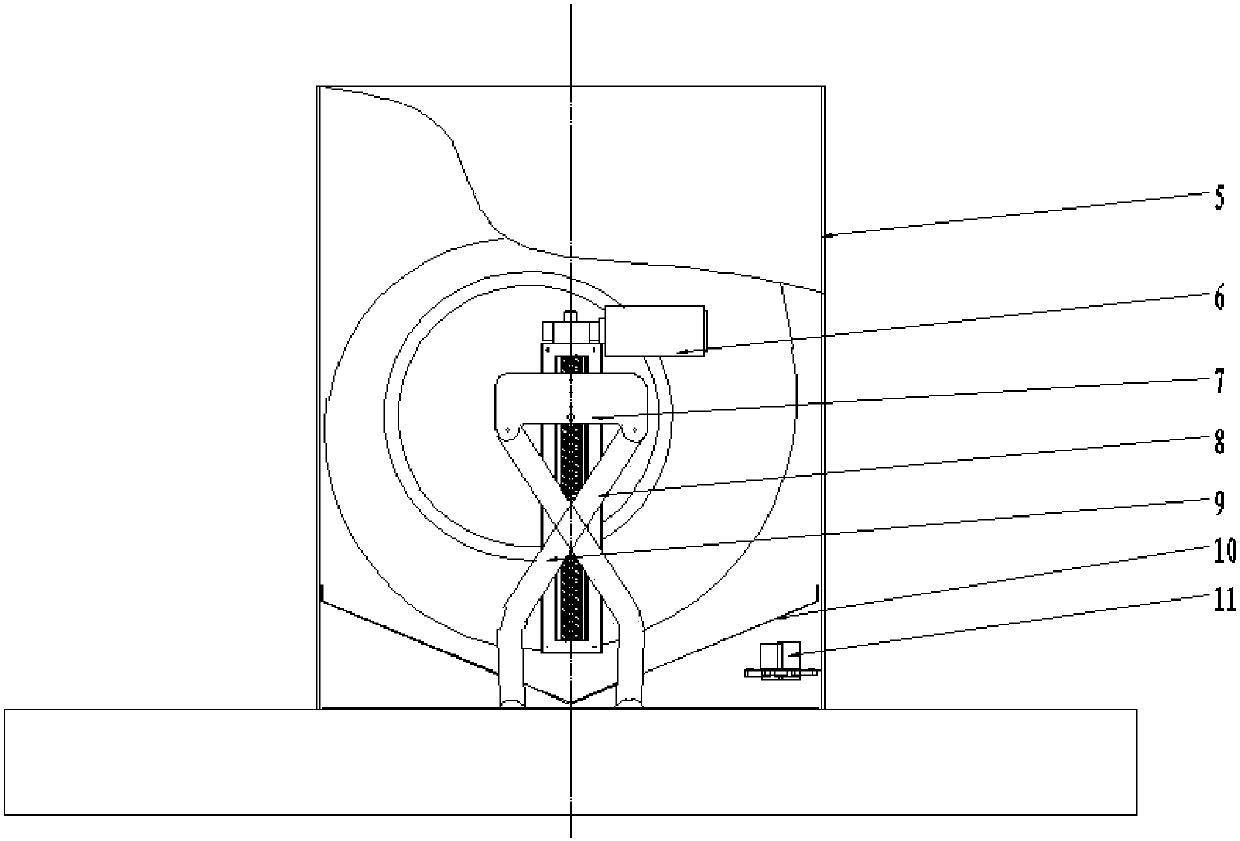

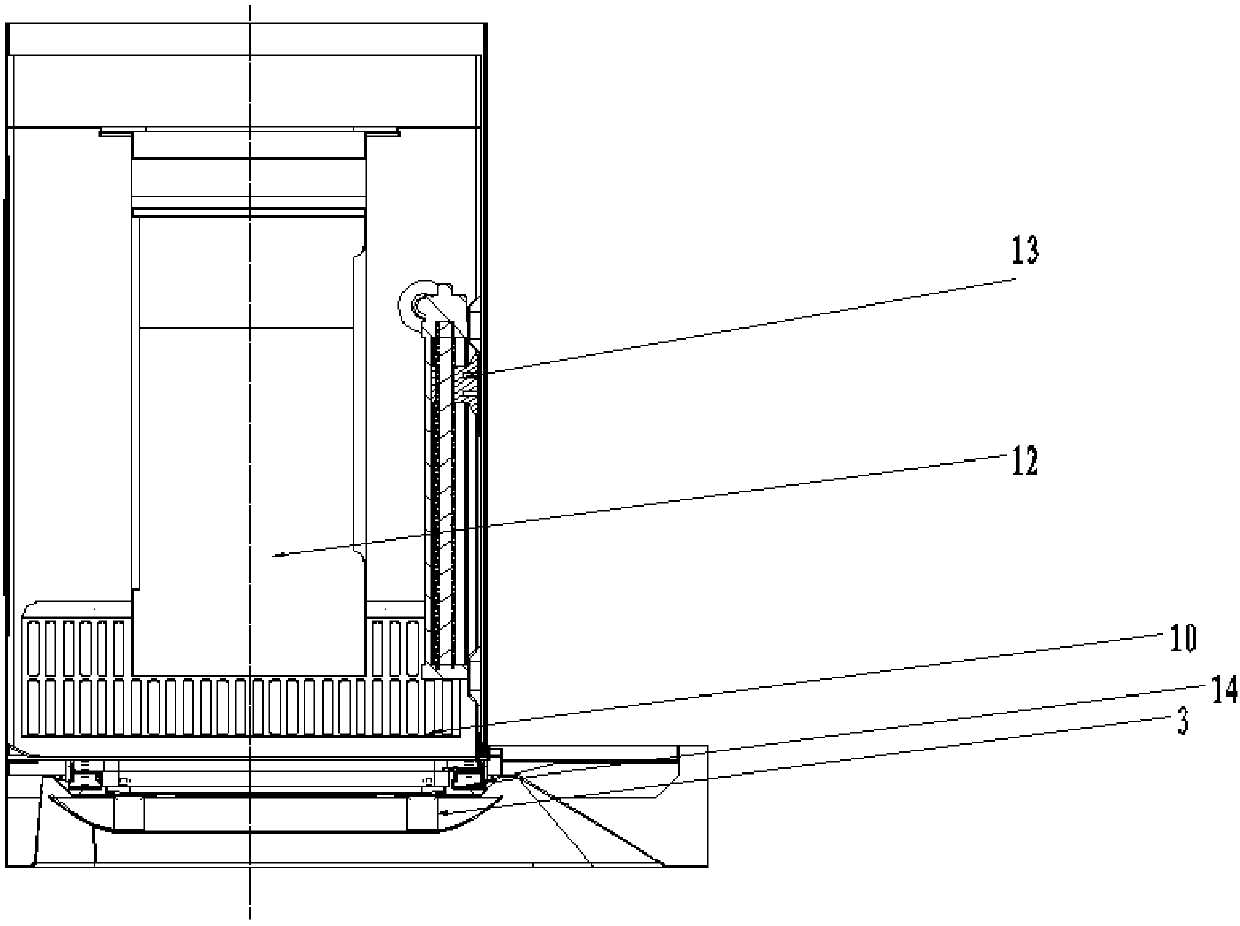

[0037] Embodiment 1: The range hood with automatic switch of the wind deflector mainly includes a smoke collecting hood assembly 1, a main engine shell assembly 5, and a fan assembly 12, and the main engine shell assembly 5 is located on the upper part of the smoke collecting hood assembly 1 , the fan assembly 12 is located inside the main engine shell assembly 5, and the slidable air deflector is provided on the fume collection hood assembly 1, and the air deflector is connected with a driving device, and the fume collection hood assembly 1 An air inlet is provided on the air inlet, and the driving device drives the wind deflector to slide between a first position for blocking the air inlet and a second position for opening the air inlet.

Embodiment 2

[0038] Embodiment 2: On the basis of Embodiment 1, the smoke collecting hood assembly 1 is provided with a slide rail assembly 14, and the air guide plate includes a right air guide plate 2 and a left air guide plate 4, and the right air guide plate The plate 2 and the left wind deflector 4 are slidably connected on the slide rail assembly 14 , and the right wind deflector 2 and the left wind deflector 4 slide along the slide rail assembly 14 .

Embodiment 3

[0039] Embodiment 3: On the basis of Embodiment 2, the fume collecting hood assembly 1 includes an oil cup 3, a right fixed frame 17 and a left fixed frame 18, and the lower part of the fan assembly 12 is provided with a filter screen 10, an oil cup 3 Located below the filter screen 10, the oil cup 3 is located in the middle of the right wind deflector 2 and the left wind deflector 4, and the right fixed frame 17 and the left fixed frame 18 are combined with the smoke collecting hood assembly 1 through rigid links.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com