A substitute for c.i. disperse red 167 dye with a smaller metamerism index

A metamerism and disperse red technology, which is applied in the field of preparation of disperse red dye mixtures, can solve the problems of many components, insufficient dyeing depth, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

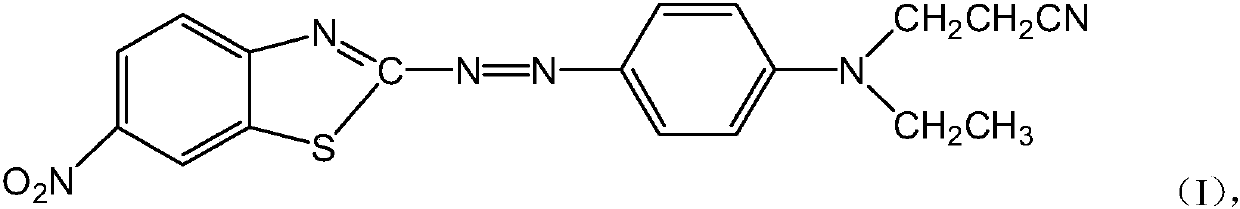

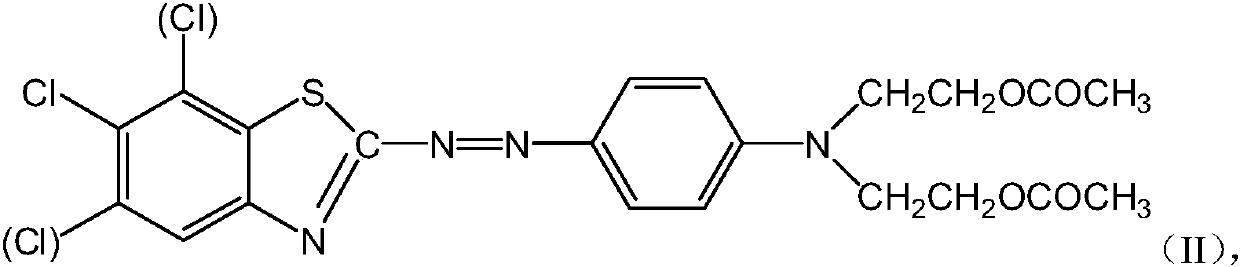

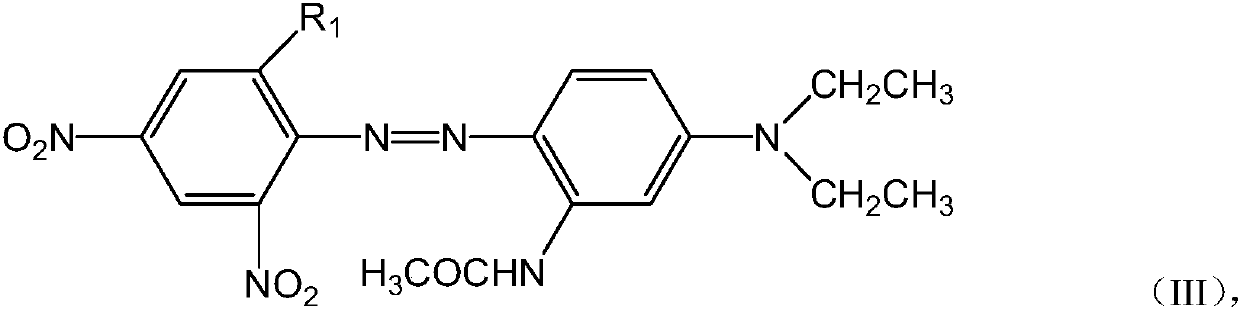

Image

Examples

Embodiment 1~15

[0022] Mix the original dye A, the original dye B, the original dye C and the auxiliary agent in a certain proportion, add a certain amount of water, grind and disperse with a grinder and dry to obtain the finished product, and obtain the disperse red dye mixture 1-15, as shown in Table 1 Show. This dye can provide fabrics with excellent washing fastness and sublimation fastness. When blended in a certain ratio, the dyeing shade of the mixture is very close to C.I. Disperse Red 167. When D65 is the main light source, A light source, TL84 light source and The metamerism index of CWF light source is very small.

[0023] Table 1

[0024]

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com