range hood

A technology for range hoods and hoods, which is applied in the directions of removing oil fume, household heating, lighting and heating equipment, etc., can solve the problems of inability to completely absorb oil fume, e-liquid rising and overflowing, and the power source cannot be aimed at the stove, etc. Eliminate the escape of oil smoke, easy installation, and improve the effect of smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

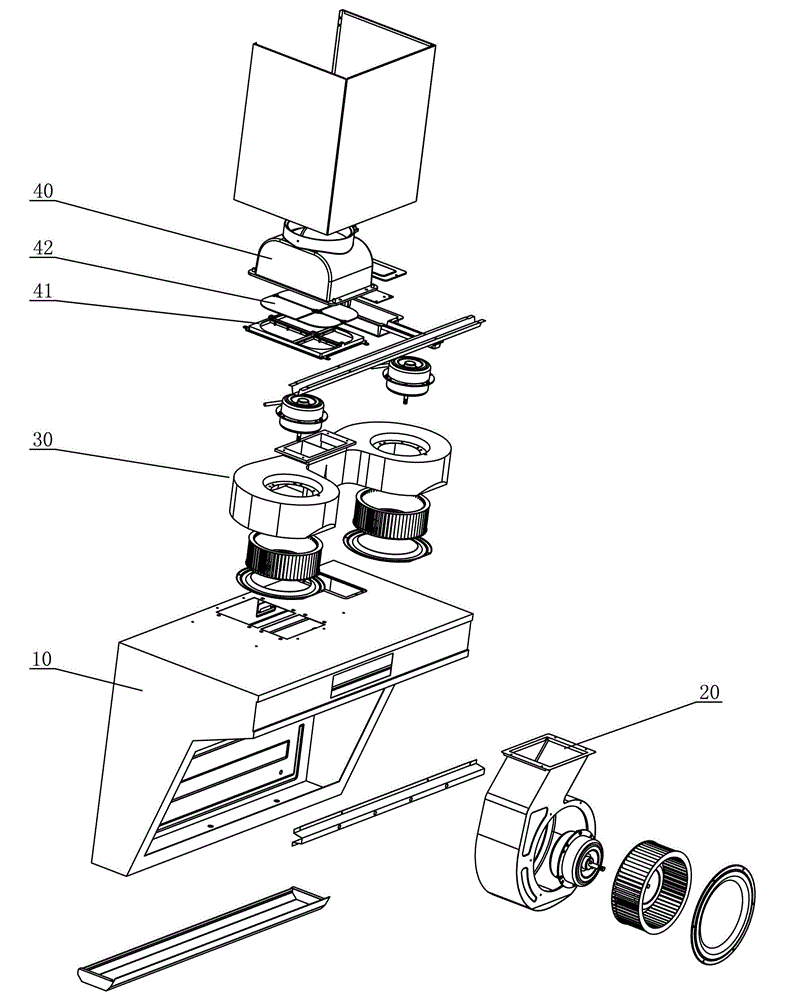

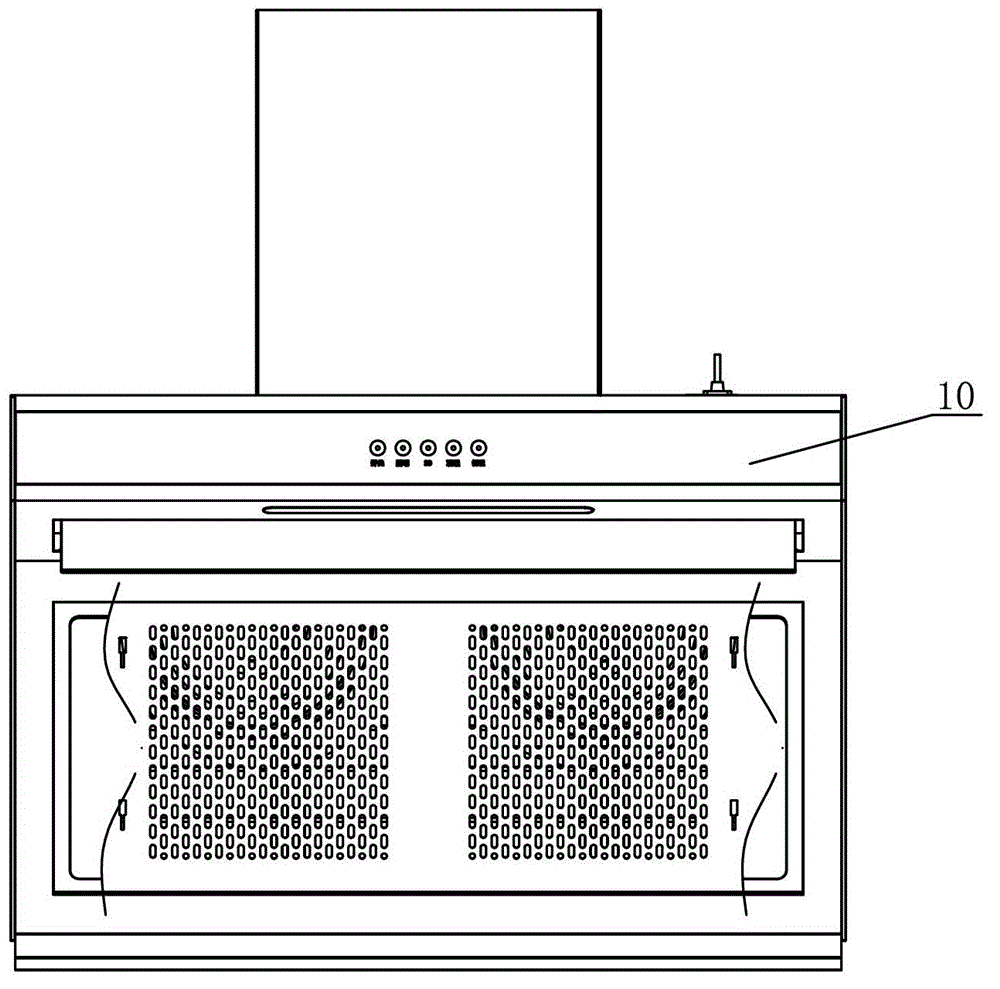

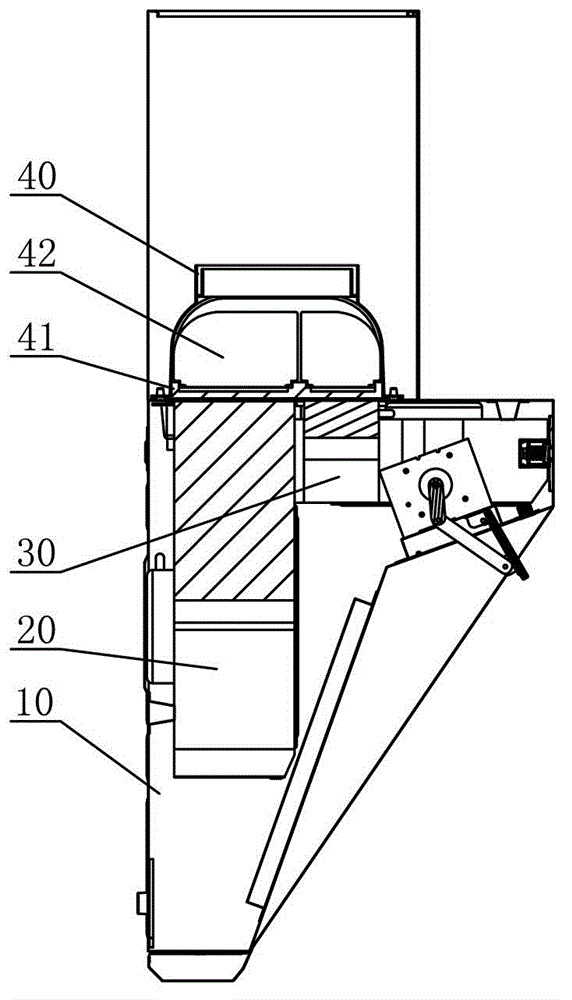

[0031] see Figure 1-Figure 10 , the range hood includes a hood main body 10 provided with a smoking port and a smoke exhaust port (no label in the figure), the inside of the hood main body 10 is provided with a first wind cabinet 20 for smoking on the side of the smoking port, and The inner top is provided with a second wind cabinet 30 for smoking at the top of the smoking port.

[0032] The exhaust ends of the first wind cabinet 20 and the second wind cabinet 30 communicate with the smoke exhaust port through the one-way smoke exhaust channel respectively.

[0033] The first wind cabinet 20 is composed of at least one group of fans, and each group of fans corresponds to a group of independent exhaust ends; the second wind cabinet 30 is composed of at least one group of fans, and each group of fans corresponds to a group of independent exhaust ends. In this embodiment, the first air cabinet 20 is composed of a group of fans, with a group of independent exhaust ends, such as ...

no. 2 example

[0037] see Figure 11-Figure 13 , the main difference between this range hood and the first embodiment is that the first wind cabinet 20 is composed of two groups of fans, and has two groups of independent exhaust ends, and the two groups of exhaust ends are respectively connected to the rear of the air guide cover 40 The two groups of one-way exhaust passages on the side are connected. Similarly, if one group of fans of the first wind cabinet 20 is turned on separately, it will not interfere with each other's exhaust ends, and will not cause turbulence to reduce the smoking effect, let alone Air flow backflow will be formed. The range hood forms a three-dimensional or rectangular three-dimensional smoking on the cooktop through the combination of top suction and side suction, which greatly improves the smoking effect, prevents the fume from escaping to the greatest extent, and solves the existing problems of this product on the market today. insufficient.

[0038] Other unm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com